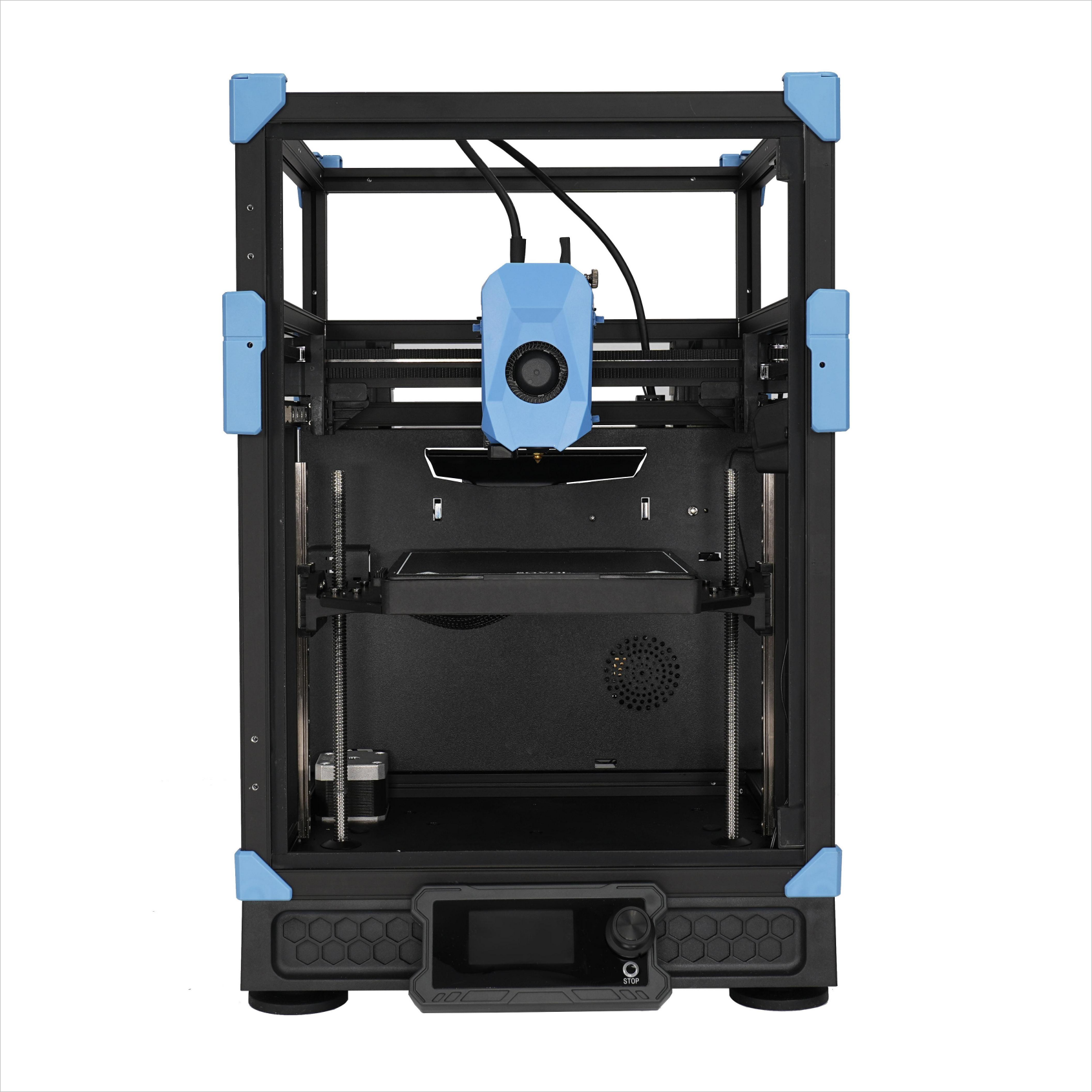

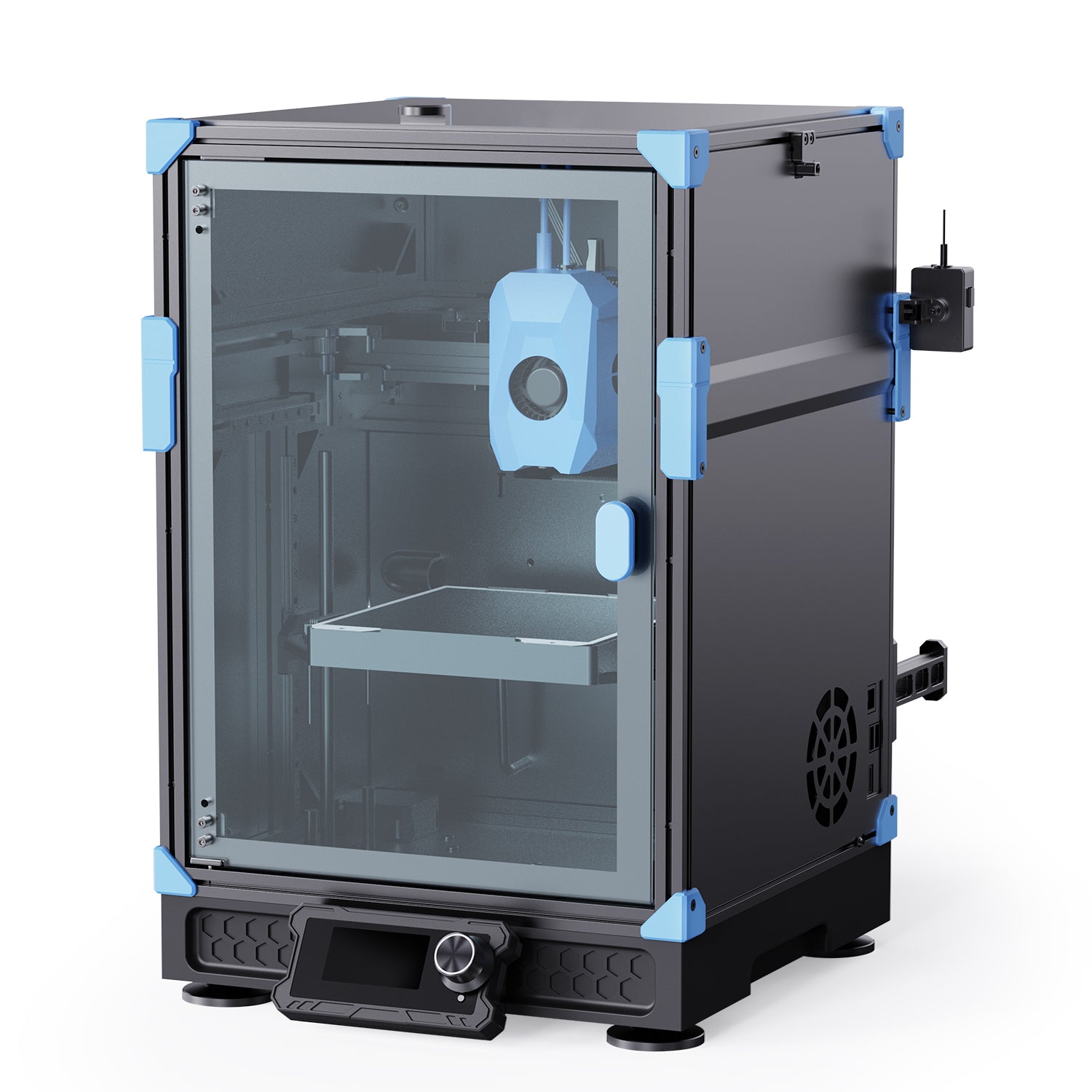

Sovol Zero 3D Printer

- The World's Fastest CoreXY 3D Printer

- Faster & More Accurate & Easier to Use

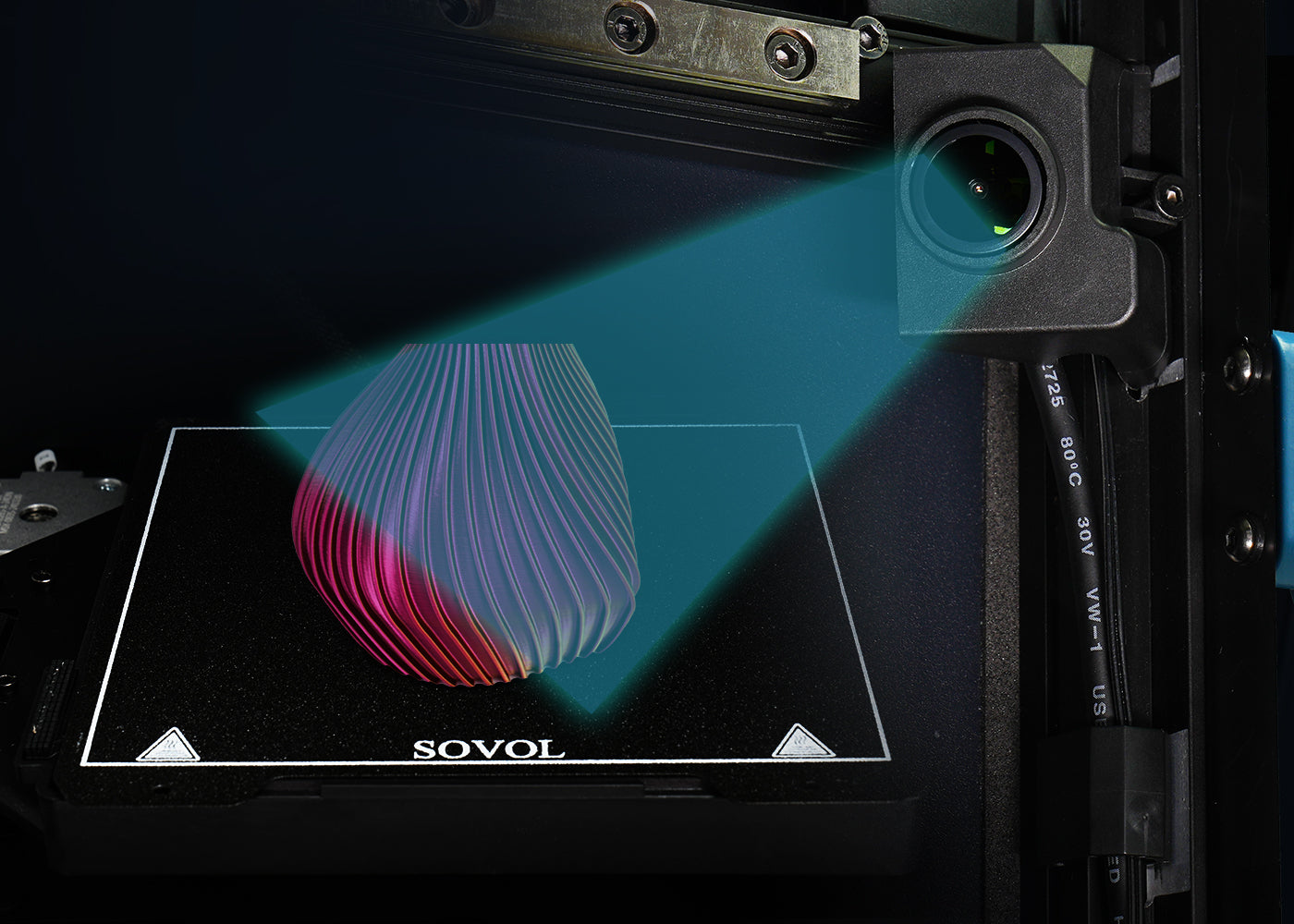

- Auto-Leveling: Eddy Scanning & Pressure Sensing

- XYZ Full Linear Rails

- Build Volume: 152.4*152.4*152.5mm³

- Nozzle Temperature: ≤350℃ (662℉)

- Hot bed Temperature: ≤120℃ (248℉)

- Ready to Use with Complete Machine Delivery

1200mm/s

Unleash your creativity with the unprecedented 1200mm/s printing speed! Experience the next level of 3D printing with Sovol Zero, designed for blazing-fast performance, precision, and reliability. Push the limits of your imagination with unmatched speed and efficiency!

Ultimate CoreXY Kinematics, Ultimate Speed

