A blocked nozzle can bring your 3D printing projects to a halt. You can manage this issue effectively by identifying the root cause and taking prompt action. To ensure smooth operations, clean your 3D printer regularly and adopt proper maintenance practices. These steps will enhance print quality and reduce disruptions.

Key Takeaways

- Use good-quality filament to stop clogs. Bad materials may have dirt that blocks the nozzle.

- Clean your 3D printer nozzle often. Cleaning every two weeks keeps it working well and stops clogs.

- Keep filament in sealed containers to keep out moisture. Dry filament prints better and avoids clogs.

Common Causes of a Clogged Nozzle

Low-quality or contaminated filament

Using low-quality or contaminated filament often leads to nozzle blockages. Impurities in the filament can accumulate inside the nozzle, restricting the flow of material. Additionally, inconsistent filament diameter can cause uneven extrusion, increasing the risk of clogs. Always choose high-quality filament from reputable manufacturers to minimize these issues.

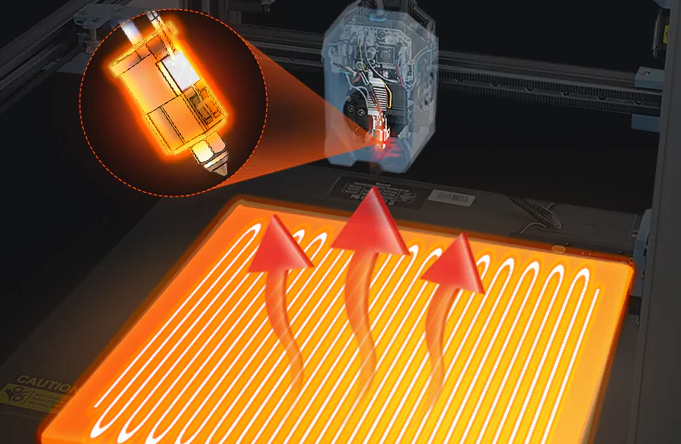

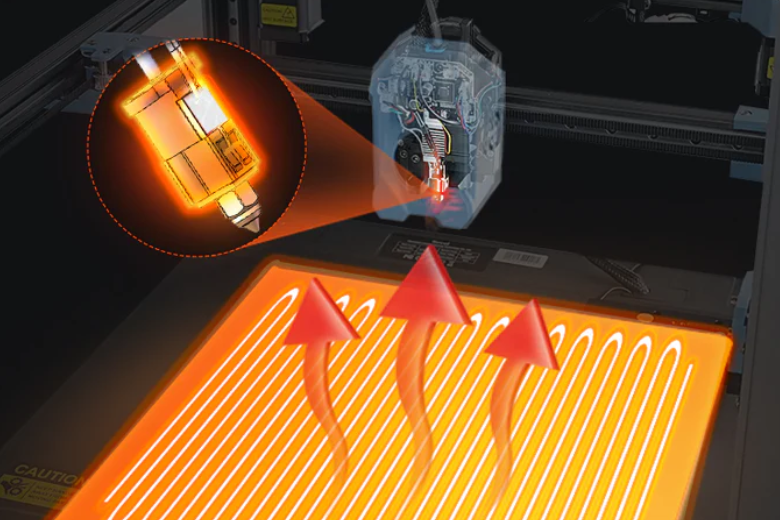

Incorrect 3D printing temperature settings

Temperature settings play a critical role in preventing nozzle clogs. High temperatures can cause stringing, where thin strands of filament connect different parts of the print. This can lead to inconsistent extrusion due to reduced material viscosity, ultimately affecting nozzle performance. Conversely, low temperatures may prevent the filament from melting properly, causing under-extrusion or complete blockages. Insufficient heat can also weaken interlayer adhesion, resulting in layer separation. Always refer to the filament manufacturer's recommended temperature range to avoid these problems.

Dust or debris inside the 3D printer nozzle

Dust and debris can easily enter the nozzle, especially if the filament is not stored properly. These contaminants can accumulate over time, leading to partial or complete clogs. To prevent this, store filament in sealed containers and regularly clean the nozzle to remove any buildup.

