Choosing the right 3D printer in 2025 requires careful consideration, especially if you want to buy a 3D printer that suits your needs. Only 13% of users fully utilize 3D printing, highlighting the importance of selecting a model that matches your skills and objectives. Focus on factors like print speed, material compatibility, and price. Prioritize features that align with your needs to maximize value and efficiency when you decide to buy a 3D printer.

Key Takeaways

- Think about why you need a 3D printer. Is it for fun or work? This helps you pick the right one for your needs.

- Check what materials the printer can use. Make sure it works with the materials you want for your projects to get good results.

- Look at the printer's size and speed. Bigger printers can make larger items. A good mix of speed and detail gives better prints.

How to Identify the Best 3D Printer for Your Needs

Personal vs. Professional Use

When choosing the best 3D printer for your needs, you must first determine whether you plan to use it for personal or professional purposes. Personal use often involves hobbies, education, or small-scale projects, while professional use typically demands higher precision, durability, and scalability. Understanding this distinction helps you narrow down your options effectively.

For personal use, affordability and ease of operation are key. Many personal 3D printers, such as entry-level FDM models, offer user-friendly interfaces and sufficient capabilities for tasks like crafting, prototyping, or educational projects. On the other hand, professional use often requires advanced features like higher resolution, larger build volumes, and compatibility with a broader range of materials. For example, SLA printers, with their ability to achieve layer thicknesses as fine as 25 microns, are ideal for creating high-detail models like jewelry. In contrast, FDM printers, which typically produce layers between 100 and 400 microns, are better suited for prototyping and functional parts.

|

Technology |

Typical Layer Thickness |

Use Case |

|---|---|---|

|

SLA |

25 – 100 microns |

High-detail models like jewelry |

|

FDM |

100 – 400 microns |

Prototyping and functional parts |

By identifying your primary use case, you can focus on the features that matter most, ensuring you invest in the best 3D printer for your specific requirements.

Common Applications of a 3D Printer

The versatility of 3D printing has expanded its applications across various industries and personal projects. In 2025, some of the most common uses include industrial-grade applications like metal, plastic, and ceramic printing, as well as personal projects in education, entertainment, and architecture. Whether you aim to create intricate jewelry designs or functional prototypes, understanding these applications can guide your decision.

|

Application Type |

Market Segment |

|---|---|

|

Metal Printing |

Industrial Grade |

|

Plastics Printing |

Industrial Grade |

|

Ceramics Printing |

Industrial Grade |

|

Education |

Personal 3D Printers |

|

Entertainment |

Personal 3D Printers |

|

Jewelry |

Personal 3D Printers |

|

Architecture |

Personal 3D Printers |

|

Others |

Personal 3D Printers |

If you’re looking for the best 3D printer for beginners, consider models designed for education or entertainment. These printers often prioritize ease of use and affordability. For industrial-grade applications, focus on advanced technologies like SLS or SLA, which deliver the precision and durability required for professional projects.

Material Compatibility and Preferences

Material compatibility plays a crucial role in selecting the best overall 3D printer. The materials you choose must align with your design goals and intended applications. For instance, if you plan to create functional parts, you’ll need a printer compatible with durable materials like ABS or nylon. For artistic or detailed projects, resin-based materials used in SLA printers may be more suitable.

Several factors highlight the importance of material compatibility:

- Materials must suit the application to achieve design objectives.

- Material properties influence the transition from concept to production.

- Evaluating material properties alongside the manufacturing process ensures desired characteristics.

- Additive manufacturing (AM) introduces unique requirements, making material compatibility essential.

To find the best 3D printer for quality, prioritize models that support a wide range of materials. This flexibility allows you to experiment with different projects and achieve optimal results. Always consider the availability and cost of materials, as these factors can impact your long-term expenses.

Types of 3D Printers to Consider in 2025

FDM Printers: Affordable and Versatile

Fused Deposition Modeling (FDM) printers remain the most popular choice for users seeking affordability and versatility. These printers use thermoplastic filaments, which are melted and extruded layer by layer to create 3D objects. If you’re looking to buy a 3D printer for personal or educational use, FDM printers offer unmatched value. Their ability to work with a wide range of materials, including PLA, ABS, and carbon fiber composites, makes them suitable for diverse applications such as prototyping, functional parts, and even artistic projects.

