Terephthalate glycol, commonly known as PETG, has emerged as a favorite material in the world of 3D printing. Its unique combination of strength, flexibility, and thermal resistance makes it an excellent choice for both beginners and professionals. PETG stands out due to its durability and ease of use, making it ideal for those new to 3D printing.

Why PETG is Beginner-Friendly:

- A 42% increase in tensile strength when comparing virgin PETG with recycled blends ensures your prints are strong and reliable.

- A 15% boost in elasticity allows for more flexible designs without compromising quality.

- The material can withstand temperatures up to 380 ºC, making it versatile for various applications.

These attributes not only enhance print quality but also simplify the learning curve for beginners. PETG is a material you can trust to deliver consistent results.

Key Takeaways

- PETG is tough and bendable, great for new 3D printers.

- Use a warm bed and right settings to stick prints better and stop bending.

- Keep PETG in sealed boxes to block water and get steady prints.

- Try different settings and fill designs to get better at 3D printing.

- PETG resists chemicals, so it works well outside and lasts long.

What is Terephthalate Glycol (PETG)?

Composition and properties of PETG

Terephthalate glycol, or PETG, is a glycol-modified version of polyethylene terephthalate (PET). This modification prevents crystallization, giving PETG its unique properties that make it ideal for 3D printing. PETG combines flexibility, toughness, and chemical resistance, making it a versatile material for various applications.

|

Property |

Details |

|---|---|

|

Chemical Composition |

PETG is a glycol-modified version of PET, preventing crystallization. |

|

Flexibility |

Retains flexibility, ideal for parts under physical stress. |

|

Toughness |

Impact-resistant, withstands drops and pressure without cracking. |

|

Temperature Resistance |

Glass transition temperature of 80°C, higher than PLA but lower than ABS. |

|

Chemical Resistance |

Highly resistant to chemicals and solvents, suitable for outdoor use. |

These properties ensure PETG delivers consistent performance, even under challenging conditions. Its ability to resist impact and maintain flexibility makes it a reliable choice for projects requiring durability and strength.

Why PETG is a popular filament for 3D printing

PETG has gained popularity in 3D printing due to its balance of strength, flexibility, and ease of use. Unlike some materials, PETG offers a beginner-friendly experience while maintaining professional-grade quality. Its ability to withstand physical stress and resist cracking ensures your prints remain durable over time.

- Statistical analysis shows PETG performs comparably to PLA and ABS in tensile stress tests.

- PETG's chemical resistance makes it suitable for outdoor and industrial applications.

- Its glass transition temperature of 80°C allows it to handle moderate heat exposure without deformation.

These factors make PETG a preferred choice for both hobbyists and professionals. Whether you're creating functional prototypes or decorative items, PETG provides the reliability you need.

How PETG compares to other 3D printing materials

When compared to other materials like PLA and ABS, PETG strikes a balance between ease of use and advanced performance. PLA is known for its simplicity and biodegradability, but it lacks the durability and temperature resistance of PETG. ABS, on the other hand, offers higher heat resistance but can be challenging to print due to warping and strong odors.

PETG stands out by offering:

- Greater flexibility than PLA, making it less prone to cracking.

- Easier printing than ABS, with minimal warping and no unpleasant fumes.

- Comparable tensile strength to both PLA and ABS, ensuring reliable performance.

This combination of properties makes PETG a versatile material for a wide range of 3D printing projects. Whether you're a beginner or an experienced user, PETG provides the perfect balance of quality and usability.

Why Use PETG for 3D Printing?

Advantages of PETG: Strength, flexibility, and durability

PETG offers a unique combination of strength, flexibility, and durability, making it a standout material for 3D printing. Its tensile strength of approximately 50 MPa surpasses that of ABS, ensuring your prints can handle significant stress without breaking. The material's flexibility allows it to absorb impacts effectively, reducing the risk of cracking under pressure. PETG also boasts an impact strength of 10-15 kJ/m², making it ideal for functional parts like phone cases and tool handles. These properties ensure your projects maintain their quality and reliability over time.

PETG's ease of use for beginners

PETG is one of the most beginner-friendly filaments available. It does not require a heated bed, making it accessible for entry-level 3D printers. The material offers excellent layer adhesion, resulting in smooth and consistent surfaces. Low shrinkage minimizes the risk of warping, even during longer printing sessions. These features simplify the learning process for new users, allowing you to focus on improving your skills rather than troubleshooting issues. PETG's forgiving nature ensures you can achieve high-quality results with minimal effort.