With a more compact design, fewer moving parts, faster acceleration, and reduced vibration, CoreXY delivers high-speed, precise printing like never before.

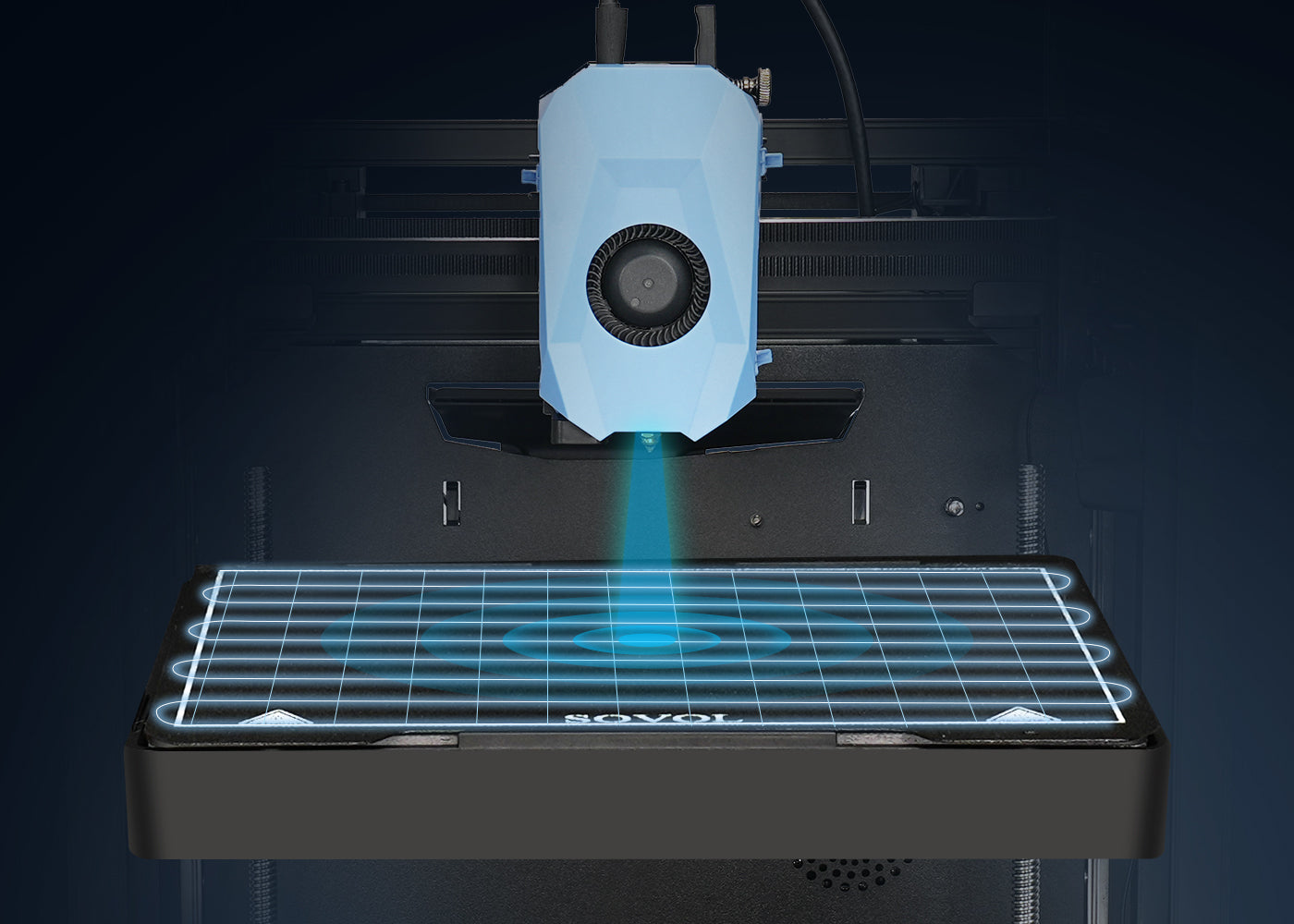

Next-Gen 3.0 Auto-Leveling

The all-new 3.0 auto-leveling system combines eddy current scanning with pressure sensing for unparalleled accuracy. The eddy current sensor rapidly maps the Z-axis compensation grid without physical contact, using magnetic induction for faster data acquisition. Then, the pressure sensor fine-tunes the precise touchpoint location, ensuring exceptional leveling precision while minimizing errors.

High-Temp Nozzle, Unlimited Potential

Reach up to 350°C with ease—perfectly handling PA, PC, and other high-performance materials for your most ambitious projects.

