A laser engraver is a machine that uses strong laser beams to carve or mark designs on different materials. This cool tool has changed industries by being accurate and flexible. It can make detailed designs on wood or add serial numbers to metal. Laser engraving is very important in today's technology.

Laser engraving has become more popular over time. For example:

-

The engraving services market grew from $254.02 million in 2023 to $273.47 million in 2024. It is expected to reach $432.32 million by 2030.

-

The global laser engraving machine market was worth $2,900.84 million in 2022. It is predicted to grow to $6,186.62 million by 2030, with a yearly growth rate of 9.93%.

Laser engravers are great for personal projects or business branding. They help you turn ideas into reality with amazing accuracy.

Key Takeaways

- Laser engravers use strong laser beams to make exact designs on different materials. They are important for personal and industrial projects.

- Picking the right laser engraver—diode, CO2, or fiber—depends on what you need. Think about the materials you’ll use and your budget.

- Taking care of your laser engraver is important. Clean the lens and check for good airflow to keep it working well and safe.

- Laser engraving can do many things. It’s used for custom gifts, home decorations, factory branding, and medical tools. It helps with creativity and saves time.

- Sovol laser engravers are great for beginners. They are easy to set up, have safety features, and work with popular design programs. They are perfect for new users.

How Laser Engraving Works

What is laser engraving?

Laser engraving uses a strong laser beam to make permanent marks. It works by heating the material's surface until it melts or vaporizes. This creates a clear and lasting design, like text or images. Unlike older methods, no tools touch the material, so it’s very precise and flexible.

This method is used in many industries, like cars, medicine, and fashion. It’s also great for art and hobbies. The laser beam can be as tiny as a few microns, making it perfect for detailed designs.

The science behind laser engraving technology

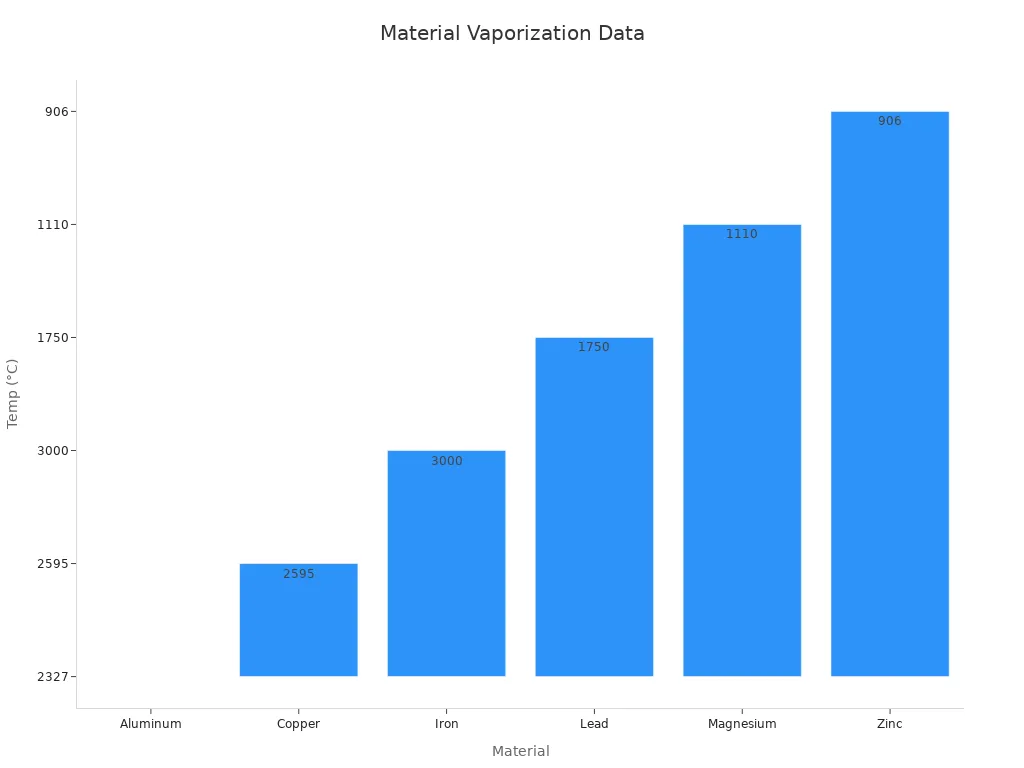

Laser engraving happens when light interacts with materials. A laser beam is a focused light stream that heats the material. The heat is so strong it turns the material into gas in milliseconds. For example, aluminum turns to gas at 2327°C, while zinc needs 906°C. Here’s a table of vaporization temperatures:

