Thermistors help make 3D printing accurate and consistent. These small sensors control temperature, keeping the printer working well. For example, they check the cartridge's heat during preheating. They send quick updates to advanced systems. This stops problems like warping or weak layer sticking. It also ensures the printer works reliably. Thermistors are important for 3D printing. They manage heat for materials like PLA or ABS. This allows smooth and good-quality prints.

Key Takeaways

- Thermistors help keep the right temperature in 3D printers. This ensures good-quality prints.

- Check your thermistor often to stop problems like overheating or wrong readings that can mess up prints.

- Use the right thermistor for your printer's software to avoid mistakes and keep it working well.

- Adjust your printer regularly so the thermistor matches the real temperature for the best print results.

- Knowing how thermistors work helps you fix and care for your 3D printer better.

What Is a Thermistor?

Definition and Functionality

A thermistor is a small electronic part that senses temperature changes. Its name comes from "thermal" and "resistor," showing its job: changing resistance when the temperature changes. Made from special materials, thermistors react quickly to even tiny temperature shifts. This makes them perfect for tasks needing exact temperature control.

Thermistors are used in many devices, such as:

- Checking temperature in tools like thermometers and air conditioners.

- Limiting electric current to stop power surges in circuits.

- Controlling heat in things like fridges and coffee machines.

In 3D printing, thermistors keep the hotend and heated bed at the right temperature. This helps materials work properly and creates high-quality prints.

Tip: Thermistors give real-time temperature updates, helping systems adjust heat accurately.

Types of Thermistors (NTC, PTC, 100K, etc.)

There are two main types of thermistors, based on how they react to heat:

-

NTC (Negative Temperature Coefficient):

These thermistors lose resistance as the temperature goes up. They are common in 3D printers because they are very sensitive and accurate. For instance, the 100K thermistor, a popular NTC type, is often used in printer hotends and heated beds. -

PTC (Positive Temperature Coefficient):

These thermistors gain resistance as the temperature rises. They are used to protect circuits from too much current.

|

Type |

Resistance Behavior |

Common Uses |

|---|---|---|

|

NTC |

Drops with higher temperature |

3D printers, thermometers |

|

PTC |

Rises with higher temperature |

Circuit safety, car systems |

The 100K thermistor, an NTC type, is widely used in 3D printing. It works well in a wide range of temperatures and gives steady readings.

How Thermistors Measure Temperature

Thermistors check temperature by noticing changes in their resistance. When the temperature shifts, their resistance changes too. The printer's system reads this change and shows the temperature.

For example, in a 3D printer, the thermistor in the hotend tracks the nozzle's heat. It sends data to the printer, which adjusts the heater to keep the right temperature. This ensures materials like PLA or ABS melt and flow smoothly, making neat and accurate prints.

Note: Thermistors can handle heat up to 200°C, making them great for high-temperature jobs like 3D printing.

The Role of Thermistors in 3D Printing

Monitoring Hot End Temperature

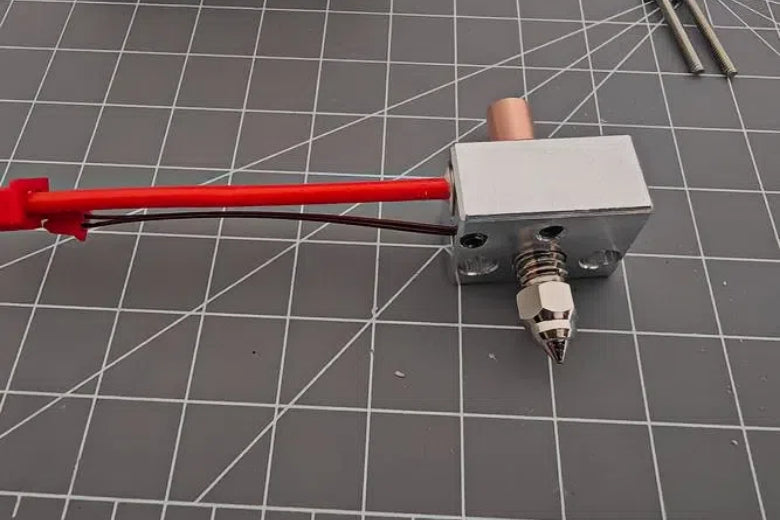

Thermistors are key to checking the hot end's heat. The hot end melts the filament before it is printed. Keeping the right temperature here is very important. It helps the filament flow smoothly and avoids clogs or uneven printing. A thermistor, like the 100K 3950 NTC thermistor, measures this heat nonstop. It sends the data to the printer's control board. The board then adjusts the heater to keep the needed temperature.

This careful monitoring also stops dangerous problems like thermal runaway. If the thermistor notices a sudden heat change, the printer can shut off the heater. This prevents overheating or damage. Broken thermistors or wrong readings can cause unsafe heat spikes. This shows why thermistors are so important for 3D printing.

Tip: Check your thermistor often to avoid print problems.

Regulating Heated Bed Temperature

The heated bed is another vital part of 3D printing. Thermistors make sure it stays at the right heat level. A steady bed temperature helps the first print layer stick well. This reduces problems like warping or detaching. Thermistors measure the bed's heat by sensing resistance changes. The printer uses this data to adjust the heater and keep the temperature steady.

For instance, a 100K thermistor might show these resistance values:

|

Temperature (°C) |

Resistance (kOhm) |

|---|---|

|

25 |

100 |

|

85 |

10 |

|

108.1 |

4.99 |

These numbers show how thermistors react to heat changes. They help keep the heated bed stable. But wrong firmware settings or bad calibration can cause errors. For example, one test showed a 17% difference in readings when using an Arduino. This proves the need for correct setup.

