Introduction

In today’s fast-paced design-build evolution of Fused Deposition Modeling or FDM3D Printers from; Cartesian, Delta, Polar& Scara.

A lot of makers, hobbyist or people who are just fascinated by 3D Printers can give out their ideas and even debate on which is better or best amongst the design available in the market.

But in this article, we are going to focus on the core part of the 3D Printer which is the “EXTRUDER”.We’ll discuss it in the most detailed way we can.

Think of your EXTRUDER as the heart of the Printer, wherein you also have the brain (Electronics) and the body(Machine)just to complete the analogy to human anatomy.

Technically, EXTRUDER is responsible for any melting/processing of filament to complete Fused Deposition Principle, melted plastic fuses on top of each other from time to time until it completes your sliced desired print out completion.

This is a very critical part of your printer; a small error on this part will definitely disrupt the whole printing process or might have a great effect on your print output.

Let’s discover more about the types of EXTRUDER setup particularly “DIRECT DRIVE AND BOWDEN TYPE”.

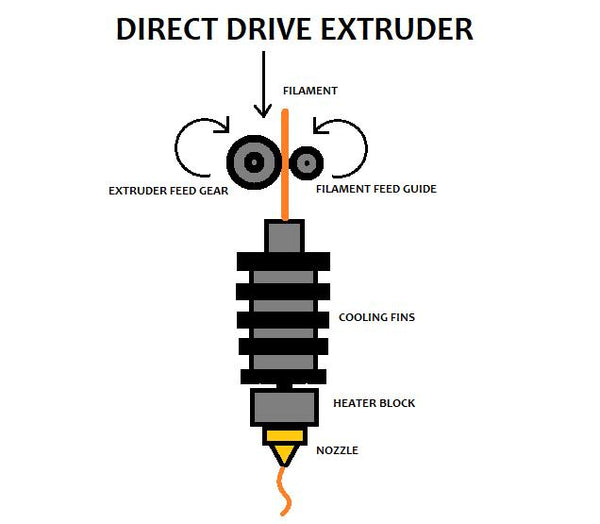

Direct Drive Extruder

is a setup wherein the extruder motor is placed closest possible to the EXTRUDER setup making filament feeding direct to the cooling fin, heater block, down to the nozzle. See figure below.

The image above shows how direct drive extruder works. As stated, Extruder feed gear attached from the extruder is placed closest to the cooling fin.

It also shows how extruder feed gear and filament feed guide rotates in order to feed the filament directly to the cooling fins.

Take note that making the extruder feed gear together with the filament feed guide will even be more advantageous than a farther placed extruder feed gear and filament feed guide.

Moving on to the second most common extruder setup is the Bowden extruder setup.

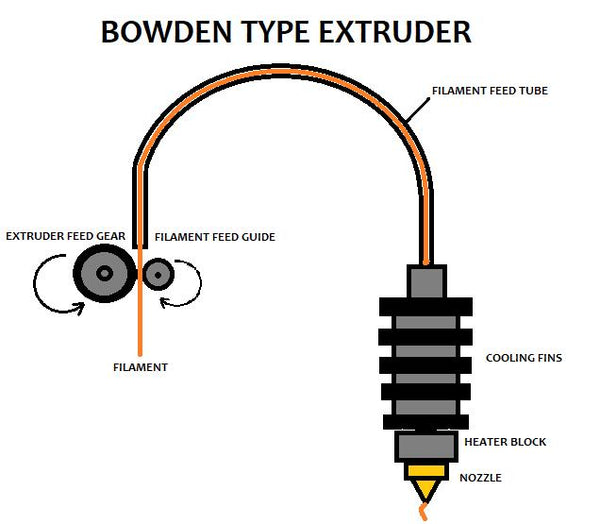

BOWDEN EXTRUDER

It is a setup wherein the extruder motor is placed far from the EXTRUDER. The filament is being fed in the extruder via tubes that fits the filament diameter.

Image below shows how Bowden extruder setup works.

The image above shows a typical type of extruder. As you can see in the diagram, extruder feed gear, and filament feed guide is placed on a separate carriage system that contains the EXTRUDER.

With the filament, being fed via extruder feed gear and filament feed guide, towards a

filament tube.

Then once it passes through the filament feed tube, filament will then be directed to the cooling fins, heater block, then finally the nozzle.

By means of principle, both work the same as they feed the filament to the EXTRUDER.

The main difference is the placement of the feeding system which is composed of the extruder feed

gear and the filament feed guide, which will determine as well the presence of a filament feed tube.

We have discussed the EXTRUDER setup for DIRECT DRIVE and BOWDEN TYPE.

Now, we can list down some of the advantages and disadvantages of both setups. And later on, we can conclude which of the is better, technically on its application to FDM 3D Printing point of view.

DIRECT DRIVE EXTRUDER

ADVANTAGES

-Direct feeding of filament to EXTRUDER, making any type of filament compatible as well as feeding it easily through the EXTRUDER (Ranging from PLA, PETG, ABS, RUBBER, etc).

-Less part (Feed tube) which lessens the machine’Less part (Feed tube) which lessens the machine’s part maintenance to s part maintenance to be looked at.be looked at.

-Easy feeding of filaments to EXTRUDER. Absence of feed tube means ding of filaments to EXTRUDER.

-DIRECT DRIVE EXTRUDER’s feed and retraction can be calibrated easily.

DISADVANTAGES

-Weight of motor on the Carriage. Direct Drive’s setup requires the additional weight on the carriage.

-Heat Dissipation of motor to overall EXTRUDER setup. Motor’s heat will contribute to Carriage’s overall temperature.

BOWDEN TYPE EXTRUDER

ADVANTAGES

-Lighter Carriage on the EXTRUDER part results to less stress on the carriage’s motor.

-Less heat on the EXTRUDER part. Motor heat dissipated on other parts of the printer.

DISADVANTAGES

-Manufacturing or factory defects of filaments like bending, etc. will have a great effect on its flowthrough the filament feed tube.

-Flexible filaments tend not to flow smoothly through the feeding tube due to friction on the inside walls of the tube against the filament.

-Presence of feeding tube adds more to the calibration and maintenance of the machine.

-Overtime exposure of feeding tube to moisture, heat and others will affect its flexibility in due time, resulting to breakage of the tube.

Conclusion

So, Which one is best? Different answer for different people, it depends on your demands.

Both of the setups has its own advantages and disadvantages. Technically, Direct Drive Extruder is more advantageous than the Bowden Type Extruder. From having less part, thus, resulting in a simpler design.

“Good design is as little design as possible.” - Dieter Rams(IndustrialProductDesigner)

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.