|

Material |

Vaporization Temperature |

|---|---|

|

Aluminum |

2327°C |

|

Copper |

2595°C |

|

Iron |

3000°C |

|

Lead |

1750°C |

|

Magnesium |

1110°C |

|

Zinc |

906°C |

When the laser hits the material, it creates small grooves. These grooves trap light, making the marks dark and easy to see. The depth of the engraving can go up to 0.5 mm, depending on the material and settings. This makes the marks last a long time.

Lasers also help study materials. For example, the Raman Effect shows how molecules react to lasers. This helps us understand how materials behave during engraving. Lasers can also cause chemical changes, allowing for precise adjustments to the material.

Key components of a laser engraver

A laser engraver has several important parts that work together. Knowing these parts helps you pick the right machine:

|

Component |

Description |

|---|---|

|

Laser Source |

Creates the laser beam. CO2 lasers are good for non-metals, while fiber lasers work best on metals. |

|

Optics System |

Uses mirrors and lenses to aim and focus the laser beam. |

|

Motion Control |

Moves the laser head along X and Y axes. Some machines can also engrave round objects. |

|

Turns your design into instructions for the machine, controlling speed and power. |

|

|

Exhaust or Fume Extraction System |

Clears away fumes and particles, keeping the workspace safe and clean. |

Each part is important for engraving. The optics system keeps the laser focused for detailed designs. The motion control system moves the laser smoothly. The software ensures your design is made exactly as planned.

Types of Laser Engravers

Laser engravers come in various types for different tasks. Knowing these types helps you pick the best one. The three main types are diode, CO2, and fiber laser engravers.

Diode laser engravers

Diode laser engravers are small and affordable machines. They use semiconductors to create a laser beam. These are great for beginners or hobbyists. You can engrave wood, leather, and some plastics with them. But they don’t work well on clear materials like glass.

Diode lasers are improving and becoming more powerful. They are now used for making custom gifts and small projects. If you want a low-cost option, a diode laser is a good choice.

CO2 laser engravers

CO2 laser engravers are strong and flexible tools. They use carbon dioxide gas to make the laser beam. These machines are perfect for engraving non-metal materials. Examples include wood, acrylic, leather, and glass. Their accuracy makes them popular in creative fields.

CO2 lasers are the top choice for engraving non-metals. They are great for detailed designs on home décor, signs, and fashion items. If you work with non-metals, a CO2 laser is a great option.

Fiber laser engravers

Fiber laser engravers are the most advanced type. They use optical fibers to strengthen the laser beam. These machines are best for engraving metals and some plastics. Industries like electronics and aerospace use them for their speed and durability.

|

Advantage |

Description |

|---|---|

|

Creates detailed and accurate engravings. |

|

|

Versatility |

Works on metals and some plastics, useful for many industries. |

|

Efficiency |

Fast operation increases productivity. |

|

Industry Applications |

Used in electronics, medical tools, jewelry, and more. |

Fiber lasers are becoming more popular in busy industries. They handle tough materials and detailed designs, making them ideal for professionals.

|

Laser Type |

Key Features and Growth Trends |

Market Insights |

|---|---|---|

|

Fiber lasers |

Over 10% yearly growth; known for precision and metal engraving |

Popular in high-demand industries |

|

CO₂ lasers |

Best for cutting and engraving non-metal materials |

Growing in creative and custom manufacturing |

|

Diode lasers |

Gaining power but limited with clear materials |

Expanding uses but facing some challenges |

Each laser engraver type has its own benefits. Your choice depends on your project and material needs.

