Annealing in 3D printing makes PLA and PETG prints stronger. It heats the material to certain temperatures to change its structure. This helps prints resist heat better and become less brittle. Big companies often use annealing, but hobbyists may ignore it. Using this method, you can make parts handle more stress and heat. This makes them great for tough or long-term uses.

Key Takeaways

- Annealing makes PLA and PETG prints stronger and heatproof.

- Use full infill and clean prints first for better heating.

- Follow the right temperature and time: heat PLA to 60-70°C for 30-60 minutes, and PETG to 95-115°C for 45-90 minutes.

- Anneal parts needing strength or heat resistance; skip decorative ones to keep details.

- Watch the process carefully to avoid bending and get good results.

What Is Annealing in 3D Printing?

What Does Annealing Mean?

Annealing is a way to heat 3D prints to make them stronger. It heats the material to a certain temperature, then cools it slowly. This helps fix stress inside the print and makes the layers stick better. It also reduces problems like cracks or uneven cooling.

In 3D printing, annealing is used to:

- Make parts stronger for tough jobs.

- Help parts handle high heat without breaking.

- Stop warping and shrinking, so parts stay the right size.

|

Benefit |

What It Does |

|---|---|

|

Make Parts Stronger |

Fixes stress inside, making parts tougher for hard tasks. |

|

Handle High Heat |

Improves heat resistance, good for hot environments. |

|

Keep Shape Stable |

Stops warping and shrinking, keeping parts the right size. |

|

Boost Performance |

Great for strong, heat-resistant parts with carbon fiber. |

How Annealing Works: Heat and Molecules

Annealing works by heating the material until its molecules can move more freely. This happens at a special temperature called the glass transition temperature. The material doesn’t melt but becomes easier to adjust.

When annealing, the material’s structure relaxes and becomes more stable. Cooling it slowly helps reduce stress inside and makes it stronger. This process also fixes problems caused by fast cooling during printing. It creates better layer bonds and makes the print less likely to break.

