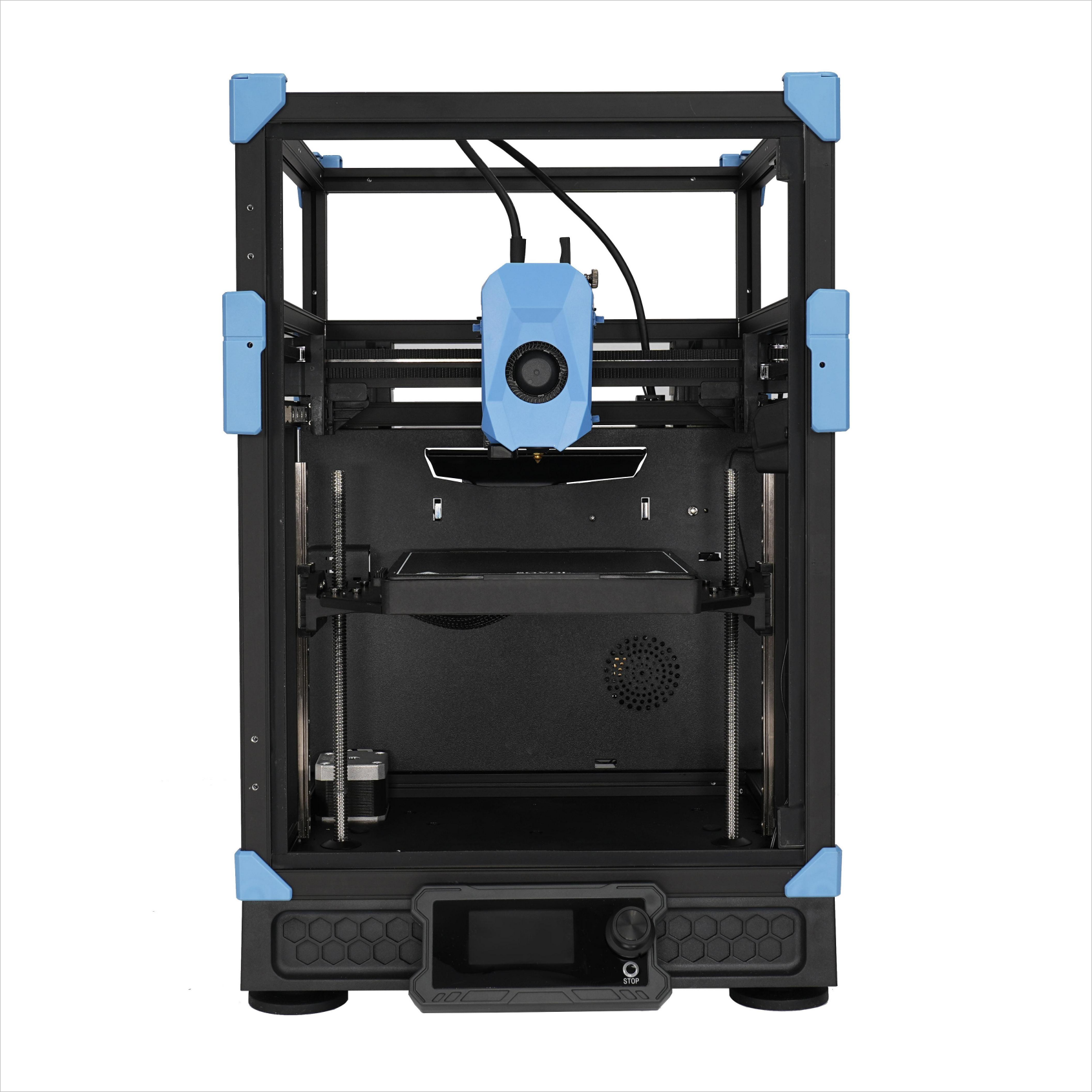

CoreXY 3D printers revolutionize your projects by combining speed, precision, and efficiency. They excel in delivering consistent print quality through advanced mechanics. For instance, users often analyze ghosting and ringing artifacts to ensure optimal results. Tools like laser levels and vibration analysis apps measure deflection and stability, demonstrating the precision you can achieve with these machines. Furthermore, models like the Sovol SV08 offer impressive efficiency, reaching speeds of up to 700mm/s and acceleration of 40,000mm/s². These attributes, paired with a compact design, make CoreXY printers indispensable for achieving reliable and high-quality outcomes.