Comparison of diode, CO2, and fiber laser engravers

Picking the right laser engraver depends on your tasks and budget. Each type—diode, CO2, and fiber—has its own strengths and weaknesses. Here's a simple comparison to guide you:

|

Laser Type |

Cutting Area Size |

Material Capability |

Cost Range |

Advantages |

Drawbacks |

|

|---|---|---|---|---|---|---|

|

Diode Laser |

6-15 |

Largest among the three |

Cannot cut or etch metal |

$200 - $3000 |

Portable, easily upgradeable, low cost |

Weak power, slow cutting, requires ventilation |

|

CO2 Laser |

30-130 |

Large, with pass-through |

Can cut thicker materials |

$2000 - $15000 |

Powerful, fast, enclosed with filtration |

Generates heat, large size, tube lifespan |

|

Fiber Optic Laser |

20-70 |

Small, less than 1 sq ft |

Can engrave metal |

$3000 - $20000 |

No cooling required, can engrave metal |

Small cutting area, no safety enclosure |

Diode lasers are great for beginners or hobbyists. They are cheap and easy to move. These lasers work well on wood, leather, and plastic. But they can’t cut or engrave metals. If you want a low-cost option for small projects, this is ideal.

CO2 lasers are stronger and more flexible. They can engrave wood, acrylic, and glass. Their bigger cutting area and faster speed make them good for businesses. However, they take up more space and need regular care because of heat.

Fiber lasers are best for professionals who work with metals. They are very precise and long-lasting. Industries like jewelry and aerospace rely on them. Although they cost more, their ability to engrave metals makes them worth it.

When thinking about costs, consider size, precision, and material use. Bigger engraving areas can double the price. Features like cooling systems can add 10-20% more. Knowing these details helps you pick a machine that fits your needs and budget.

Tip: Beginners should try a diode laser first. For advanced work, CO2 or fiber lasers are better choices.

Materials That Work with Laser Engraving

Laser engraving can be done on many materials. Each material offers unique ways to customize designs. Knowing how these materials behave helps you get the best results. Below are three common materials: wood and bamboo, metals, and plastics.

Wood and bamboo

Wood and bamboo are great for laser engraving. Their natural patterns make them perfect for detailed designs. You can use them for gifts, home decorations, or business signs. Softwoods like pine engrave faster, while hardwoods like oak give sharper details. Bamboo is eco-friendly and strong, making it ideal for cutting boards and coasters.

CO2 lasers work best for engraving wood and bamboo. They create clean designs without harming the material. But remember to have good ventilation. Engraving wood creates smoke and dust.

|

Best Laser Type |

Key Features |

|

|---|---|---|

|

Wood |

CO2 |

Easy to engrave, versatile |

|

Bamboo |

CO2 |

Strong, eco-friendly |

Metals (like stainless steel, aluminum, brass)

Metals need special lasers, like fiber or UV lasers, for precise engraving. These materials are used in industries for branding, serial numbers, and tools. Stainless steel and aluminum are strong and resist rust. Brass, with its gold color, is often used for decoration.

When engraving metals, adjust the laser settings carefully. Fiber lasers are great for detailed designs on metal. They are widely used in fields like jewelry, aerospace, and electronics.

|

Material Type |

Best Laser Type |

Key Features |

|---|---|---|

|

Stainless Steel |

Fiber, UV |

Strong, rust-resistant |

|

Aluminum |

Fiber, UV |

Light, easy to use |

|

Brass |

Fiber, UV |

Decorative, soft |

Plastics and acrylics

Plastics and acrylics are popular because they are cheap and flexible. They are used for signs, awards, and decorations. Acrylic gives a shiny finish that makes designs stand out. But not all plastics are safe for engraving. Check the material safety data sheet (MSDS) to avoid harmful fumes.

CO2 and fiber lasers can engrave plastics, depending on the type. For example, cast acrylic works well with CO2 lasers. Fiber lasers are better for some industrial plastics. Always follow safety rules to protect yourself and your workspace.

|

Aspect |

Details |

|---|---|

|

Safety Information |

|

|

Handling Practices |

Follow safety steps to avoid harmful fumes. |

|

Material Compatibility |

Use MSDS to check if the plastic is safe for engraving. |

Tip: Test a small part of the material first. This ensures it works well and gives the result you want.

Glass and ceramics

Glass and ceramics are great for laser engraving. They let you make detailed designs, perfect for gifts, awards, or decorations. Glass has a smooth surface that creates frosted engravings, which look amazing. Ceramics are strong and provide a lasting base for designs.

To engrave glass, use a CO2 laser. This laser makes clean marks without harming the glass. To avoid cracks or chips, place a damp paper towel or masking tape on the surface. This spreads the heat evenly. For ceramics, the laser removes the top glaze, showing the material underneath. This contrast makes the design stand out.