Why Annealing Helps PLA and PETG

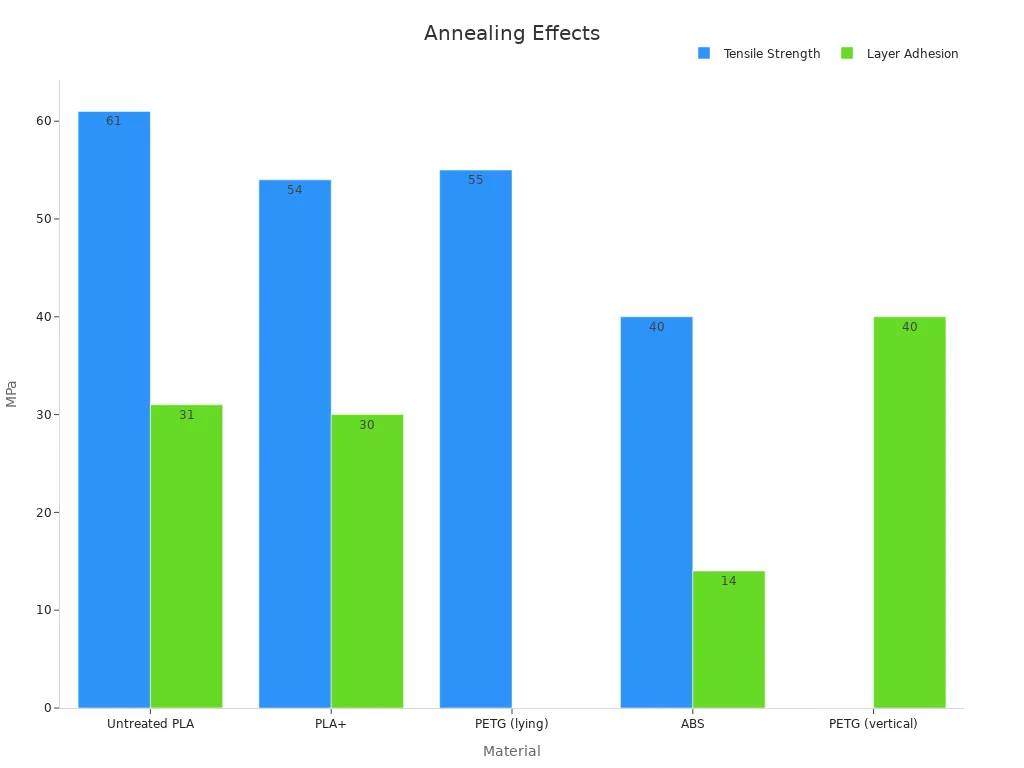

Annealing makes PLA and PETG prints much better. For PLA, it makes the material stronger and able to handle heat. Regular PLA has a strength of 61 MPa, but annealed PLA can be even stronger. PETG becomes tougher and keeps its shape better.

|

Material |

Strength (MPa) |

Layer Bond Strength (MPa) |

|---|---|---|

|

Regular PLA |

61 |

31 |

|

PETG (flat) |

55 |

N/A |

|

PETG (upright) |

N/A |

40 |

These changes make annealing great for parts that need to handle stress or heat. Whether you’re making test pieces or final products, annealing helps your prints last longer and work better.

How to Anneal PLA and PETG: Step-by-Step Guide

Getting Your Print Ready for Annealing

First, make sure your 3D print is ready. Use 100% infill for stronger parts during annealing. A line pattern works best to lower stress inside. Clean the print by removing brims, supports, or rough edges. This helps heat spread evenly and avoids weak spots.

Know your filament’s properties before starting. Find the glass transition temperature for PLA or PETG. PLA usually needs 60-70°C, while PETG needs higher, around 95-115°C. Think about how annealing will change strength and heat resistance. This helps you know how your print will perform after annealing.

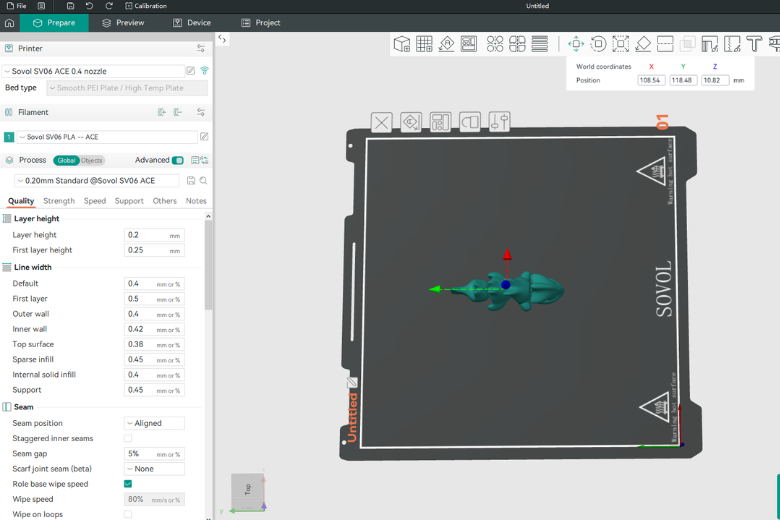

Annealing with an Electric Oven

An electric oven is a great tool for annealing. Preheat it to the right temperature—65-70°C for PLA or 95-115°C for PETG. Let the oven reach the set temperature before placing your print inside. Use a thermometer to check the temperature is correct.

Put the print on a flat, heat-safe tray. For PLA, anneal for 30 minutes per 1/4-inch thickness. PETG might need up to an hour. After annealing, turn off the oven and let it cool slowly. Don’t open the door during cooling. This prevents cracks or warping.

Other Methods: Heated Sand and Water Bath

No oven? Try heated sand or water baths instead. Heated sand supports the print well and stops bending. Put the print in a container of sand, preheat the oven to 95-115°C, and anneal for about an hour. This method heats and cools the print evenly.