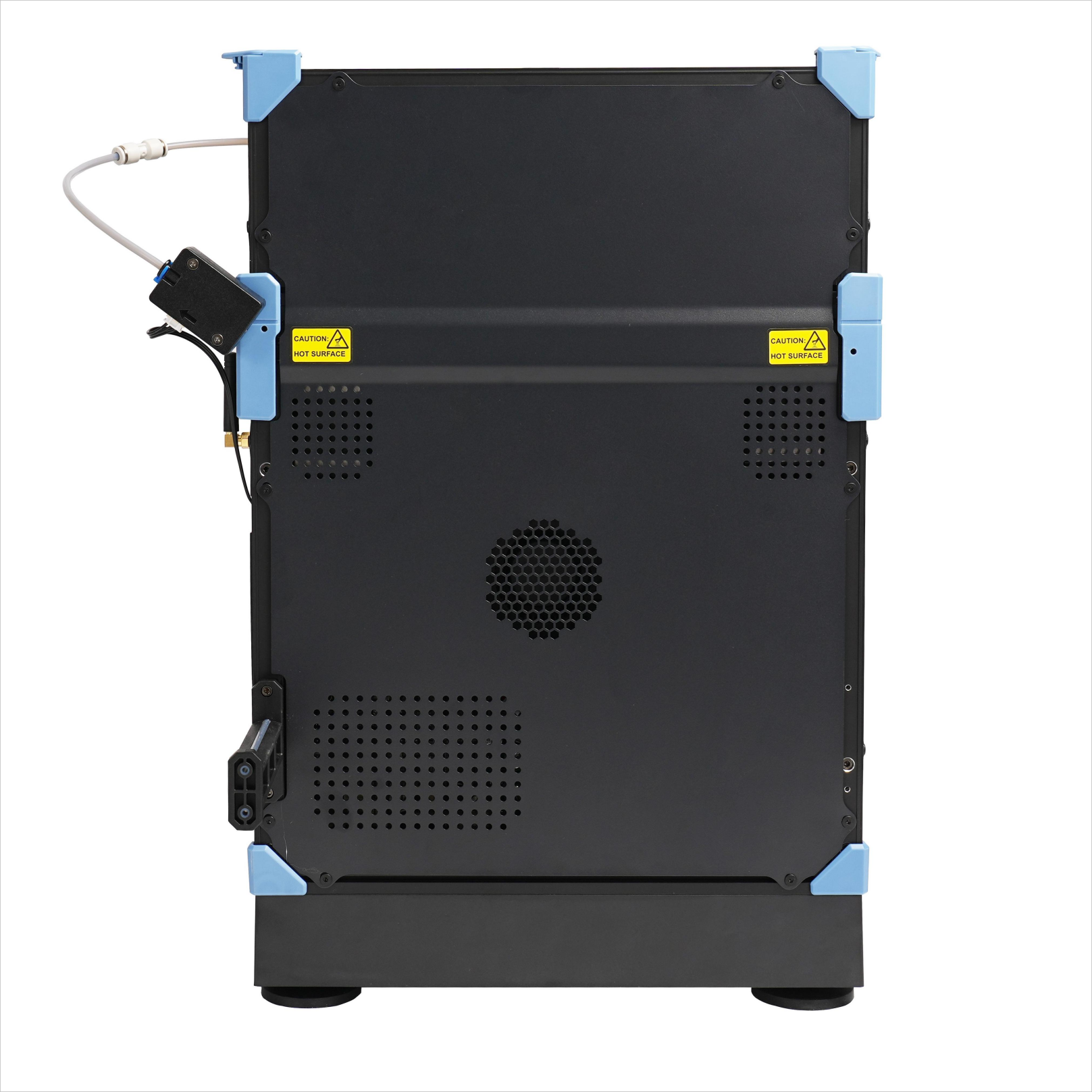

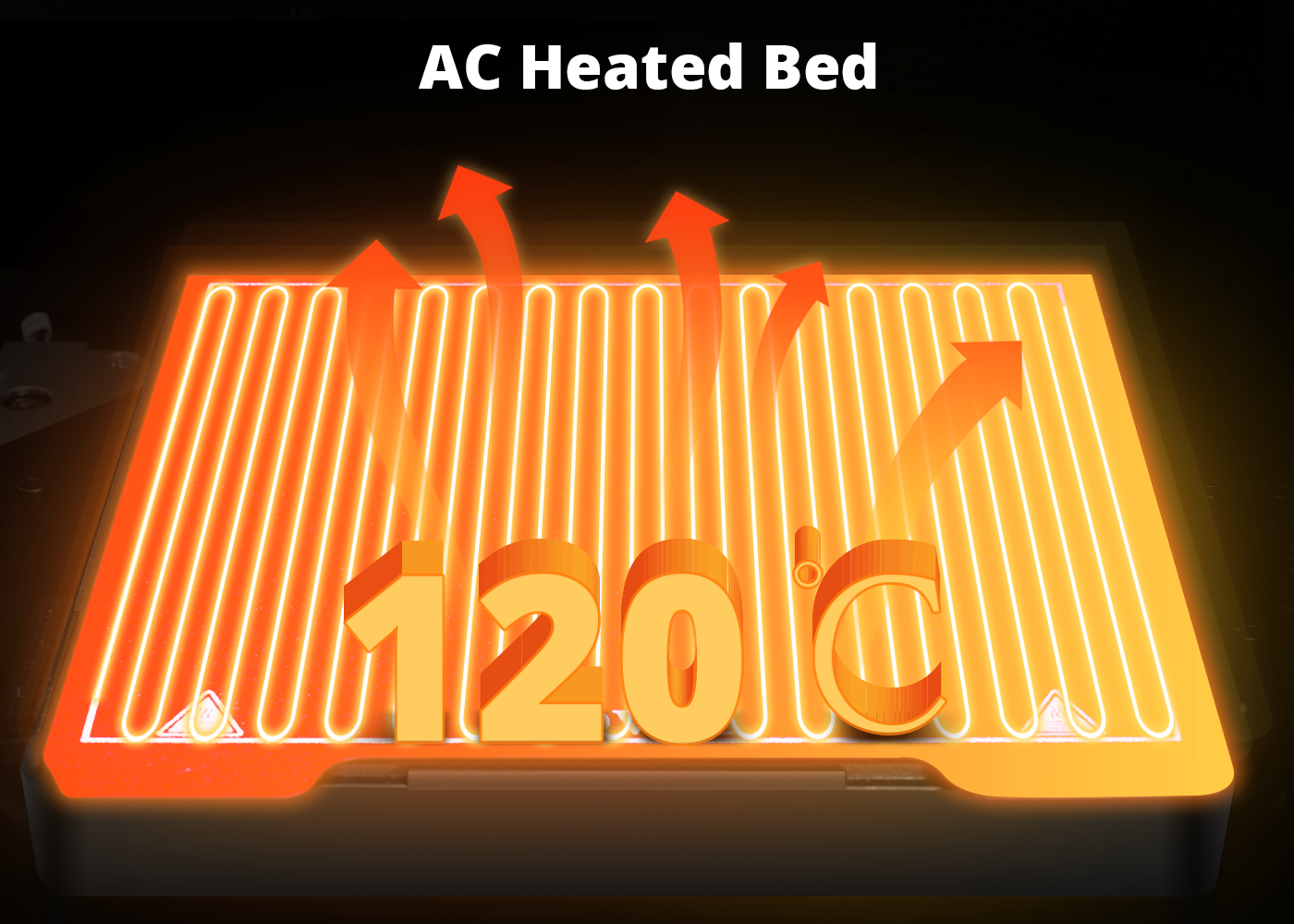

AC Heated Bed

Zero utilizes an AC heated bed, reaching a maximum temperature of 120°C. AC heating enables faster heat-up, reducing preparation time and ensuring stable bed temperatures during long prints. A high-temperature heated bed is essential for successfully printing high-temperature filaments. It also includes an overheating protection feature for added safety.