You can personalize glass items like mugs, wine glasses, or trophies. Ceramics work well for custom tiles, plates, or art pieces. Always ensure good ventilation because engraving these materials creates fine dust.

Tip: Test your design on a small spot first. This helps you check the settings and avoid mistakes.

Leather and textiles

Leather and textiles are flexible materials for laser engraving. Leather’s natural texture allows for classy, detailed designs. Textiles, like denim or felt, are great for creative patterns or logos. These materials are popular for fashion, accessories, and promotional items.

Use a CO2 laser for engraving leather. It makes neat marks without burning the surface. For textiles, adjust the laser settings to avoid cutting through the fabric. Always test a small area first to see how the material reacts.

Quality checks are important for leather and textiles. Manufacturers follow strict rules to ensure products last and look good. Here are some common checks:

|

Quality Check Type |

Purpose |

|---|---|

|

Visual Inspections |

Ensures engraving depth and design are consistent. |

|

Durability Testing |

Tests wear and tear to confirm long-lasting quality. |

|

Certification Standards |

Meets ISO and third-party standards for reliable products. |

Engraving leather is great for wallets, belts, or journals. Textiles, like canvas bags or t-shirts, can feature logos or custom designs. These make excellent gifts or promotional items.

Note: Always check the material’s safety data sheet (MSDS) to confirm it’s safe for engraving.

Step-by-Step Process of Laser Engraving

Preparing the design

The first step is to make your design. Use software like Adobe Illustrator, CorelDRAW, or free tools like Inkscape. These programs help you create files that fit your material size. Vector files are great for sharp and scalable designs. Raster files work better for detailed pictures.

Keep your design simple and clear. Avoid very complicated patterns that might not engrave well. Many software tools have helpful features like real-time previews and customization options. These tools improve accuracy and reduce mistakes. For example:

|

Feature |

Benefit |

Improvement Rate |

|---|---|---|

|

Customization Options |

Boosts user engagement |

Up to 30% |

|

Real-Time Previews |

Lowers return rates |

By up to 15% |

|

Mobile-Friendly Design |

Increases user retention |

By 25% |

Tip: Test your design on a small material piece first. This helps check alignment and accuracy.

Setting up the laser engraver

After your design is ready, set up the machine. Connect the laser engraver to your computer and load the design file into the software. Place the engraver on a steady surface with good airflow to clear fumes.

Next, adjust the laser focus. Set the right distance between the laser head and the material. Most machines have a focus tool or automatic focus to make this easier. Secure the material tightly on the engraving bed so it doesn’t move.

Then, configure the motion system. This system moves the laser head to follow your design. Check all connections and settings before starting.

Note: Always wear safety goggles to protect your eyes from the laser.

Choosing the right material and settings

Picking the right material and settings is key for good results. First, check if your material works with your laser type. For example, CO2 lasers are best for wood, acrylic, and leather. Fiber lasers are better for metals.

Test a small sample piece to find the best settings. Try different power, speed, and frequency levels to see what works. Start with low power and increase slowly to avoid damage. Keep the laser lens clean and the focus correct for even results.

Here are some tips for testing and adjusting settings:

- Test on a small sample before engraving the full piece.

- Write down each setting to track what works best.

- Keep the focus distance steady for consistent results.

- Follow the manufacturer’s guidelines and adjust as needed.

Tip: Testing saves time and helps you get the best engraving quality.

Engraving and finishing the product

Start engraving after setting up your design and machine. Run the laser engraver and watch it carefully. The laser beam will trace the design, making neat marks on the material. Some designs or materials may need extra passes for better depth. Test on scrap pieces first to avoid mistakes.

Check the product after engraving. Look for clear and sharp details. The design should match your original plan. If there are flaws, adjust the settings and try again. Advanced machines can spot errors during engraving to keep quality high.

Clean the engraved surface to finish the product. Use a soft cloth or brush to remove dust. For glass or metal, add coatings to protect the design. Coatings can stop scratches or damage from chemicals. This step keeps the product strong and looking good.

Quality checks are important for great results. Test the product for clarity, precision, and durability. Try scratch or chemical tests to see if the engraving lasts. These checks ensure your product looks nice and works well.

Tip: Clean the laser lens after each use. A clean lens helps the machine work better and last longer.