Key Takeaways

- CoreXY 3D printers are fast and accurate, printing up to 700mm/s.

- Their special belt system lowers weight, making movements quicker and steadier.

- Taking care of the printer, like tightening belts, keeps it working well.

- CoreXY printers are small but can still print big objects, great for tight spaces.

- Buying a CoreXY printer saves money over time because it lasts long and works efficiently.

Unique Features of CoreXY 3D Printers

CoreXY Motion System and Mechanics

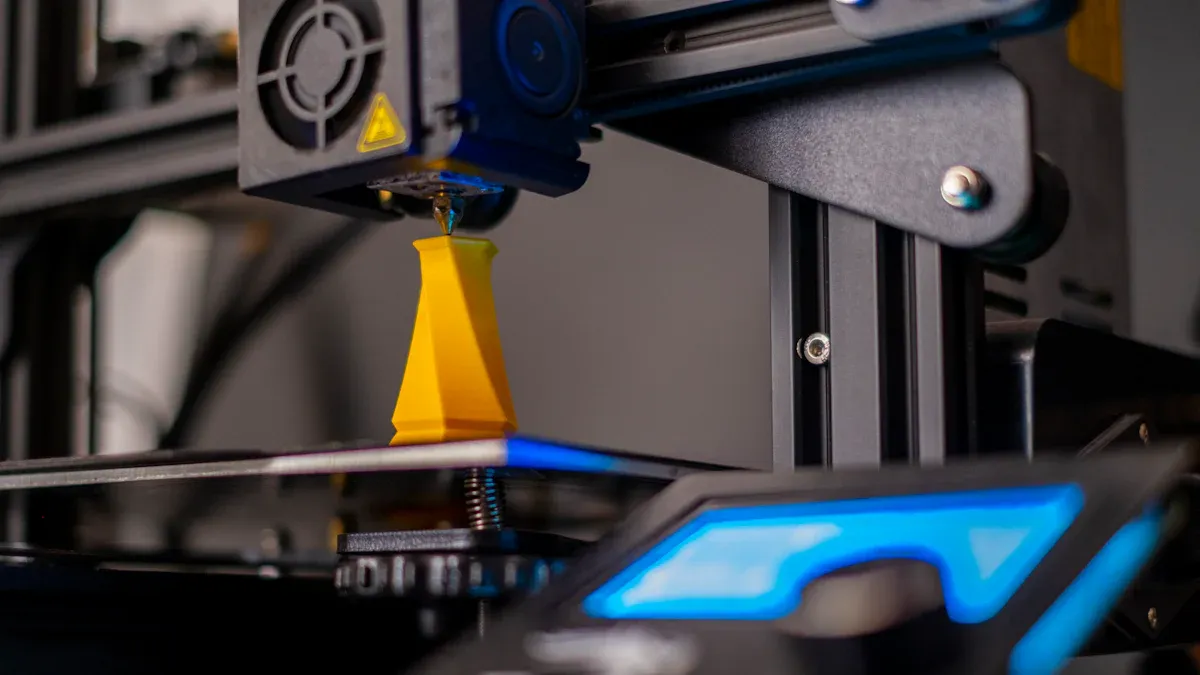

The core of a CoreXY 3D printer lies in its innovative motion system. Unlike traditional Cartesian setups, CoreXY employs a unique belt-driven mechanism. This design uses two motors working in tandem to control the X and Y axes. The belts move in a coordinated manner, allowing the print head to glide smoothly across the build platform. This system minimizes the weight of moving parts, reducing inertia and enabling faster movements without compromising precision.