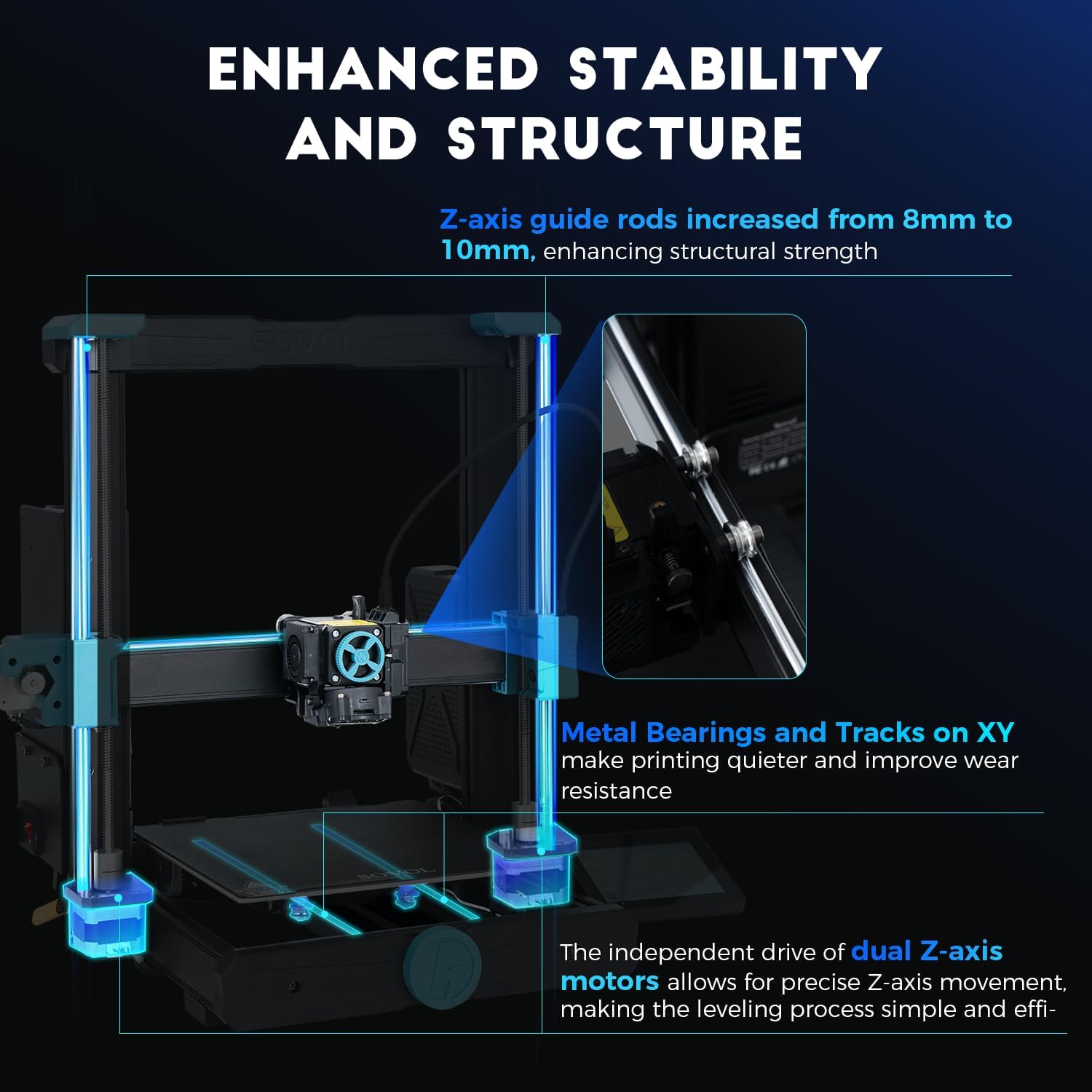

XYZ Full Linear Rails

Linear rails ensure smoother motion and superior control, enhancing print quality and reliability by minimizing artifacts. With greater rigidity and corrosion resistance, they offer extended durability for long-term performance.