Tip: FDM printers are ideal for beginners due to their user-friendly operation and low maintenance costs. They also serve as the best large format 3D printer option for creating bigger models without breaking the bank.

|

Evidence Type |

Details |

|---|---|

|

Affordability |

FDM is recognized as the most economical method for producing custom thermoplastic parts. |

|

Material Options |

Users can select from a wide range of thermoplastics, enhancing versatility across industries. |

|

Application Suitability |

Suitable for various applications, including aerospace, automotive, and healthcare. |

Continuous advancements in FDM technology have improved print quality and material compatibility, making these printers a reliable choice for both hobbyists and professionals. If you prioritize affordability and versatility, FDM printers are the best overall 3D printer for your needs.

Emerging 3D Printing Technologies in 2025

The future of 3D printing is shaped by innovations that address industry challenges and consumer demands. Hybrid materials engineered for specific applications are revolutionizing sectors like medical and aerospace. Sustainability is also a growing focus, with manufacturers prioritizing energy efficiency and waste reduction.

- Prototyping remains the leading application of 3D printing, with 66% of users citing it as their primary use.

- Tooling and end-use production are gaining traction, with 21% of respondents using 3D printing for end-use production.

- Key industries driving advancements include aerospace, automotive, and medical, with emerging interest from food, fashion, and bioprinting.

- AI-enabled capabilities improve consistency and quality control in 3D printing processes.

- Smart materials (4D printing) open new applications, particularly in healthcare.

- Sustainability initiatives make 3D printing a greener alternative to traditional manufacturing methods.

Callout: The integration of AI and IoT in 3D printing processes is expected to redefine manufacturing efficiency and open new possibilities for innovation.

Emerging technologies like AI-driven systems and smart materials will enhance the capabilities of 3D printers, making them more versatile and sustainable. If you’re planning to buy a 3D printer in 2025, keep an eye on these advancements to ensure your investment aligns with future trends.

Features to Look for in the Best 3D Printers

Build Volume and Print Size

When evaluating a 3D printer, build volume plays a critical role in determining the size of objects you can create. A printer with a build volume of 200 x 200 x 200 mm is ideal for small engineering prototypes or personal projects. Smaller printers often provide advantages like a more rigid frame, shorter belt runs, and a compact footprint, making them easier to manage in limited spaces.

|

Specification |

Description |

|---|---|

|

Build Volume |

A printer designed around a 200 x 200 x 200 mm build volume is optimal for small engineering prototypes. |

|

Benefits of Size |

Smaller printers can offer advantages such as shorter belt runs, a more rigid frame, and a smaller footprint. |

If you plan to buy a 3D printer for larger projects, consider models with extended build volumes. These allow you to create bigger prototypes or multiple smaller parts in a single print job, saving time and effort.

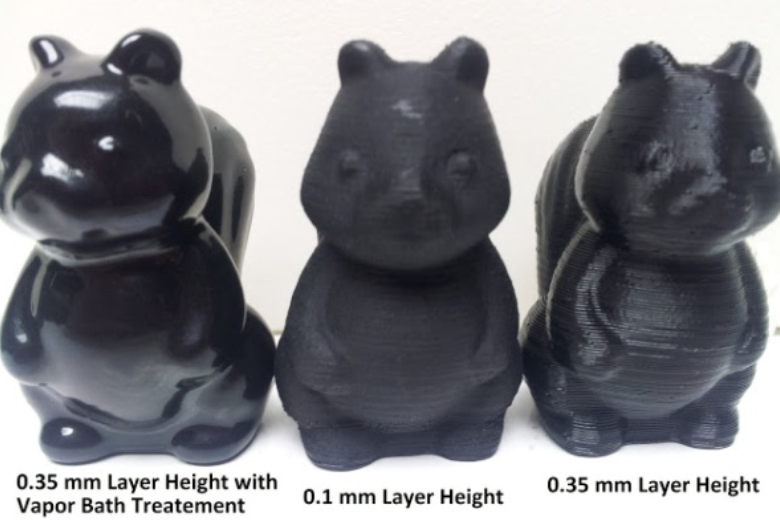

Print Speed and Resolution

Print speed and resolution significantly impact your 3D printing experience. High-speed printers excel at fast printing but may compromise detail accuracy. Conversely, high-resolution models deliver finer details and optimized material usage, though they take longer to complete a job.