CoreXY's mechanics also enhance stability. The fixed bed design ensures that the Z-axis remains stationary during printing, which eliminates wobbling and improves layer alignment. This feature is particularly beneficial when creating exhibition-quality models or working with larger build volumes. Additionally, the system's simplicity reduces wear and tear, making it a reliable choice for long-term use.

Advantages and Disadvantages of CoreXY Design

CoreXY printers offer several advantages that set them apart from other 3D printing technology. Their lightweight motion system enables higher speeds and accelerations, resulting in faster print times. The design also supports larger build volumes without requiring a bulky frame, making it ideal for space-conscious users. Furthermore, the reduced moving mass contributes to consistent precision, ensuring high-quality results.

However, the CoreXY design has its challenges. Proper belt tensioning is crucial for optimal performance, and misalignment can lead to print defects. The setup process may require more attention compared to simpler printer designs. Despite these drawbacks, the benefits of CoreXY 3D printers often outweigh the disadvantages, especially for users seeking speed, accuracy, and reliability.

Tip: Regular maintenance, such as checking belt tension and alignment, can help you maximize the performance of your CoreXY printer.

Benefits of CoreXY 3D Printers

Faster Print Quality and Speed

CoreXY 3D printers excel in delivering high-speed printing without sacrificing quality. Their lightweight motion system minimizes inertia, allowing the print head to move swiftly across the build platform. This design ensures that you achieve faster print quality and speed, even for complex models. For instance, the belt-driven mechanism enables rapid accelerations, making it ideal for time-sensitive projects. Whether you're prototyping or producing functional parts, CoreXY printers help you meet tight deadlines with ease.

Additionally, the synchronized movement of the belts ensures smooth transitions between layers. This feature reduces the risk of defects like ghosting or ringing, which can occur at high speeds. By optimizing print speed and accuracy, CoreXY printers provide a reliable solution for users who demand efficiency and precision.

Consistent Precision and Accuracy

CoreXY 3D printers are renowned for their consistent precision. The innovative motion system eliminates unnecessary vibrations, ensuring that each layer aligns perfectly. This level of accuracy is crucial when working on intricate designs or detailed models. You can trust CoreXY printers to maintain the integrity of your prints, even during extended operations.

The fixed bed design further enhances precision by keeping the Z-axis stationary. This stability prevents layer shifts and ensures uniformity throughout the print. Whether you're creating prototypes or artistic pieces, CoreXY printers deliver results that meet professional standards. Regular maintenance, such as checking belt tension, can help you sustain this level of performance over time.

Compact Design for Space Efficiency

CoreXY printers offer a compact design that maximizes space efficiency. Unlike traditional 3D printers, they achieve larger build volumes without requiring a bulky frame. This makes them an excellent choice for users with limited workspace. You can easily integrate a CoreXY 3D printer into your setup without compromising on functionality.

The streamlined design also simplifies transportation and storage. Whether you're a hobbyist or a professional, the space-saving nature of CoreXY printers allows you to focus on your projects without worrying about logistical constraints. Their compact footprint, combined with high-speed printing capabilities, makes them a versatile addition to any workspace.

Enhanced Durability and Reliability

CoreXY 3D printers are built to last, offering exceptional durability and reliability for your projects. Their robust design ensures that you can rely on them for consistent performance over extended periods. Unlike other printer types, CoreXY systems minimize wear and tear by reducing the number of moving parts. This feature not only extends the lifespan of the machine but also reduces the need for frequent repairs.

The belt-driven motion system plays a significant role in enhancing reliability. High-quality belts and pulleys ensure smooth and precise movements, even during high-speed operations. You can trust your CoreXY printer to maintain accuracy without compromising on durability. Regular maintenance, such as cleaning and inspecting the belts, further boosts the machine's longevity.

Pro Tip: Use high-quality components and lubricants to keep your CoreXY printer running smoothly for years.

Another advantage of CoreXY printers is their ability to handle demanding workloads. Whether you're printing intricate designs or large-scale models, these machines deliver consistent results. The fixed bed design eliminates the risk of wobbling, ensuring that your prints remain stable and precise. This reliability makes CoreXY printers an excellent choice for both hobbyists and professionals.