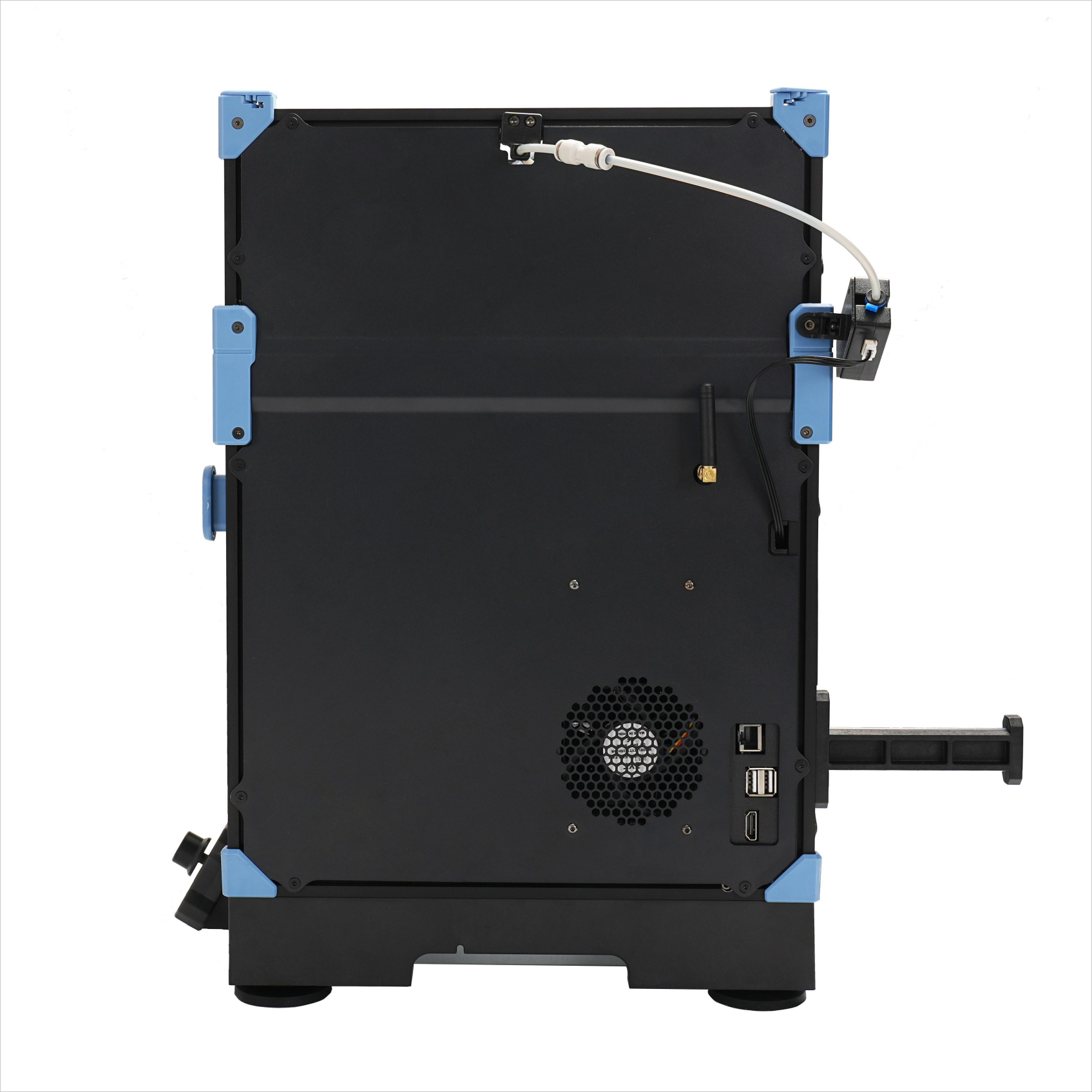

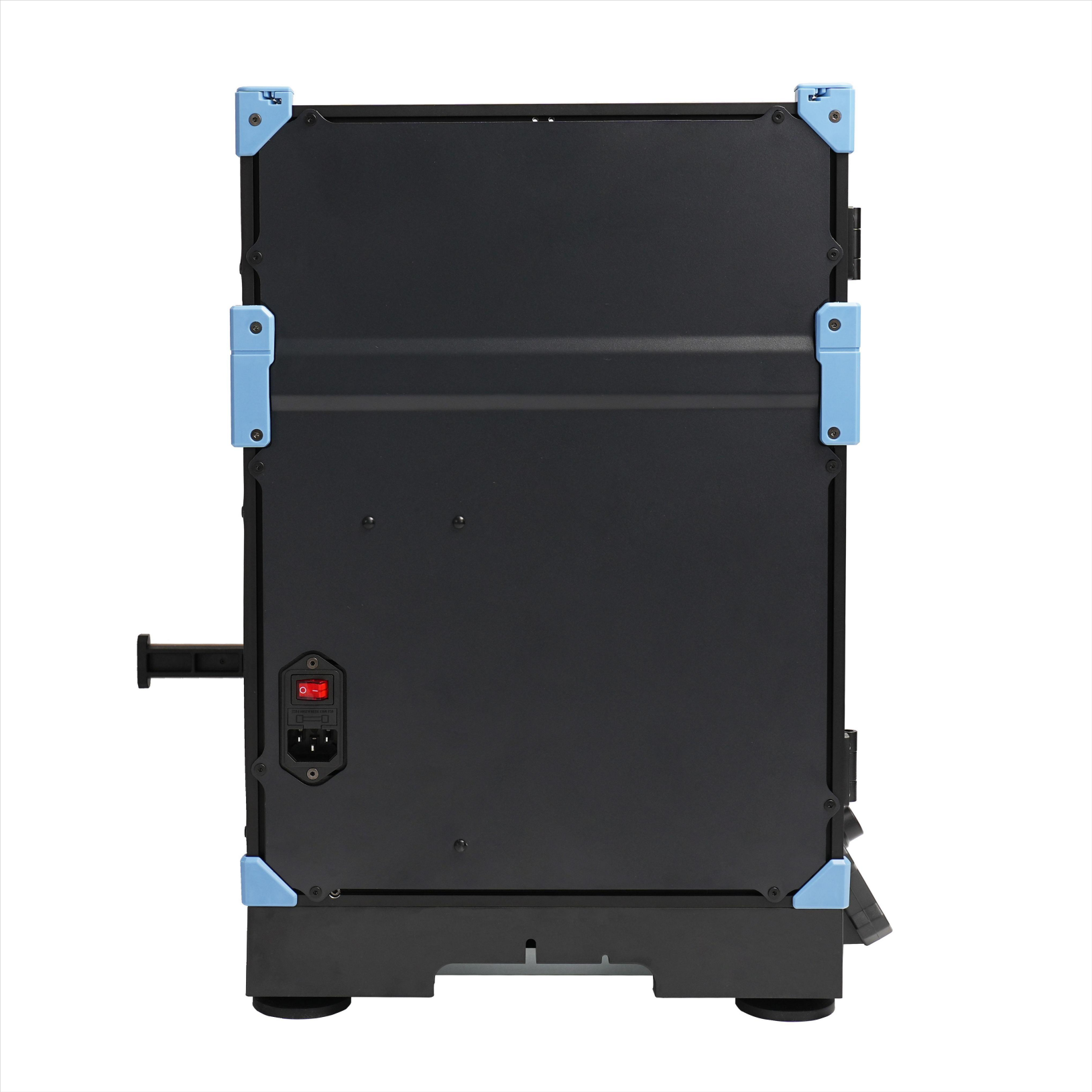

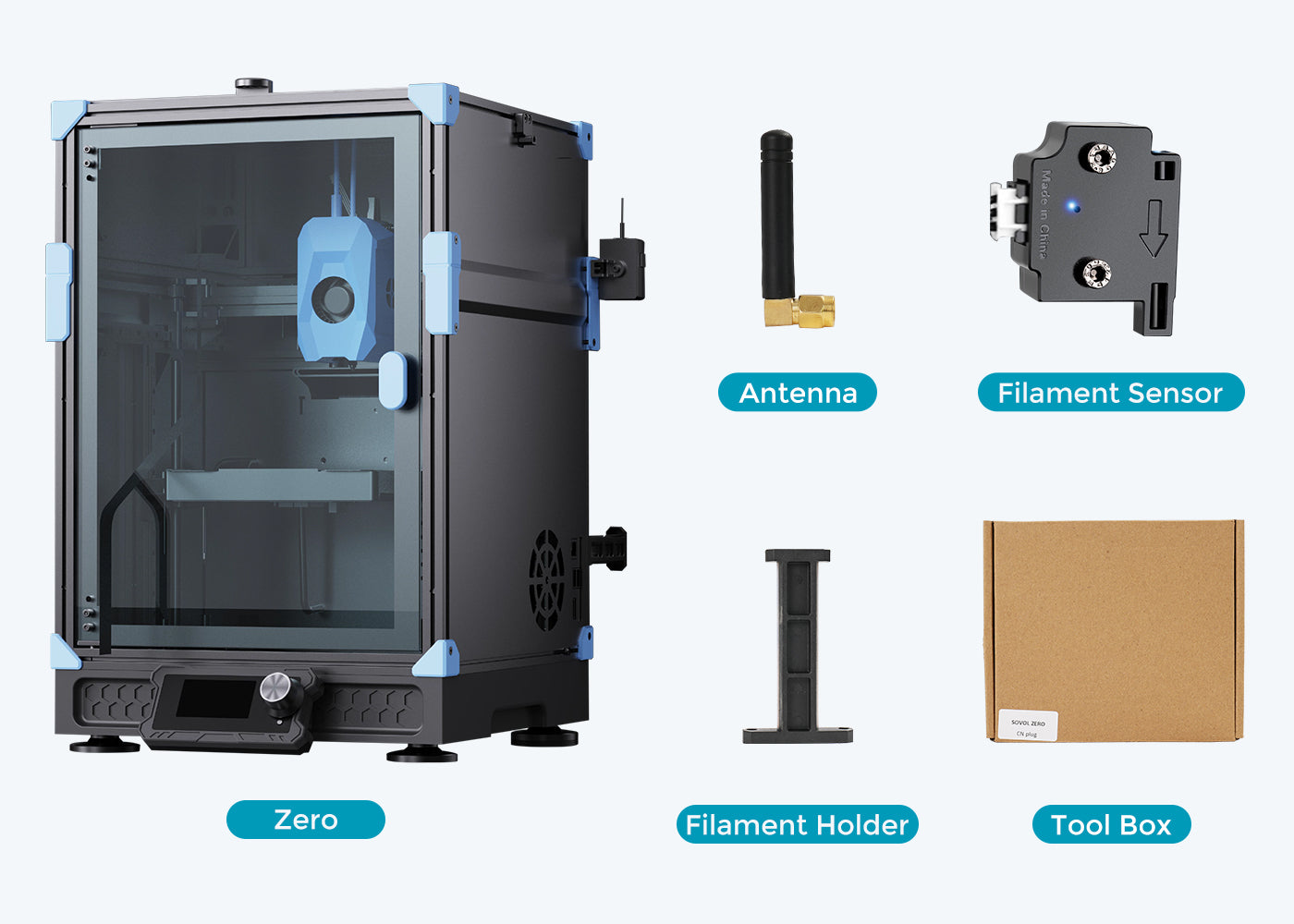

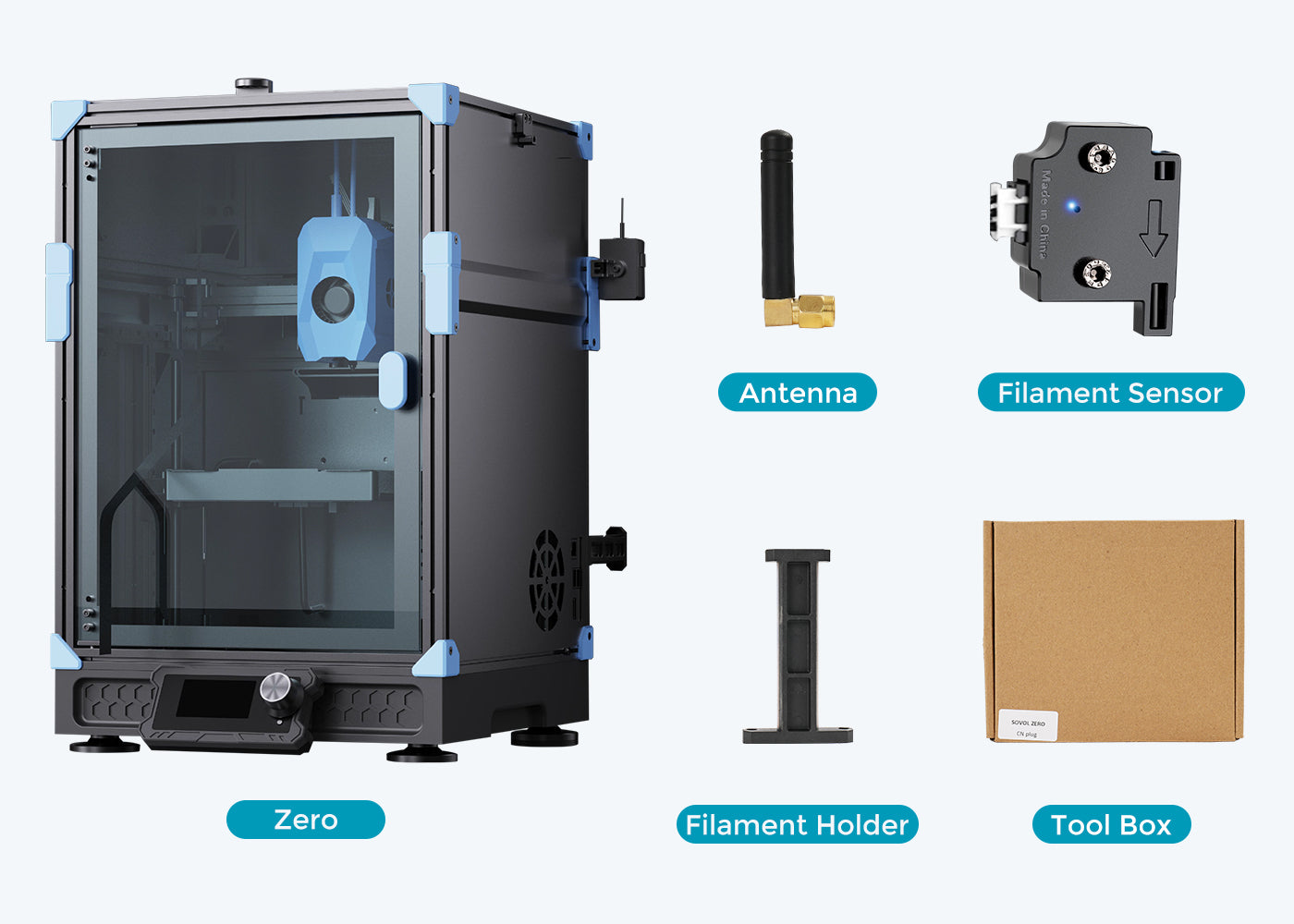

Shipped as a complete unit, no extensive assembly required. Simply install the external antenna, screen, and filament sensor to get started.