Applications of Laser Engraving

Hobbyist projects (e.g., personalized gifts, art, home decor)

Laser engraving is popular among hobbyists for creative projects. It lets you make custom gifts, detailed art, or unique home decorations. You can engrave materials like wood, glass, and leather to create special items. Examples include engraved cutting boards, photo frames, or plaques. These make great gifts or add a personal touch to your home.

People love personalized products more than ever. Websites like Etsy show the rising demand for engraved items. Artists use small laser machines to make custom jewelry or keychains. This trend is growing in places like North America, Europe, and Asia-Pacific, where crafting is popular. In the U.S., the craft supply market was worth $2 billion in 2021, showing how much people enjoy handmade goods.

|

Evidence Description |

Details |

|---|---|

|

Adoption Rates |

Portable laser engravers are widely used in North America, Europe, and Asia-Pacific. |

|

Craft Culture |

Platforms like Etsy support the strong craft culture in the U.S. |

|

Market Size |

Tip: Begin with small projects to learn how laser engraving works. This helps you understand the machine while making cool items.

Industrial uses (e.g., product branding, serial numbers, barcodes)

Industries use laser engraving for accurate and lasting marks. It’s great for adding serial numbers, barcodes, or logos to products. These marks help with branding, tracking, and meeting rules. For example, car and airplane companies use engraving to make tamper-proof marks on parts. These marks survive tough conditions like heat, scratches, and chemicals.

Laser engraving has many benefits for businesses. It makes products look better and improves brand visibility. The process is fast and reduces waste, saving money. It works on metals, plastics, and wood, with engraving depths between 0.002 and 0.005 inches. This ensures the marks stay clear and last a long time.

- Durability: Marks resist heat, scratches, and chemicals.

- Precision: Engraving improves product appearance.

- Efficiency: Less waste and lower handling costs.

- Traceability: Helps track parts during manufacturing.

Note: Laser engraving meets industry rules by creating clear and permanent marks.

Jewelry and fashion

Jewelry and fashion brands love laser engraving for detailed designs. You can personalize rings, bracelets, or pendants with names, dates, or patterns. This makes jewelry more meaningful and perfect for gifts. Fashion designers use engraving to add logos or designs to leather items like bags or belts.

Fiber lasers are best for engraving metals like gold, silver, and steel. They make detailed designs without harming the material. CO2 lasers work well for leather and fabrics, creating stylish accessories. Laser engraving is useful for both small artists and big fashion companies.

Tip: Try different materials and designs to make unique pieces that stand out.

Signage and advertising

Laser engraving helps make professional and attractive signs for businesses. It’s great for creating signs that grab attention and share messages clearly. From storefront signs to promotional displays, laser engraving ensures neat and long-lasting results.

A big benefit of laser engraving is its ability to work on many materials. You can engrave wood, acrylic, metal, or glass to make unique signs. For example, acrylic signs with engraved text or logos look modern and stylish, perfect for offices or stores. Wooden signs, however, give a cozy and rustic feel, great for cafes or small shops.

Laser engraving is very precise, allowing for detailed designs like logos, patterns, or fancy fonts. These details are hard to achieve with older methods. Engraved signs also last a long time and don’t fade, making them good for both indoor and outdoor use. This means your signs will stay useful for years.

For advertising, laser engraving can create items like plaques, awards, or branded products. These items help promote your brand and leave a strong impression on customers. Adding laser-engraved items to your marketing plan can make your brand stand out in a crowded market.

Tip: Pick materials that match your brand’s style. For example, metals show professionalism, while wood adds warmth and charm.

Medical and scientific tools

Laser engraving is very important in the medical and science fields. It’s used to mark tools and equipment with important details like serial numbers or barcodes. These marks help track items and meet safety rules.

Engraving is great for medical tools because the marks are permanent and clean. Unlike stickers or ink, engraved marks don’t wear off or collect germs. This makes them perfect for things like surgical tools and lab equipment. For instance, scalpels and test tubes can have unique marks to ensure proper use and tracking.

In science, laser engraving labels items like glassware, metal parts, or even delicate ceramics. This helps identify tools and samples, reducing mistakes during experiments. The precision of engraving allows for detailed labels, like measurement marks or chemical warnings, directly on the tools.

Another use is making custom tools and prototypes. Scientists and doctors often need special tools for their work. Laser engraving helps create these tools with exact details to meet their needs.

Note: Always check that engraved marks follow industry rules. This ensures tools are safe and work properly.