Filament degradation due to moisture absorption

Filament is highly susceptible to moisture absorption, which can degrade its quality and cause nozzle clogs. Moisture in the filament can create bubbles during extrusion, leading to inconsistent flow and potential blockages. The table below highlights the impact of moisture on filament performance:

|

Evidence Type |

Description |

|---|---|

|

Hygroscopic Nature |

Many plastics absorb moisture from the air, necessitating drying before use. |

|

Impact of Moisture |

Moisture can lead to defects such as bubbles or degradation in the filament. |

|

Nozzle Clogs |

Clogs can occur due to contaminants, carbonized material, or incomplete melting. |

To avoid these issues, store filament in a dry environment and use a filament dryer if necessary.

Improper retraction settings during printing

Incorrect retraction settings can also contribute to nozzle clogs. Retraction pulls the filament back into the nozzle to prevent stringing, but excessive retraction can cause molten filament to solidify inside the nozzle. This solidified material can block the nozzle and disrupt the printing process. Adjust retraction settings carefully to ensure smooth operation without causing clogs.

How to Unclog a 3D Printer Nozzle

Identifying a partial clog vs. a full clog

Before you begin unclogging, it’s essential to determine whether you’re dealing with a partial clog or a full clog. A partial clog occurs when the filament flow is restricted but not entirely blocked. You may notice inconsistent extrusion, under-extrusion, or thin, uneven layers in your prints. On the other hand, a full clog completely blocks the filament flow, causing the printer to stop extruding altogether. Identifying the type of clog helps you choose the most effective cleaning method for your 3d printer nozzle.

Using the cold pull technique for partial clogs

The cold pull method is an effective way to clear partial clogs. To perform this technique, heat the nozzle to the recommended temperature for the filament you’re using. Once the filament softens, lower the temperature slightly to allow it to solidify without becoming brittle. Then, manually pull the filament out of the nozzle. This process removes debris and contaminants stuck inside. Repeat the cold pull method a few times until the nozzle is clear. This technique works best for partial clogs and should be part of your regular nozzle cleaning routine to maintain optimal performance.

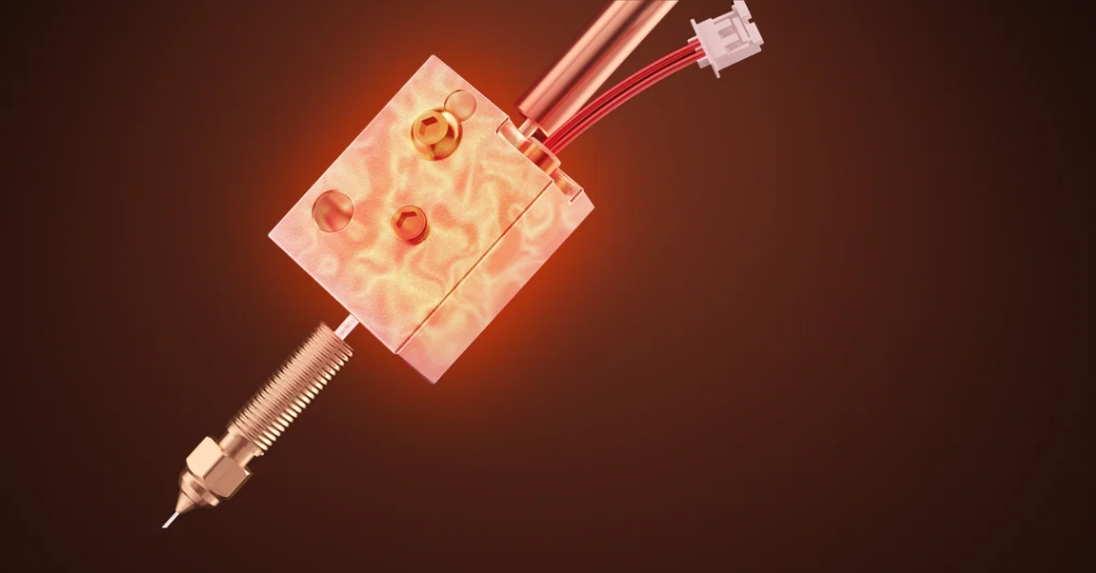

Cleaning the nozzle with a needle or wire

For stubborn clogs, using a fine needle or wire can be highly effective. Heat the nozzle to the appropriate temperature to soften any hardened filament. Then, carefully insert the needle or wire into the nozzle opening to dislodge debris. This cleaning method allows you to clear blockages and restore proper filament flow. Be cautious during this process to avoid damaging the nozzle. Regular use of this technique can prevent buildup and ensure smoother 3d printing operations.