|

Aspect |

High Speed |

High Quality |

|---|---|---|

|

Layer Resolution |

Coarser |

Finer |

|

Detail Accuracy |

Lower |

Higher |

|

Time Efficiency |

Better |

Slower |

|

Material Use |

Possible Increased Waste |

Optimized Usage |

For the best 3D printer for quality, prioritize models that balance speed and resolution. This ensures you achieve excellent print quality without excessive delays.

Connectivity Options for Modern 3D Printers

Modern 3D printers offer various connectivity options to streamline your workflow. Wi-Fi, USB, and Ethernet connections are standard, enabling seamless file transfers and remote monitoring. Some advanced models integrate with cloud-based platforms, allowing you to manage prints from anywhere. These features enhance your setup experience and simplify the printing process.

Tip: Choose a printer with multiple connectivity options to ensure compatibility with your existing devices and software.

Reliable connectivity not only improves ease of use but also reduces downtime caused by file transfer issues. This is especially important for professionals managing multiple projects simultaneously.

Software Compatibility and Ease of Use

The software ecosystem of a 3D printer can make or break your setup experience. Intuitive user interfaces and reliable software simplify the printing process, reducing the learning curve for beginners. Web-based training materials and secure systems further enhance ease of use, making it easier to access and manage your 3D printing data.

- Intuitive user interfaces significantly enhance the operation of 3D printers.

- Reliable and feature-rich software is crucial for streamlining the printing process.

- Low-maintenance requirements contribute to increased productivity and reduced downtime.

For the best overall 3D printer, look for models with robust software support and user-friendly interfaces. These features ensure a smooth setup and operation, allowing you to focus on your projects rather than troubleshooting.

Finding the Best Budget 3D Printer

Entry-Level Options for Beginners

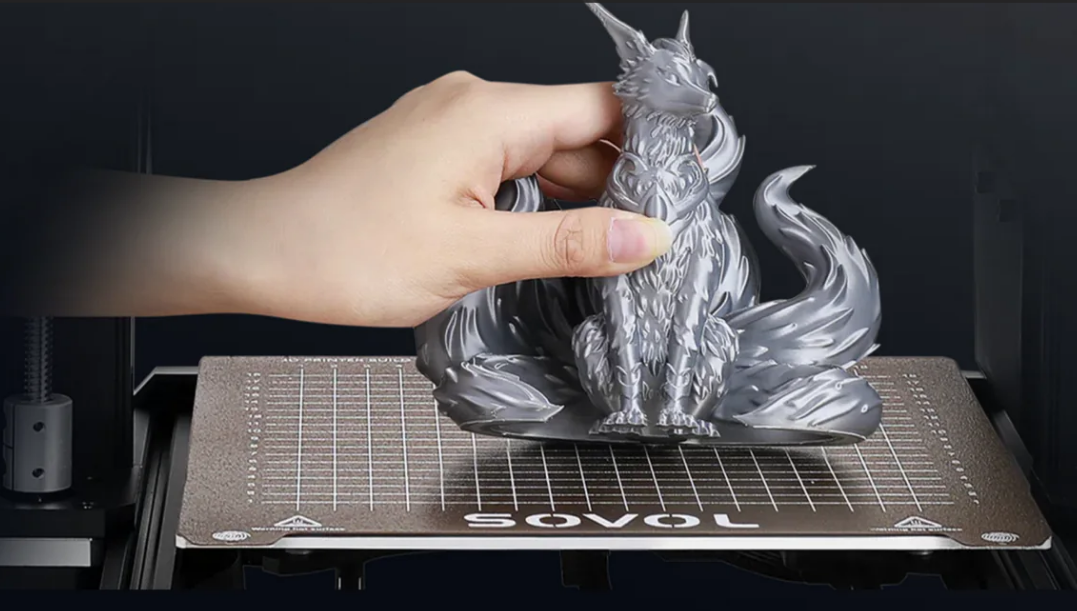

If you’re new to 3D printing, entry-level models provide an excellent starting point. These budget 3D printers deliver acceptable quality at a great price, making them ideal for beginners exploring the technology. Models like the Sovol SV08 offer high print resolution, enabling you to create detailed models without breaking the bank. They balance print speed and quality, ensuring efficient results for novice users. Additionally, their compatibility with materials like PLA and ABS allows you to experiment with various projects, from simple prototypes to decorative items.