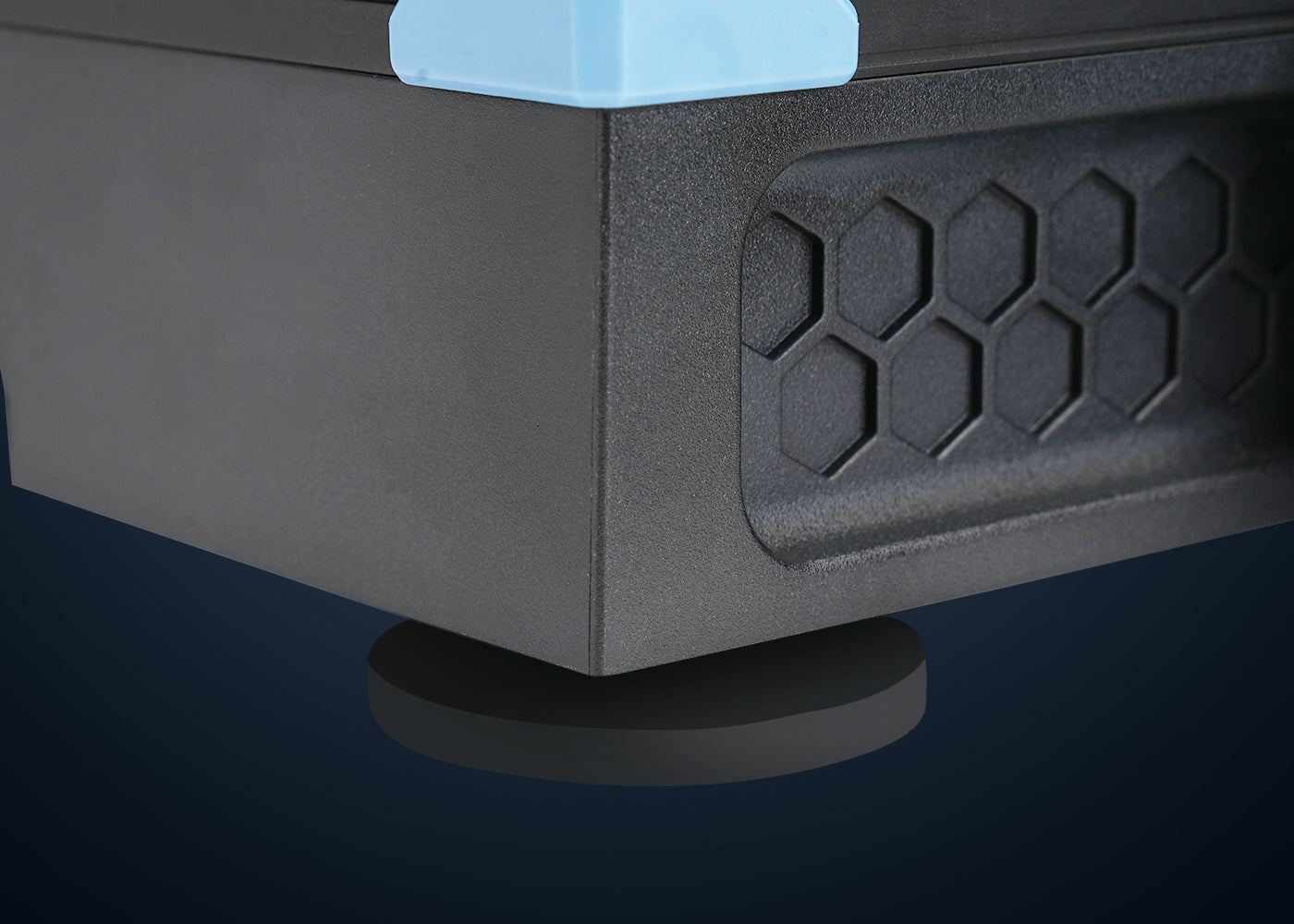

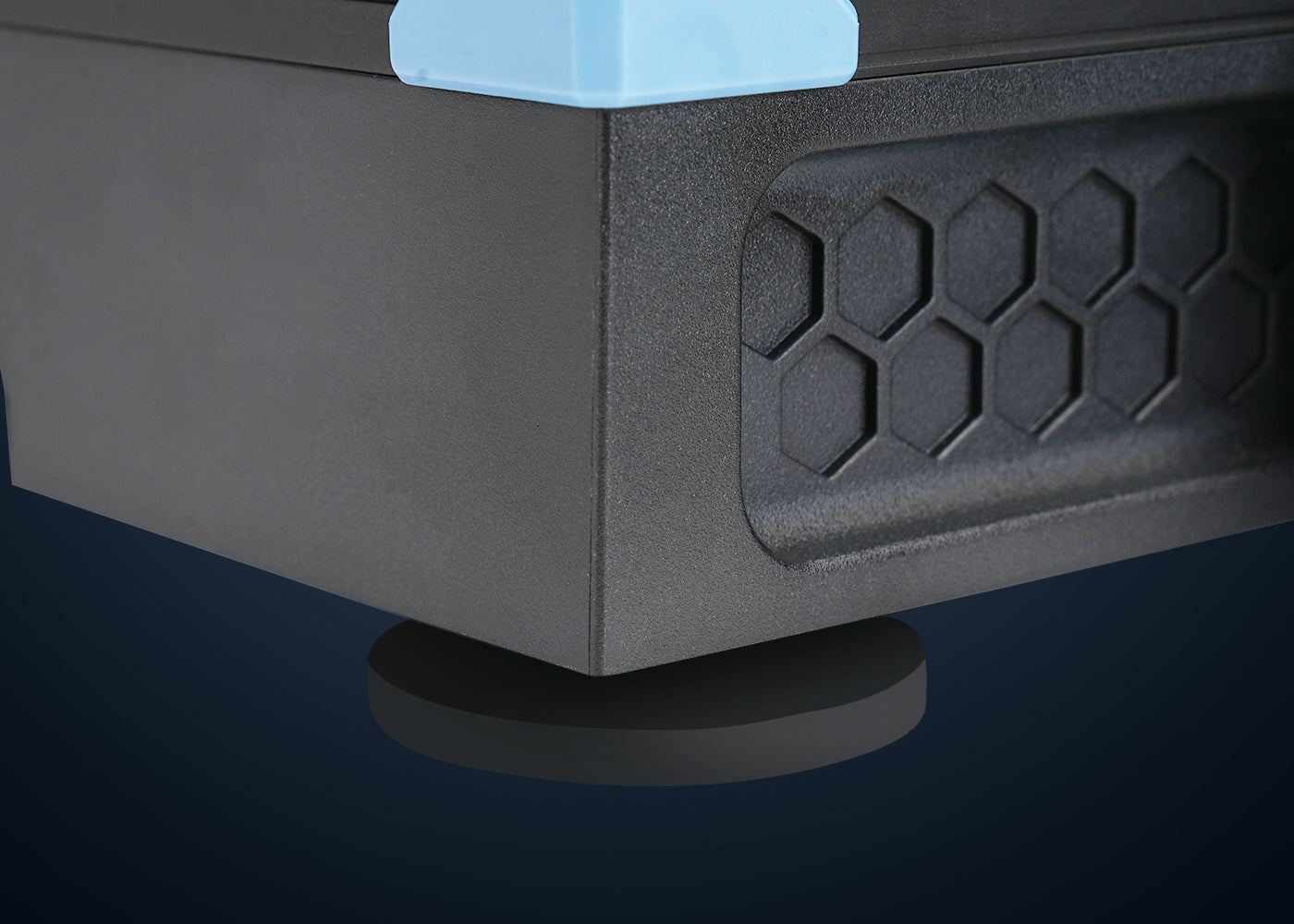

The damping pad effectively absorbs vibrations generated during the high-speed operation of the 3D printer, enhancing the device's stability and user experience. It ensures a smoother and more stable fast printing process, thereby improving print quality.