Applications of PETG in various 3D printing projects

The versatility of PETG makes it suitable for a wide range of applications. Its durability and chemical resistance make it perfect for outdoor and industrial use. You can create functional prototypes, decorative items, or even custom tools. PETG's ability to withstand physical stress and maintain its properties under challenging conditions ensures your projects remain reliable. Whether you're designing intricate models or practical components, PETG provides the flexibility and strength needed to bring your ideas to life.

How to Get Started with PETG 3D Printing

Choosing the right printer and PETG filament

Selecting the right printer and filament is crucial for achieving high-quality results with PETG. Start by ensuring your 3D printer supports PETG filament. Most FDM (Fused Deposition Modeling) printers are compatible, but you should verify that the printer can reach the required nozzle and bed temperatures. A printer with a heated bed and an all-metal hotend is ideal for handling PETG's thermal properties.

When choosing PETG filament, prioritize quality over cost. Look for filaments with consistent diameter tolerances (±0.02 mm) to avoid extrusion issues. Reputable brands often provide detailed specifications, including recommended printing temperatures and material properties. Opt for spools that are vacuum-sealed to prevent moisture absorption, as PETG is hygroscopic and can degrade in humid conditions.

Tip: Before purchasing, check online reviews and user feedback to ensure the filament performs well in terms of strength, flexibility, and adhesion.

Recommended printer settings for PETG

Proper printer settings play a significant role in achieving optimal results with PETG. Adjust your printer's parameters based on the filament manufacturer's recommendations and your specific project requirements. Below is a table summarizing the optimal settings for PETG:

|

Parameter |

Optimal Range |

|---|---|

|

Nozzle Temperature |

220°C - 250°C |

|

Bed Temperature |

70°C - 80°C |

|

Print Speed |

30 mm/s - 50 mm/s |

|

Retraction Distance |

4 mm - 6 mm |

|

Retraction Speed |

25 mm/s - 45 mm/s |

|

Cooling Fan Speed |

~30% |

These settings ensure proper extrusion, minimize stringing, and improve layer adhesion. Start with the lower end of the temperature range and gradually increase it if you notice under-extrusion. Keep the print speed moderate to maintain consistent quality, especially for intricate designs.

Note: PETG requires minimal cooling to prevent warping and maintain detail. Avoid setting the fan speed too high, as it can negatively impact adhesion between layers.

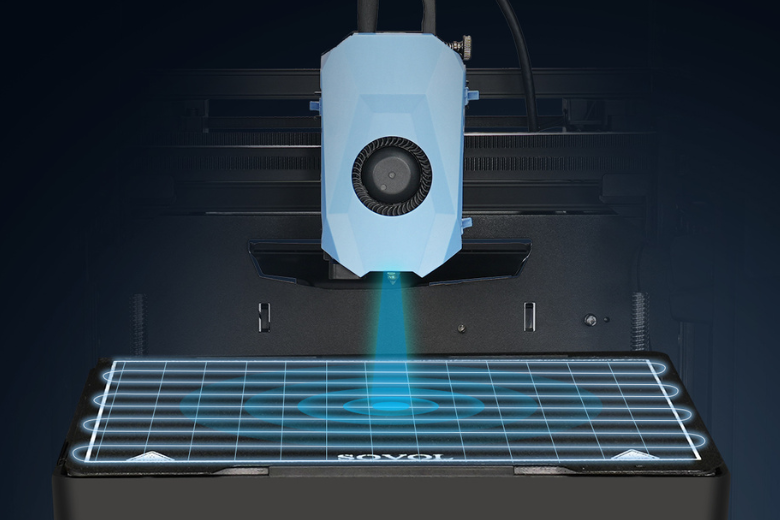

Preparing the print bed and handling PETG filament

Preparing the print bed is essential for successful PETG 3D printing. PETG adheres strongly to certain surfaces, which can make removal challenging. Use a heated bed set to 85°C and apply a release agent like glue stick or painter's tape to prevent excessive adhesion. Avoid smooth PEI sheets, as PETG can bond too tightly and damage the surface.

To ensure proper adhesion, clean the print bed thoroughly before each print. Remove dust, grease, or residue using isopropyl alcohol. For better results, consider using a textured or powder-coated sheet, which provides a balanced grip for PETG.

Handling PETG filament requires attention to its hygroscopic nature. Store the filament in an airtight container with desiccant packs to keep it dry. If the filament absorbs moisture, you may notice bubbling or inconsistent extrusion during printing. Dry the filament in a filament dryer or an oven at 60°C for 4-6 hours before use.