Key Factors to Consider When Buying a Laser Engraver

Power and performance

The power of a laser engraver is very important. It decides how well the machine can cut or engrave materials. Stronger lasers, like 100W ones, are great for metals. Weaker lasers, like 40W, work better on softer materials like wood or leather. For example, hobbyists often use 40W lasers for wood projects. Professionals prefer 100W lasers for engraving metals.

Performance also includes speed and accuracy. Fast machines save time but must stay precise for clean designs. Sovol laser engravers are a good mix of power and precision. They are great for beginners and give steady results on wood, acrylic, or leather.

Tip: Pick a laser with power that matches your material. Beginners can try mid-range machines like Sovol for easy use and flexibility.

Software compatibility

The software you use with your engraver is very important. It helps you create and adjust designs easily. Make sure the software works with your computer system. Many engravers support programs like LightBurn or LaserGRBL. These tools let you change settings and preview designs before engraving.

Choose software based on your skill level. Beginners should pick simple programs, while experts may want advanced options. Sovol engravers work with popular software, making them easy for both new and experienced users.

Note: Check if the software gets updates. Updates improve features and keep your engraver working well.

Safety features

Safety is very important when using a laser engraver. Look for machines with covers to block the laser beam. Air assist systems help reduce fumes, and emergency stop buttons let you quickly turn off the machine if needed. Always wear protective goggles to keep your eyes safe.

Sovol engravers have many safety features, like sturdy covers and simple controls. These make them a safe choice for beginners learning to engrave.

|

Description |

|

|---|---|

|

Safety Features |

Look for covers, air assist, stop buttons, and goggles to stay safe. |

|

Software Compatibility |

Make sure the software fits your skills and computer system. |

|

Accessories and Upgrades |

Check for extra tools and upgrades to improve your machine later. |

Tip: Always use your laser engraver in a space with good airflow. This helps reduce fumes and keeps the area safe.

Budget and intended use

When picking a laser engraver, think about your budget and purpose. Decide how you’ll use the machine. Are you making gifts for fun, or do you need it for work? Your goal will help you choose the right engraver.

For hobbyists, smaller and cheaper machines are a good option. These cost between $200 and $1,000. They work well on wood, leather, and acrylic. If you’re new to engraving, this is a great way to start without spending too much.

For businesses, stronger machines are better. They can handle metals and work faster. These professional machines cost from $2,000 to $20,000. While they are more expensive, they are precise and last longer.

Here are some tips to help you pick:

- Set a budget: Decide how much you can spend.

- Match to materials: Pick a machine that works with your materials.

- Plan ahead: If you want to grow, choose a machine with extra features.

Tip: Compare prices and features before buying. This helps you get the best deal.

Customer support and warranty

Good customer support and a strong warranty are very important. They help fix problems and keep your machine working well.

Choose brands with helpful customer service. Good companies give clear guides, troubleshooting help, and technical support. Some even have online groups where users share advice and tips.

A warranty protects your purchase. Most machines come with a one- to three-year warranty. This covers problems and lets you get repairs or replacements. Always check the warranty details to know what’s included.

Here’s what to look for:

- Warranty length: Longer warranties offer better protection.

- What’s covered: Make sure key parts like the laser are included.

- Support hours: Look for quick and available customer service.

Note: Sovol engravers are known for great support and warranties. They are a good choice for both beginners and experts.

Tips for Maintenance and Safety

Regular cleaning and inspection

Cleaning your laser engraver often helps it work better and last longer. Dust can block the laser lens, making it less accurate. After using the machine, wipe the lens gently with a soft cloth. Check for scratches or damage. Look at the moving parts every week to ensure they are clean and working well. Tighten any loose screws and add lubricant if needed.

Keeping your workspace tidy also prevents accidents. Arrange tools and materials neatly so you can move easily. Keep floors clean to avoid tripping. Use dust collection systems to capture particles while engraving. These systems help keep the air clean and reduce harmful dust.

|

Practice |

Details |

|---|---|

|

Keep tools organized and floors clean to avoid accidents. |

|

|

Dust Collection |

Use systems to trap dust and maintain clean air. |

Tip: Make a cleaning plan to keep your engraver in great shape.

Proper ventilation and workspace setup

Good airflow is important for safe engraving. Fumes from engraving can be harmful to breathe. Use ventilation systems to remove fumes right where they are made. Place your engraver near an open window or exhaust fan to improve air circulation.