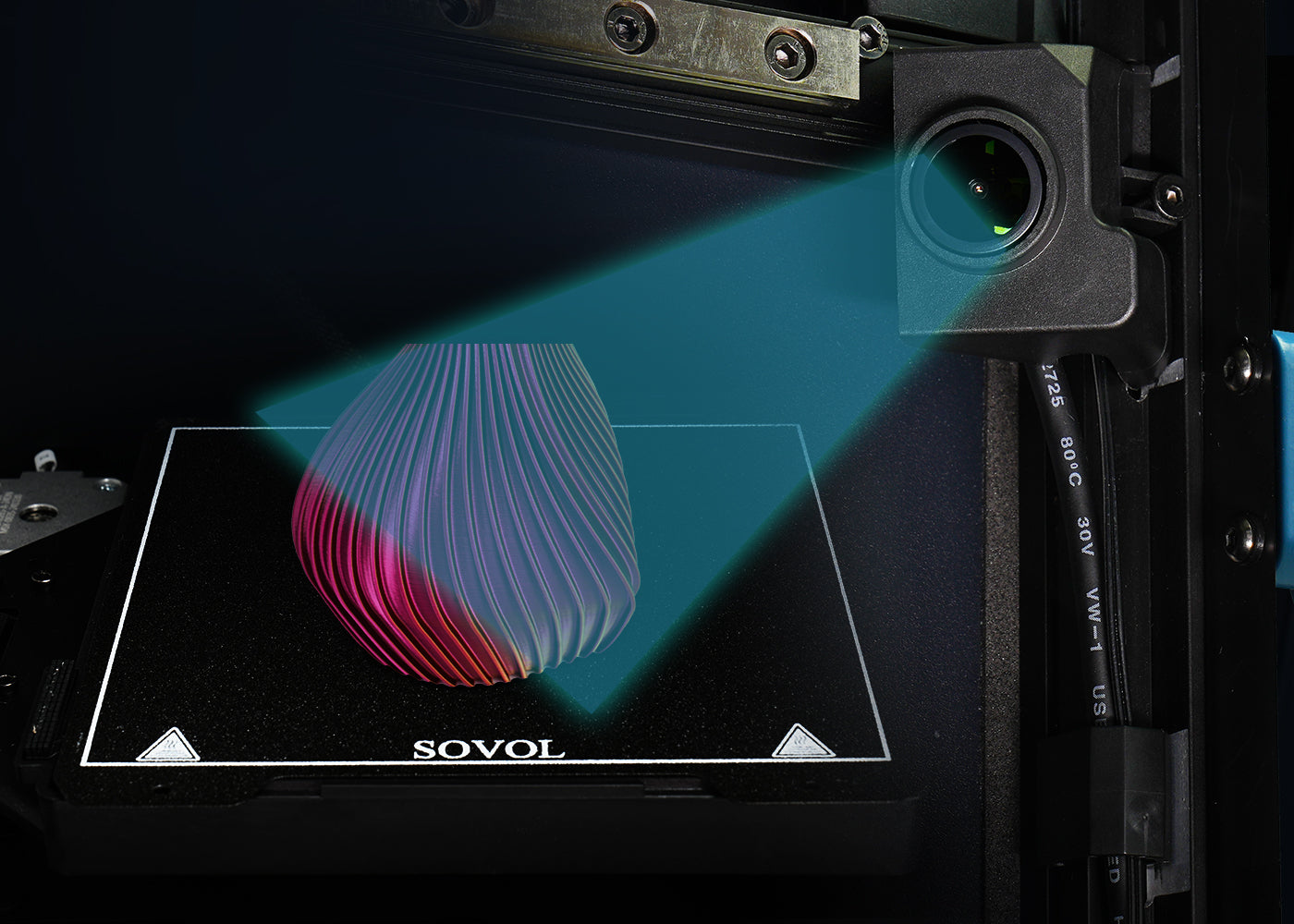

The camera provides real-time monitoring and detection of the printing process (in conjunction with Obico). It also records the entire printing journey, offering time-lapse footage and providing convenience and insights into the printing experience.

By utilizing eddy current scanning and pressure-sensing touch points for automatic bed calibration, achieving a perfect first layer becomes effortless, requiring no action on your part.

With higher hotend and heated bed temperatures, the 3D printer supports a wider range of advanced and challenging filaments, catering to more applications and diverse printing needs.

Shipped as a complete unit, no extensive assembly required. Simply install the external antenna, screen, and filament sensor to get started.

The damping pad effectively absorbs vibrations generated during the high-speed operation of the 3D printer, enhancing the device's stability and user experience. It ensures a smoother and more stable fast printing process, thereby improving print quality.

The camera provides real-time monitoring and detection of the printing process (in conjunction with Obico). It also records the entire printing journey, offering time-lapse footage and providing convenience and insights into the printing experience.

By utilizing eddy current scanning and pressure-sensing touch points for automatic bed calibration, achieving a perfect first layer becomes effortless, requiring no action on your part.

With higher hotend and heated bed temperatures, the 3D printer supports a wider range of advanced and challenging filaments, catering to more applications and diverse printing needs.

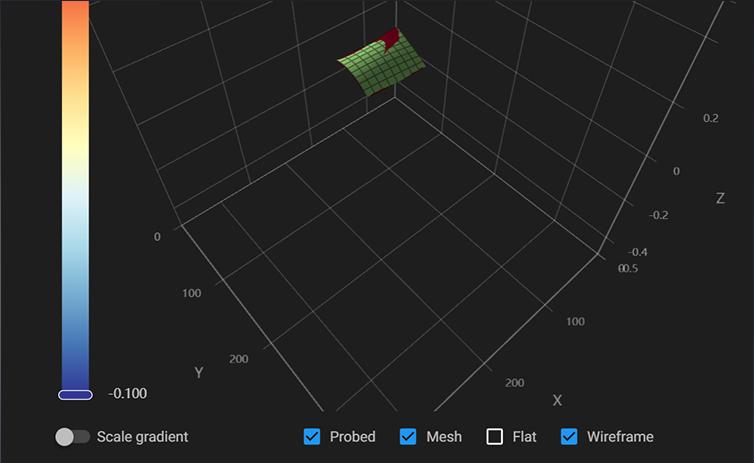

Adaptive Area Detection

Adaptive area detection compensates for leveling based on the downward projection of the print model, effectively reducing leveling preparation time. By detecting the model's geometry, the extrusion volume is optimized to improve accuracy in detail areas.

Pressure Advance

Pressure Advance optimizes extruder control by compensating for extrusion lag. It adjusts flow before movement changes (corners or acceleration/deceleration), ensuring precise extrusion and minimizing over- or under-extrusion, significantly improving print accuracy and speed.

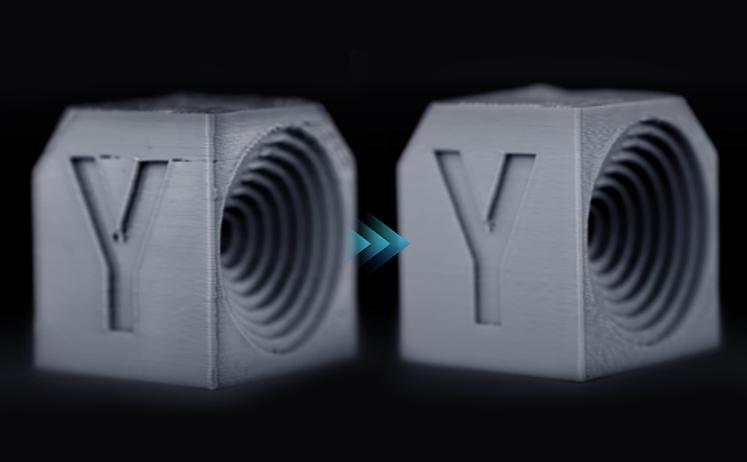

Input Shaping

Input Shaping technology mathematically adjusts the printer’s acceleration commands to compensate for mechanical resonance caused by rapid movements, reducing ringing/ghosting artifacts during printing. This allows for higher printing speeds while maintaining superior print quality.