Pro Tip: Increase the number of perimeters for solid parts instead of relying on high infill percentages. This approach enhances strength and reduces material usage.

Common Challenges with PETG and How to Solve Them

Addressing stringing and oozing issues

Stringing and oozing are common challenges when working with PETG. These issues occur when excess filament leaks from the nozzle during non-printing movements, leaving thin strands on your model. To minimize stringing, adjust your printer's retraction settings. Start by setting the retraction distance between 4 mm and 6 mm and the retraction speed to 25-45 mm/s. These adjustments help pull the filament back into the nozzle, reducing leakage.

Travel speed also plays a crucial role. Set it to around 120 mm/s to limit the time the nozzle spends moving between print areas. Lowering the nozzle temperature by 5-10°C can further reduce stringing, as excessive heat makes PETG more prone to oozing. Additionally, ensure the filament is dry. Store it in a moisture-protected container or vacuum-sealed bag, and dry it at 60°C-65°C for 4-6 hours if needed.

Tip: Begin your print with the cooling fan off or at the lowest setting. Gradually increase it to 30-60% after the first few layers for better layer bonding and reduced stringing.

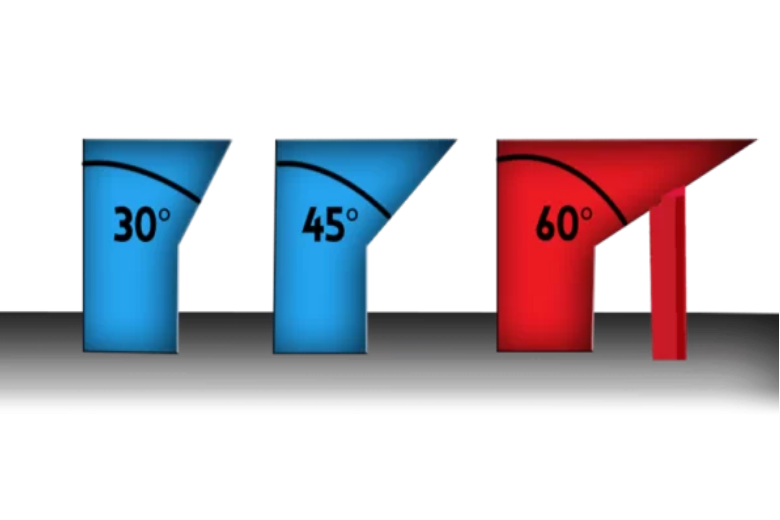

Preventing warping and improving bed adhesion

Warping occurs when the edges of your print lift off the bed, distorting the model. To prevent this, ensure proper bed adhesion. Set the bed temperature between 70°C and 90°C for optimal results. Applying a release agent like glue stick, blue painter's tape, or adhesive spray can enhance adhesion while making print removal easier.

Using brims or rafts is another effective strategy. These structures increase the contact area between the print and the bed, reducing the likelihood of warping. Cooling fan speed also impacts adhesion. Keep it between 0-30% to maintain consistent cooling without causing the edges to lift.

|

Solution Type |

Details |

|---|---|

|

Bed Temperature |

Set to 70°C-90°C for better adhesion. |

|

Adhesives |

Use glue stick, painter's tape, or adhesive spray. |

|

Brims and Rafts |

Add brims or rafts to increase bed contact area. |

Troubleshooting common PETG printing errors

When troubleshooting PETG printing errors, start by checking the extruder idler tension bolts. Loose bolts can cause inconsistent extrusion. Tighten them to ensure smooth filament flow. If stringing persists, lower the nozzle temperature slightly and verify your retraction settings in slicing software like PrusaControl.

Fan issues can also disrupt printing. Monitor the hotend fan's performance, especially if you notice overheating. Replace the fan if necessary to maintain stable temperatures. For persistent adhesion problems, clean the print bed with isopropyl alcohol to remove dust and grease. Applying a release agent can also help.

Pro Tip: Use slower speeds (20-30 mm/s) for the first few layers to enhance adhesion and prevent shifting during printing.

Tips for Success with PETG Filament

Proper storage and maintenance of PETG filament

PETG is a hygroscopic thermoplastic, meaning it absorbs moisture from the air. Improper storage can lead to bubbling, inconsistent extrusion, and reduced performance during printing. To maintain its excellent formability, store PETG filament in an airtight container with desiccant packs. Vacuum-sealed bags are another effective option for keeping the filament dry. If you suspect moisture absorption, dry the filament in a filament dryer or an oven at 60°C for 4-6 hours before use.