Water baths are another option but may cause more warping. Submerge the print in hot water at the right temperature for a few minutes. Watch closely to avoid uneven heating. Sand annealing causes the least shrinkage, about 2.04%, while water baths may change the print more.

|

Method |

Deformation (%) |

Strength Increase |

Notes |

|---|---|---|---|

|

Sand Annealing |

Similar increase |

Least bending, best for keeping shape. |

|

|

Water Annealing |

N/A |

Similar increase |

May cause more warping. |

|

Glycerol Annealing |

N/A |

Small increase |

Does not stop bending or warping. |

Tip: Always wear gloves and safety glasses when working with hot materials. Keep the area ventilated and watch the process carefully for the best results.

Recommended Temperatures and Times for PLA and PETG

Getting the right heat and time is very important. PLA and PETG need specific settings to work best. Wrong settings can ruin or warp your print.

For PLA, heat it between 60°C and 70°C. This softens the material without melting it. Keep it in the oven for 30 to 60 minutes. Thicker prints might need more time, so check carefully. Always watch to make sure the heat stays steady.

PETG needs more heat, between 95°C and 115°C. It handles heat better and won’t bend as easily. Anneal it for 45 to 90 minutes, depending on how thick it is. Longer times help make it stronger and more stable.

Here’s a simple table for annealing:

|

Material |

Temperature Range (°C) |

Time (minutes) |

|---|---|---|

|

PLA |

60-70 |

30-60 |

|

PETG |

95-115 |

45-90 |

Tip: Use a separate oven thermometer to check the heat. Built-in ones can be wrong and cause uneven heating.

Annealing makes your 3D prints stronger and heat-resistant. Follow these tips to get better, longer-lasting prints.

How Different Filaments React to Annealing

PLA: Stronger and Handles Heat Better

Annealing makes PLA stronger and better at handling heat. Regular PLA softens at 60°C, but annealed PLA can take more heat. This is great for parts used in warm places.

But annealing PLA has some problems. It can shrink or warp if the heat changes too much. Use a steady heat source, like an electric oven, to avoid this. Make your prints a bit bigger before annealing to fix shrinkage issues.

PETG: Tough and Keeps Its Shape

PETG reacts differently than PLA when annealed. It’s already tough and flexible, but annealing makes it even better. It also keeps its shape well under heat or stress. This makes PETG perfect for strong parts used outside or under pressure.

PETG doesn’t shrink as much as PLA during annealing. But it needs higher heat, around 95°C to 115°C. Watch it closely to avoid overheating, which can ruin the print.

Special Filaments: Workday PLA and Pro PLA

Some filaments, like Workday PLA and Pro PLA, are made to be stronger. Annealing makes them even better for tough jobs.

Workday PLA has additives that make it less brittle. Pro PLA focuses on handling heat better. Both types shrink and warp less than regular PLA, so they’re easier to use.

|

Key Points |

Details |

|---|---|

|

Why Annealing Matters |

It helps filaments grow stronger and last longer. |

|

How It Works |

Annealing fixes the structure, making parts tougher. |

|

More filament ends mean better growth and strength. |

Annealing is very useful for improving 3D prints, especially with advanced filaments.

Tips to Reduce Warping and Shrinkage

Adjusting Print Size for Shrinkage

Annealing can make prints shrink or warp, especially PLA and PETG. To fix this, make your designs a bit bigger before printing. This helps the final size match what you want after annealing.

Different materials shrink differently. Semi-crystalline polymers like PEEK shrink more (1.5%) than amorphous ones (0.5%). Their densities also differ—semi-crystalline is 1.30 g/cm³, while amorphous is 1.26 g/cm³. This shows big volume changes.

Tip: Use design tools to scale models by 2-3% for PLA. This helps with expected shrinkage.

Watching the Annealing Process

Keep an eye on your print during annealing to avoid problems. Use a controlled heat source to keep the temperature steady. This is very important for PLA, which softens at lower heat.

Check the temperature with a separate thermometer. Built-in ones might not be accurate and can cause uneven heating. Don’t overheat, as it can ruin your print by melting or separating layers.

- Watch closely to stop overheating, which can melt prints.

- Use steady heat to avoid warping or bending.