Some engraving setups can be noisy. Mark loud areas clearly and wear ear protection if needed. A quiet, organized workspace helps you focus better on your projects.

|

Practice |

Details |

|---|---|

|

Local Ventilation |

Remove fumes at the source to keep the air safe. |

|

High Noise Areas |

Mark noisy spots and use ear protection when necessary. |

Note: Always check your workspace for safety risks before starting any project.

Using protective gear

Wearing safety gear protects you while using a laser engraver. Always wear goggles to shield your eyes from the laser. Gloves can protect your hands when handling sharp materials or cleaning the machine. If fumes are present, wear a mask to avoid breathing them in.

Make sure your safety gear fits well and meets safety rules. Replace damaged goggles or masks right away. Following these steps lowers risks and keeps you safe while engraving.

Tip: Use a safety gear checklist to stay prepared before starting your engraving work.

Updating software and firmware

Updating your laser engraver’s software and firmware keeps it working well. Updates fix problems, add features, and improve performance. Staying updated helps you get better results from your projects.

Check the manufacturer’s website or manual for update steps. Brands like Sovol often give easy guides or videos to help. Download the newest software version that works with your engraver. Before installing, save your current settings so you don’t lose them.

Firmware updates are just as important. Firmware controls how the machine moves and uses laser power. Updating it can make the engraver faster and more accurate. Use a USB cable or Wi-Fi to connect your engraver to your computer. Follow the steps to install the update. Don’t stop the process while it’s updating, as this might harm the machine.

Updates also help your engraver work better with design programs. For example, newer versions of LightBurn or LaserGRBL work best with updated machines. This ensures your designs look right and engravings stay consistent.

Tip: Check for updates every few months. This keeps your engraver running smoothly and avoids problems during engraving.

By keeping software and firmware updated, your engraver will work its best. This simple task saves time, improves quality, and helps your machine last longer.