Disassembling and soaking the nozzle in a solvent

If the clog persists, you may need to disassemble the nozzle for a more thorough nozzle cleaning. Remove the nozzle from the printer and soak it in a solvent, such as acetone, to dissolve any hardened filament. After soaking, use a soft brush or cloth to clean the nozzle thoroughly. Reassemble the nozzle once it’s completely dry. This method is particularly effective for full clogs caused by materials like ABS or PETG, which can leave residue inside the nozzle.

Using a specialized nozzle cleaning kit

Specialized nozzle cleaning kits are designed to simplify the unclogging process. These kits typically include fine needles, brushes, and cleaning rods tailored for 3d printer nozzle maintenance. Follow the instructions provided with the kit to remove blockages effectively. Using a cleaning kit not only resolves clogs but also helps you establish a consistent nozzle cleaning routine. This preventive approach minimizes the risk of future blockages and ensures better print quality.

Preventive Measures to Avoid Nozzle Blockages

Use high-quality filament for 3D printing

The quality of the filament you use directly impacts your 3D printing experience. Low-quality filament often contains impurities or inconsistent diameters, which can lead to filament buildup inside the nozzle. These imperfections restrict material flow and increase the likelihood of clogs. To prevent nozzle clogs, always choose filament from reputable manufacturers. High-quality filament ensures consistent extrusion and reduces the risk of buildup, resulting in smoother prints and fewer interruptions.

Store filament properly to prevent moisture absorption

Proper storage of filament is essential to maintain its quality and prevent moisture-related issues. Filament absorbs moisture from the air, which can lead to bubbles forming during extrusion. These bubbles disrupt the flow and cause filament buildup inside the nozzle. To avoid this, store filament in airtight containers with desiccants like silica gel. Plastic bags alone may not suffice, as they can allow humidity to seep in. Studies show that minimizing moisture content enhances the mechanical performance of 3D printed objects. By keeping your filament dry, you can prevent nozzle clogs and achieve better print quality.

Regularly clean the 3D printer nozzle and other components

Routine cleaning of your 3D printer nozzle and related parts is crucial for maintaining optimal performance. Over time, filament buildup and debris can accumulate, leading to clogs and inconsistent extrusion. A study on cleaning methods revealed that even simple techniques, such as soaking in warm soapy water, can remove up to 90% of contaminants. For more thorough maintenance, follow a cleaning schedule: inspect the nozzle daily, clean it bi-weekly, and perform a full hot-end disassembly quarterly. Regular cleaning not only prevents buildup but also extends the lifespan of your printer components.

|

Frequency |

Task |

|---|---|

|

Daily |

Inspect nozzle and print bed for debris |

|

Weekly |

Clean print bed and check belt tension |

|

Bi-weekly |

Thorough nozzle cleaning and lubrication |

|

Quarterly |

Disassemble and clean the hot end thoroughly |

Calibrate printer settings for optimal performance

Incorrect printer settings can lead to filament buildup and nozzle clogs. Calibration ensures that your printer operates within the ideal parameters for your chosen filament. Start by adjusting the temperature settings to match the filament manufacturer's recommendations. Incorrect retraction settings can also cause molten filament to solidify inside the nozzle, leading to clogs. Fine-tune these settings to minimize stringing without causing buildup. Regular calibration not only prevents nozzle issues but also improves the overall quality of your prints.

Minimize frequent filament changes without cleaning

Frequent filament changes can introduce contaminants or leave behind residue, increasing the risk of clogs. Each time you switch filament, remnants of the previous material may mix with the new one, causing filament buildup inside the nozzle. To avoid this, clean the nozzle thoroughly before loading a new filament. Using a cleaning filament during transitions can help remove leftover material and prevent buildup. By adopting this practice, you can reduce disruptions and maintain consistent print quality.