Tip: Set a timer and check without opening the oven door. Sudden heat changes can crack or warp your print.

Picking the Right Parts for Annealing

Not all prints need annealing. Choose parts that need to be strong, heat-resistant, or stable in size. Functional items like gears or brackets are good choices.

Annealing makes parts stronger, reduces stress, and keeps their shape better. It also improves heat resistance, making parts last longer.

- Annealing makes parts tougher and reduces stress.

- It helps parts stay the right size and resist heat.

- Functional prints like gears or brackets benefit the most.

Tip: Don’t anneal decorative or detailed parts. Shrinkage can ruin fine designs. Focus on parts that need strength and durability.

Benefits and Limits of Annealing PLA and PETG

Better Strength and Heat Resistance

Annealing makes PLA and PETG stronger and better with heat. Heating changes the material’s molecules, making them more stable. This lowers stress inside and helps layers stick together. Studies show annealing improves strength by fixing weak spots. It also makes the material harder to bend and more durable.

PLA becomes much better at handling heat after annealing. Regular PLA softens at 60°C, but annealed PLA stays firm at higher temperatures. PETG, already tough, gets even stronger and resists impacts better. These changes make both materials great for parts that face heat or stress.

Problems: Warping, Shrinking, and Looks

Annealing can cause problems like warping and shrinking. PLA often shrinks unevenly as it cools, which can mess up its size. PETG shrinks less but can still bend if the heat isn’t steady. Studies show PLA shrinks less than ABS, but uneven shrinking is still an issue.

Annealing can also change how prints look. Parts might lose their smooth finish or become cloudy. This is fine for strong parts but bad for decorative ones. To avoid this, use steady heating and cooling methods.

Best Uses for Annealing

Annealing works best for parts that need strength or heat resistance. Gears, brackets, and cases are good examples. Research shows annealing nylon makes it stronger and more stable. But not all parts handle annealing well. PLA with fine details may shrink too much, and PETG with thin walls might bend under heat.

Choose parts that will face stress or high heat for annealing. Skip decorative or detailed prints, as they might lose their shape or look.

Annealing in 3D printing makes PLA and PETG prints stronger. It also helps them handle heat better and last longer. This process reduces brittleness, making parts tougher for daily use. Problems like warping or shrinking can happen, but you can avoid them. Prepare your prints well and watch the process closely to fix these issues. Trying annealing can help you make better 3D parts. It’s great for items that need to handle stress or high heat.

FAQ

How can you stop warping during annealing?

Use a steady heat source, like an electric oven. Place your print on a flat, even surface. Avoid quick temperature changes to keep it stable. Let the print cool slowly after heating to prevent warping. Sand annealing is also helpful for even heat and support.

Tip: Watch the process carefully to get the best results.

Can all PLA and PETG filaments be annealed?

Not every filament works well with annealing. Regular PLA and PETG are the easiest to anneal. Special filaments like Pro PLA or Workday PLA work even better. Always check the filament maker’s instructions before annealing.

How much does annealing shrink prints?

PLA shrinks about 2-3%, while PETG shrinks less, around 1-2%. The exact shrinkage depends on the filament and method used. Make your model slightly bigger before printing to adjust for this.

|

Polymer Type |

Shrinkage (%) |

Density (g/cm³) |

Volume Change (%) |

|---|---|---|---|

|

Amorphous Polymer |

0.5 |

1.26 |

N/A |

|

Semi-Crystalline PEEK |

1.5 |

1.30 |

>3 |

|

Material |

Shrinkage (%) |

|---|---|

|

PLA |

2-3% |

|

PETG |

1-2% |

Should decorative prints be annealed?

No, decorative prints don’t need annealing. The process can shrink or warp them, ruining small details. Annealing is better for strong, heat-resistant parts that need durability.

Can you anneal prints in a microwave?

Do not use a microwave for annealing. Microwaves heat unevenly and can ruin your print. Use safer methods like an electric oven, heated sand, or water baths instead.

Note: Be safe! Use the right tools and follow instructions when annealing.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.