A benchmarking study on entry-level 3D printers reveals that these systems can produce quality parts for conceptual models and personalized objects. While performance varies across models, some entry-level printers approach the quality of more expensive systems, making them a viable choice for beginners.

Mid-Range Printers for Enthusiasts

For enthusiasts seeking more advanced features, mid-range 3D printers offer a perfect balance between affordability and performance. These models, typically priced between $500 and $2000, provide larger build volumes and improved print quality compared to entry-level options. Features like dual extruders and Wi-Fi connectivity enhance their usability, allowing you to tackle more complex projects with ease. Faster printing speeds also make these printers efficient for hobbyists working on multiple designs.

High-End Models for Professionals

High-end 3D printers cater to professionals who demand precision and reliability. These models excel in producing intricate designs and functional parts for industries like architecture, healthcare, and robotics. For example, 3D printing has revolutionized architectural workflows by enabling rapid prototyping and collaborative design.

Hidden Costs to Watch Out For

When you buy a 3D printer, consider the hidden costs that may affect your budget. Material expenses, such as filaments or resins, can add up over time. Replacement parts, like nozzles or build plates, also contribute to ongoing costs. Additionally, some printers require proprietary software or accessories, which may increase your total expenditure. To find the best budget 3D printer, evaluate these factors alongside the initial price to avoid unexpected expenses.

Long-Term Costs and Maintenance of a 3D Printer

Material Costs and Availability

Understanding material costs is essential when planning for long-term 3D printing expenses. Materials like PLA and ABS are affordable and widely available, making them ideal for beginners. However, specialty materials such as titanium or carbon fiber can significantly increase your expenses due to their complex manufacturing processes. The availability of industrial-grade materials also plays a crucial role in determining your options. For instance, thermoplastics are more accessible, while high-performance composites may require specialized suppliers.

Tip: Opt for materials that align with your project needs and budget. This approach ensures you achieve quality results without overspending.

Replacement Parts and Repairs

Replacement parts are an inevitable aspect of 3D printer maintenance. Components like nozzles, belts, and build plates experience wear and tear over time. Minor repairs can add up, especially if your printer operates frequently. Regular inspections help you identify issues early, reducing the risk of costly breakdowns. Investing in durable parts and maintaining a stock of essential replacements ensures uninterrupted operation.

Regular Maintenance Tips

Routine maintenance enhances the lifespan and performance of your 3D printer. Cleaning the print bed and calibrating the axes regularly prevents common issues like misalignment and poor adhesion. Monitoring environmental factors, such as humidity and dust levels, also improves equipment efficiency. Adhering to recommended temperature settings minimizes clogs and ensures consistent extrusion.

Callout: Preventive maintenance reduces unexpected failures and can save up to 15% of your monthly operating expenses.

Choosing the right 3D printer involves several critical steps. You must identify your needs, understand printer types, evaluate features, set a realistic budget, and plan for long-term costs.

Tip: Research thoroughly and compare models to find the best fit for your goals. A well-chosen printer ensures maximum value and long-term satisfaction.

FAQ

What is the best 3D printer for beginners in 2025?

For beginners, entry-level FDM printers like the Sovol SV06 or Sovol SV06 ACE offer affordability, ease of use, and compatibility with basic materials like PLA.

Tip: Start with a printer that includes pre-assembled parts to simplify setup.

How do I choose the right material for my 3D printer?

Choose materials based on your project. PLA suits decorative items, ABS works for functional parts, and resin excels in high-detail models like jewelry or dental prototypes.

Are 3D printers expensive to maintain?

Maintenance costs depend on usage. Regular expenses include materials, replacement parts (e.g., nozzles), and occasional repairs. Opt for models with affordable consumables to minimize long-term costs.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.