Troubleshooting Nozzle Issues by Filament Type

PLA-specific nozzle clogging issues and solutions

PLA is one of the most commonly used filaments in 3D printing, but it can cause nozzle blockages if not handled properly. You may encounter issues like filament sticking to the nozzle due to incorrect temperature settings or moisture absorption. To troubleshoot these problems:

- Check filament calibration by testing different profiles, such as Generic PLA or Bambu PLA.

- Dry the filament thoroughly, as even factory-sealed PLA can contain moisture.

- Clean the nozzle and other printer components, including lead screws and carbon rods, to remove debris.

- Adjust the print temperature within the recommended range (typically 190–220°C) to ensure smooth extrusion.

These steps will help you resolve PLA-specific clogs and improve print quality.

ABS-specific nozzle clogging issues and solutions

ABS filament is prone to clogging due to its higher extrusion temperature and tendency to leave residue inside the nozzle. You may notice filament sticking to the nozzle or inconsistent extrusion. To address these issues:

- Use a data-driven optimizer like ClogCalc, which has reduced clogging tendencies by 30%.

- Increase the addition of CaSi wire during extrusion, as higher amounts (0.17 kg/t) significantly decrease clogging events.

- Regularly clean the nozzle with acetone to dissolve hardened ABS residue.

These solutions enhance operational efficiency and reduce the frequency of ABS-related blockages.

PETG-specific nozzle clogging issues and solutions

PETG filament offers excellent durability but can cause filament sticking to the nozzle due to its sticky nature. To troubleshoot PETG clogs:

- Lower the print speed to reduce filament buildup inside the nozzle.

- Increase retraction settings slightly to prevent stringing.

- Clean the nozzle regularly to remove residue left by PETG’s adhesive properties.

These adjustments ensure smoother extrusion and minimize PETG-specific nozzle blockages.

Troubleshooting flexible filament blockages

Flexible filaments, such as TPU, often cause intermittent nozzle blockages due to their elasticity. You may experience filament sticking to the nozzle or binding issues. To resolve these problems:

- Bypass the side sensor and feed the filament directly to the toolhead to reduce friction.

- Adjust the position of the filament sensor and spool holders to alleviate binding.

- Replace the nozzle if wear is evident, although this may only provide temporary relief.

These troubleshooting steps improve the handling of flexible filaments and reduce disruptions during printing.

Specialty filament considerations for nozzle care

Specialty filaments like carbon fiber or wood-filled materials require extra care to prevent nozzle blockages. These filaments can leave abrasive residue inside the nozzle, causing filament sticking to the nozzle and reducing extrusion quality. To maintain nozzle performance:

- Use hardened steel or ruby-tipped nozzles designed for abrasive filaments.

- Clean the nozzle frequently with specialized cleaning kits to remove residue.

- Store specialty filaments in airtight containers to prevent moisture absorption.

By following these practices, you can extend the lifespan of your nozzle and achieve consistent results with specialty filaments.

Regular cleaning and proper filament handling are vital for maintaining your 3D printer's performance. Address nozzle blockages promptly to avoid disruptions and improve extrusion quality. Focus on first-layer adhesion and bed adhesion to ensure successful printing. Proactive care, such as cleaning the nozzle and calibrating settings, enhances adhesion and prevents extrusion issues.

FAQ

What are the signs of a nozzle blockage?

You may notice inconsistent extrusion, thin layers, or complete filament stoppage. These symptoms indicate a clog that requires immediate attention.

How often should you clean your 3D printer nozzle?

Clean the nozzle bi-weekly to prevent clogs. Regular maintenance ensures smooth filament flow and reduces the risk of nozzle blockage.

Can switching filaments cause clogs?

Yes, frequent filament changes without cleaning can leave residue inside the nozzle. Use cleaning filament during transitions to avoid buildup.

Zostaw komentarz

Wszystkie komentarze są moderowane przed opublikowaniem.

Ta strona jest chroniona przez hCaptcha i obowiązują na niej Polityka prywatności i Warunki korzystania z usługi serwisu hCaptcha.