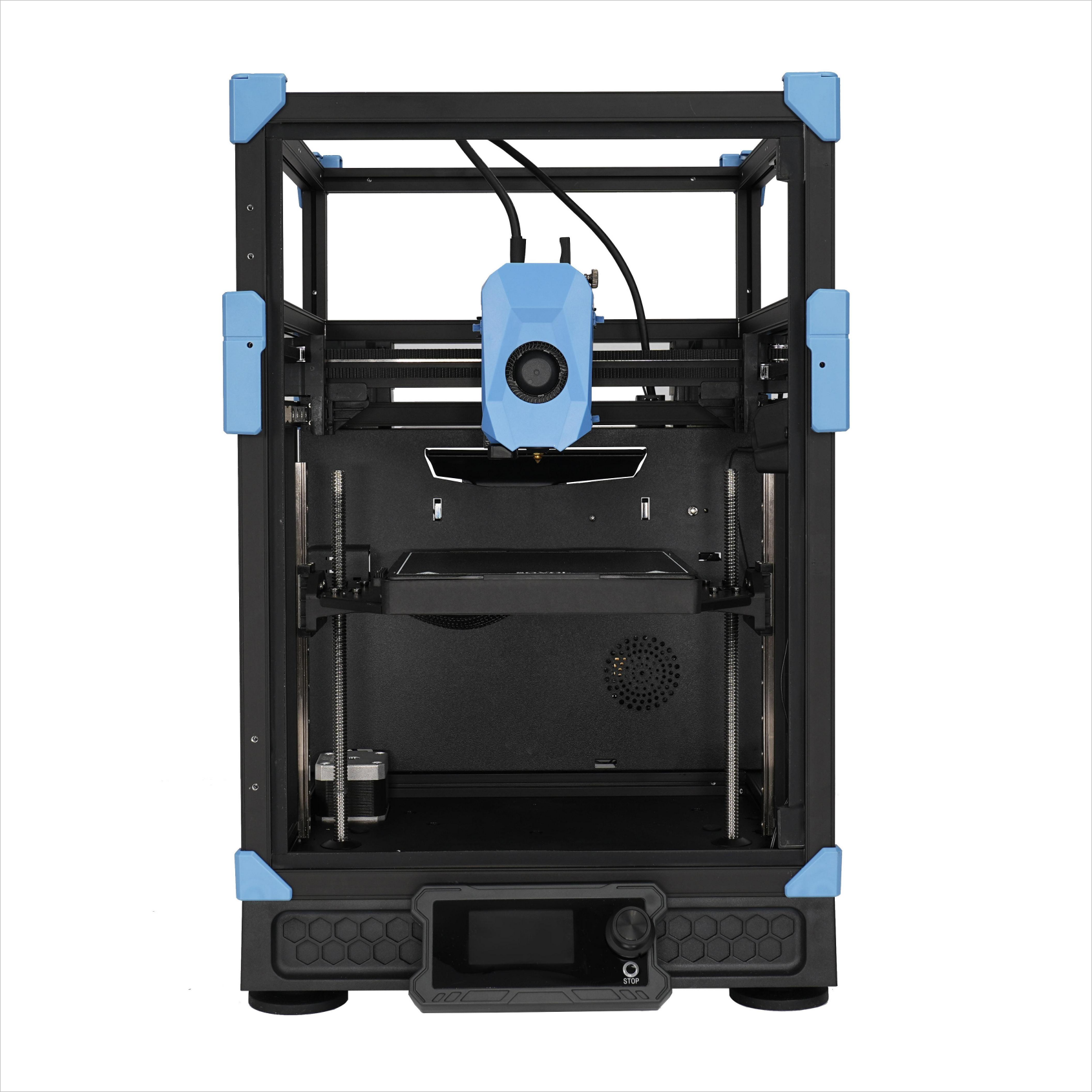

Why Sovol Laser Engravers Are a Great Pick for Beginners

What Makes Sovol Laser Engravers Special

Sovol laser engravers are made for both beginners and experts. These machines are easy to use and very steady. They can engrave many materials like wood, leather, and acrylic. If you want to make gifts or start a small business, Sovol can help. Their machines are small but strong, perfect for home or school use.

Beginner-Friendly Features of Sovol Machines

Sovol engravers have features that make them simple for new users. Setting up the machine is quick with clear instructions and easy software. Many models have automatic focus, so you don’t need to adjust it yourself. You can also change the power settings to work on different materials.

Safety is important too. Sovol machines have covers and stop buttons to keep you safe. They work with popular design programs, giving you lots of options for your projects. These features make Sovol a smart choice for beginners.

What Customers Say About Sovol

People love Sovol engravers for their great performance and lasting quality. Users say the machines make detailed and professional designs. Beginners like how easy they are to set up and use. Sovol is trusted by many because of its reliability and helpful support.

Whether you’re making crafts or running a small business, Sovol engravers give steady results. They are affordable, easy to use, and perfect for first-time users.

Laser engravers are super flexible tools. They can make detailed designs, customize gifts, or improve industrial tasks. These machines work on materials like wood, metal, and leather, making them useful for both fun and work projects.

Try it out! Whether you're crafting for fun or running a business, laser engraving lets you be creative and inventive.

Begin today and see how this tool can turn your ideas into real creations. Your imagination is the only limit!

FAQ

What materials can you engrave with a laser engraver?

Laser engravers can work on wood, metal, acrylic, leather, glass, and ceramics. Each material reacts differently to the laser beam. CO2 lasers are best for non-metals, while fiber lasers handle metals better. Always test a small piece first to get the best results.

How do you maintain a laser engraver?

Keep the lens and moving parts clean to ensure accuracy. Tighten any loose screws and add lubricant when needed. Make sure your workspace is free of dust and has good airflow. Follow the manufacturer’s care guide to keep the machine working well for a long time.

Is laser engraving safe to use at home?

Yes, laser engraving is safe if you take precautions. Wear safety goggles, use good ventilation, and place the machine on a steady surface. Many engravers, like Sovol models, have safety features like covers and stop buttons to keep you protected.

Can beginners use a laser engraver?

Yes! Many laser engravers, like Sovol ones, are made for beginners. They include simple instructions, beginner-friendly software, and safety features. Start with easy projects on soft materials like wood or leather to practice and improve your skills.

What software works with laser engravers?

Programs like LightBurn, LaserGRBL, and Inkscape are popular for creating designs. Check if your engraver works with these tools before choosing one. Sovol engravers support many of these programs, making them great for users of all levels.

Tip: Update your software often to enjoy better features and performance.

Zostaw komentarz

Wszystkie komentarze są moderowane przed opublikowaniem.

Ta strona jest chroniona przez hCaptcha i obowiązują na niej Polityka prywatności i Warunki korzystania z usługi serwisu hCaptcha.