Regular maintenance of your filament ensures consistent results. Inspect the spool for dust or debris before loading it into your printer. Clean the nozzle periodically to prevent clogs caused by residual material. These simple steps will help you achieve reliable prints and extend the lifespan of your filament.

Tip: Label your filament spools with the purchase date to track their condition over time.

Optimizing print quality with temperature and speed adjustments

Achieving high-quality prints with PETG requires precise control of temperature and speed. Start by calibrating your printer using a temperature tower to identify the optimal nozzle temperature, typically between 230°C and 245°C. Adjust the bed temperature to 70°C-80°C for better adhesion. For speed, standard printers perform best at 40-60 mm/s, while specialized printers can handle speeds up to 350 mm/s.

Cooling plays a crucial role in preventing issues like oozing and warping. Use continuous cooling with fan speeds adjusted for different stages of the print. Begin with minimal cooling for the first few layers to enhance adhesion, then increase it to 30%-60% for improved detail and layer bonding.

- Temperature Range: 230°C-245°C for the nozzle, 70°C-80°C for the bed.

- Speed Recommendations: 40-60 mm/s for standard printers, up to 350 mm/s for advanced models.

- Cooling Requirements: Gradual fan speed adjustments for optimal results.

These adjustments will help you maximize PETG's potential and produce functional product design prototypes with precision.

Experimenting with PETG to enhance skills and results

Experimentation is key to mastering PETG and pushing the boundaries of your 3D printing projects. By testing different infill patterns, ratios, and settings, you can fine-tune your prints for specific applications. For example, a concentric infill pattern enhances vibration resistance, while higher infill ratios improve structural integrity. These adjustments are particularly useful for prototyping purposes or creating durable, functional parts.

|

Parameter |

|

|---|---|

|

Infill Ratio |

Increased natural frequency, storage modulus; decreased damping ratio |

|

Infill Pattern |

Concentric pattern exhibited the most desired vibration responses |

|

Experimental Findings |

Significant influence of parameters on dynamic mechanical behavior |

Experimenting with PETG not only improves your skills but also allows you to explore its versatility. Whether you're designing prototypes or functional components, these trials will help you unlock the full potential of this material.

Pro Tip: Keep a log of your experiments, noting the settings and outcomes. This practice will help you refine your techniques and achieve consistent results.

PETG offers numerous advantages that make it a standout material for 3D printing. Its strength, flexibility, and durability ensure reliable performance across various applications. Studies show that adding 10% weight of metal powder to PETG can enhance tensile strength by up to 48%, while maintaining excellent manufacturing quality. These benefits of PETG printing make it an ideal choice for both beginners and professionals.

You should consider experimenting with PETG to unlock its full potential. Its forgiving nature and versatility allow you to create everything from functional prototypes to intricate designs. By applying the tips shared in this guide, you can achieve consistent results and improve your 3D printing skills. PETG's balance of quality and ease of use makes it a material worth exploring.

FAQ

What makes PETG different from other filaments like PLA or ABS?

PETG, or polyethylene terephthalate glycol, offers a balance of strength, flexibility, and chemical resistance. Unlike PLA, it withstands higher temperatures and physical stress. Compared to ABS, it is easier to print and produces no unpleasant fumes. This makes it ideal for both beginners and professionals.

Can PETG be used for outdoor applications?

Yes, PETG is highly resistant to UV rays and moisture, making it suitable for outdoor use. Its durability and chemical resistance ensure that 3D printed PETG applications, such as garden tools or outdoor fixtures, maintain their integrity even in challenging environments.

How do I prevent PETG from sticking too strongly to the print bed?

Apply a release agent like glue stick or painter's tape to the print bed. This prevents excessive adhesion. Avoid smooth PEI sheets, as PETG can bond too tightly and damage the surface. A heated bed set to 85°C also helps with controlled adhesion.

Is PETG safe for food-related prints?

Food-safe PETG filaments exist, but you must verify the manufacturer's certification. Use a stainless steel nozzle to avoid contamination. Ensure the printed object is thoroughly cleaned before use. However, prolonged exposure to food or liquids may degrade the material over time.

How do I store PETG filament properly?

Store PETG in an airtight container with desiccant packs to prevent moisture absorption. PETG is hygroscopic, so exposure to humidity can cause bubbling and inconsistent extrusion. If the filament absorbs moisture, dry it in a filament dryer or oven at 60°C for 4-6 hours.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.