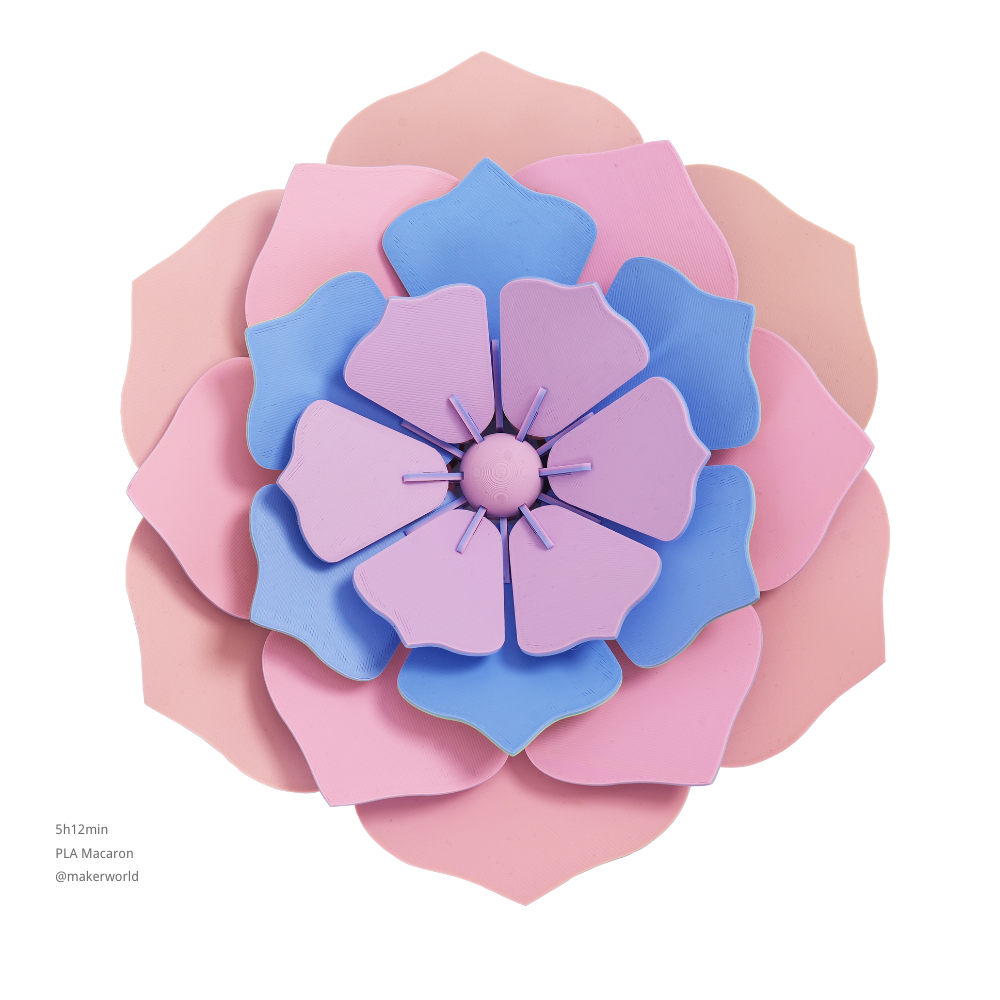

Works Printed By Zero

FAQs

Does Sovol Zero include Enclosure Box?

Yes, Zero will be shipped as a complete machine, including the enclosure and glass door.

What slicing software is Zero compatible with?

Any slicer that can export G-Code, such as SuperSlicer.

What's Included in The Package?

As you can see, it includes the complete printer installed (Filament holder, screen, signal receiver, filament sensor which takes a minute to assemble), 0.4mm*2 nozzles, and a roll of filament for testing the printer.

Will the Zero’s nozzle fall off and damage the heated bed?

No, the Zero’s nozzle is securely connected to the hotend with a threaded design, ensuring it won’t fall off and cause damage to the heated bed.

Is Zero's eddy current sensor compatible with SV08?

No, the good news is that we are developing an eddy current sensor that is compatible with SV08.

Product specification

152.4*152.4*152.5mm³

1200mm/s

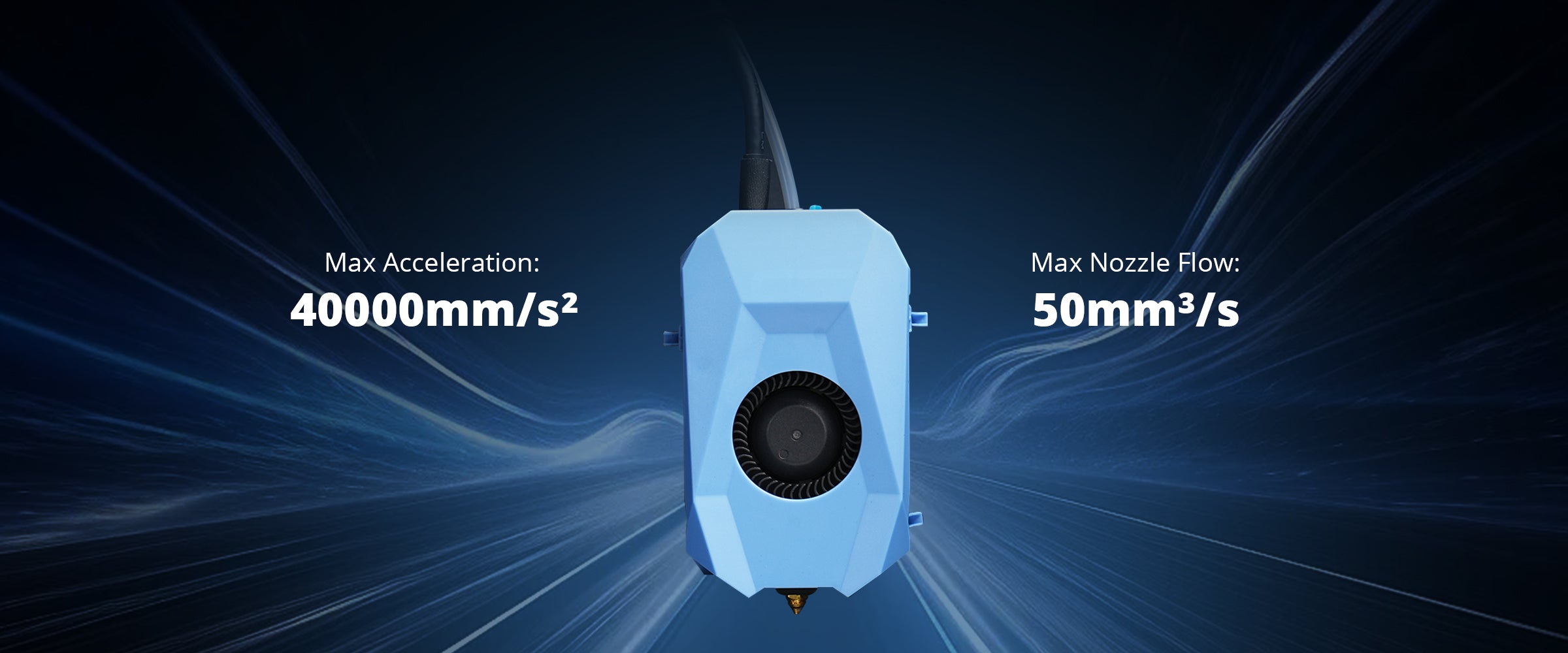

40000mm/s²

≤50mm³/s

Ceramic Heating Plate

Inductive sensor + force sensor

Ethernet, Wi-Fi: 2.4 GHz (WPA2 only, WPA3 not supported)

Brass: 0.4mm (Include), 0.2mm 0.6mm, 0.8mm. 1.0mm

Hardened steel: 0.4mm (Include), 0.2mm, 0.6mm, 0.8mm. 1.0mm

≤350℃(662℉)

≤120℃(248℉)

1.75mm

Windows, Mac

345*420*475mm

150W/24V

Double-Sided PEI Steel Plate

Yes

Yes

PLA, PETG, TPU, PETG-CF, ABS, ASA, PA, PC

Planetary gear extruder

Yes

OrcaSlicer

G-code

64-bit

Yes

H616

1GB

8GB(EMMC)