Additionally, the compact and lightweight frame of a CoreXY printer contributes to its durability. The reduced strain on the structure prevents mechanical failures, even during prolonged use. You can depend on these printers to perform reliably, no matter the complexity of your projects. With proper care, a CoreXY 3D printer becomes a long-term investment that simplifies your workflow and enhances productivity.

How CoreXY 3D Printers Improve Workflow

Simplified Setup and Maintenance

CoreXY 3D printers are designed with a user-friendly interface that simplifies both setup and maintenance. You can quickly assemble these printers due to their modular components and intuitive design. Unlike traditional 3D printers, CoreXY models often come with pre-calibrated systems, reducing the time you spend on initial adjustments. This streamlined setup process allows you to focus on your projects rather than troubleshooting hardware.

Maintenance is equally straightforward. The belt-driven motion system requires minimal upkeep, as it reduces wear and tear on moving parts. Regular tasks, such as checking belt tension and cleaning the build platform, are easy to perform. These features ensure that your CoreXY printer remains operational with minimal downtime, making it an excellent choice for fast prototyping and long-term use.

Long-Term Cost-Effectiveness

Investing in a CoreXY 3D printer offers significant long-term cost savings. The durable design minimizes the need for frequent repairs, reducing maintenance expenses. Additionally, the belt-driven system ensures consistent performance, which translates to fewer failed prints and less wasted material.

CoreXY printers also support a wide range of affordable filaments, giving you more flexibility in material selection. Their energy-efficient operation further lowers running costs, making them an economical choice for both hobbyists and professionals. Over time, these savings add up, making CoreXY printers a cost-effective solution for your 3D printing needs.

Tip: Regular maintenance, such as cleaning and lubricating the belts, can extend the lifespan of your printer and maximize your investment.

CoreXY 3D printers deliver unmatched speed, precision, and reliability, making them essential for simplifying your projects. Their advanced kinematics and motion control systems ensure consistent performance. For example, these printers achieve speeds of up to 700 mm/s and accelerations of 40,000 mm/s². The table below highlights their impressive specifications:

| Feature | Specification |

|---|---|

| Maximum Print Speed | 700 mm/s |

| Maximum Acceleration | 40,000 mm/s² |

| Motion Control | CoreXY kinematics |

| Linear Motion System | Linear rails for all 7 axes |

| Extruder Control | Pressure Advance |

| Compensation for Resonance | Input Shaping technology |

Whether you're a hobbyist or a professional, investing in a CoreXY printer ensures superior results and streamlined workflows.

FAQ

What makes CoreXY printers different from Cartesian printers?

CoreXY printers use a belt-driven motion system, while Cartesian printers rely on independent motor movements for each axis. This design reduces moving mass, enabling faster speeds and higher precision. CoreXY printers also offer better space efficiency and stability, making them ideal for professional and hobbyist use.

Are CoreXY printers suitable for beginners?

Yes, CoreXY printers are beginner-friendly. Many models come with pre-assembled components and intuitive interfaces, simplifying the setup process. Regular maintenance, such as checking belt tension, is straightforward. Beginners can quickly learn to operate these printers while enjoying their speed and precision.

Can CoreXY printers handle flexible or high-temperature materials?

CoreXY printers support a wide range of materials, including flexible and high-temperature filaments. Their robust design and advanced extruder systems ensure consistent performance with challenging materials. Always check your printer's specifications to confirm compatibility with specific filament types.

How do I maintain a CoreXY 3D printer?

Regular maintenance includes checking belt tension, cleaning the build platform, and inspecting moving parts for wear. Lubricate rails and pulleys as needed to ensure smooth operation. Following the manufacturer's guidelines helps extend the printer's lifespan and maintain optimal performance.

Are CoreXY printers cost-effective in the long run?

CoreXY printers offer long-term cost savings due to their durable design and efficient operation. They reduce material waste by minimizing print errors and support affordable filament options. Their energy-efficient systems also lower operational costs, making them a smart investment for consistent, high-quality printing.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.