Note: Match your printer's firmware to the thermistor type to avoid errors.

Ambient Temperature Monitoring for Enclosed Printers

In enclosed printers, thermistors also check the air temperature inside. This is crucial for materials like ABS or nylon. These materials need steady heat to avoid warping or cracking. Thermistors measure the air heat and help keep it stable. This ensures good print quality.

For example, Sovol 3D printers like the SV06 ACE use thermistors to track chamber heat. The printer adjusts heaters or fans based on this data. Without this, changing air temperatures could ruin the print's strength.

Tip: If you use an enclosed printer, make sure the chamber's thermistor works well for the best results with heat-sensitive materials.

Why Accurate Temperature Control Matters

How It Affects Materials Like PLA, ABS, and PETG

Temperature control changes how materials like PLA, ABS, and PETG act. Each material needs a specific heat range to work well. For example, PLA melts at lower temperatures, around 190°C to 220°C. ABS needs more heat, about 230°C to 250°C. PETG falls in the middle, between 220°C and 250°C. Keeping these temperatures steady helps the material melt and flow properly. This makes prints strong and long-lasting.

Studies show higher nozzle heat improves material strength and flexibility. For instance, materials like PEEK become stronger with more heat. Keeping the air temperature steady also helps layers stick together better. Without good heat control, layers may not bond well. This can make parts weak or easy to break.

|

Material |

Nozzle Temp (°C) |

Bed Temp (°C) |

|---|---|---|

|

PLA |

190–220 |

50–60 |

|

ABS |

230–250 |

90–110 |

|

PETG |

220–250 |

70–90 |

How It Improves Print Quality

Good temperature control makes prints look and work better. When the nozzle and bed stay at the right heat, the filament flows evenly. This creates smooth layers and avoids problems like too much or too little filament. These issues can ruin how your print looks or works.

Experts say choosing the right filament and airflow is important. Too much heat can travel up the filament path, causing jams. This is called heat creep. A good thermistor helps you check and adjust heat in real time. This ensures each layer sticks well to the one below it.

Tip: Calibrate your printer often to match the thermistor's readings with the real temperature.

Stopping Problems Like Warping and Weak Layers

Bad temperature control can cause warping and poor layer bonding. Warping happens when the edges of a print lift off the bed. This is common with ABS, which shrinks as it cools. Using a heated bed at 90°C to 110°C can stop this problem.

Layer bonding also needs the right nozzle and bed heat. If layers don’t stick well, the print can fall apart or be weak. Cooling too fast can also cause defects. By setting the right heat for each material, you can avoid these problems and make better prints.

Note: Enclosures keep the air warm and steady. This reduces warping and helps layers stick for heat-sensitive materials.

Applications of Thermistors in 3D Printing

Hot End Temperature Regulation

Thermistors help control the hot end's heat in 3D printers. The hot end melts the filament before printing. Keeping the right heat ensures smooth filament flow. A thermistor checks the nozzle's heat and sends updates to the printer. This helps the printer adjust the heater and keep the temperature steady.

For example, when using PLA, the hot end should stay between 190°C and 220°C. If it gets too cold, the filament won’t melt and may clog. If it gets too hot, it can cause stringing or bad prints. Thermistors allow precise heat control, making prints consistent and high-quality.

Tip: Check your thermistor often to avoid problems from wrong heat readings.

Heated Bed Temperature Control

Thermistors also keep the heated bed at the right temperature. A steady bed heat helps the first layer stick well, stopping warping or peeling. Thermistors measure the bed's heat and send data to the printer. The printer adjusts the heater to keep the temperature stable.

|

Aspect |

Description |

|---|---|

|

Temperature Measurement |

Thermistors give accurate readings to maintain heated bed temperatures. |

|

Control Mechanism |

They work in a system that adjusts heat based on feedback. |

|

Impact on Print Quality |

Stable temperatures improve print quality and reduce errors. |

For instance, when printing with ABS, the bed should stay between 90°C and 110°C. Thermistors ensure this range is kept, stopping edges from lifting off the bed. This stability improves the print's overall quality.

Note: Use the right thermistor type for your printer's firmware to avoid errors.

Environmental Monitoring for Stability

In enclosed printers, thermistors check the air temperature inside. This is important for materials like ABS or nylon, which need steady heat to avoid warping or cracking. Thermistors measure the air heat and help the printer adjust heaters or fans to keep conditions stable.

- Thermistors are also used in other areas, like checking lake temperatures.

- Their sensitivity helps collect accurate data for better performance.

- Good measurements help meet rules and improve results.

In 3D printing, this sensitivity keeps the chamber at the right heat for tricky materials. For example, Sovol 3D printers use thermistors to stabilize the chamber's heat. This ensures good results, even with hard-to-print filaments.

Tip: Make sure your chamber's thermistor works well for the best results with heat-sensitive materials.

Common Thermistor Types and Their Uses

NTC Thermistors in 3D Printing

NTC thermistors are common in 3D printers. They are sensitive and reliable temperature sensors. Their resistance drops as the heat rises. This helps monitor heat accurately. They are found in the hotend and heated bed. These parts need steady heat for smooth printing and good adhesion.

100K Thermistors and Their Benefits

The 100K thermistor is a popular choice for 3D printers. It is an NTC type that gives accurate readings over a wide heat range. It is used in two main ways:

- Checking the hotend's heat to melt plastic smoothly.

- Watching the heated bed's heat to stop warping and help adhesion.

Comparing Thermistors to Other Sensors

Thermistors, PT100 sensors, and thermocouples all measure heat. But they differ in cost, accuracy, and range. Thermistors are best for 3D printing. They are quick, precise, and low-cost. PT100 sensors are more accurate but better for industrial jobs. Thermocouples handle extreme heat but miss small changes.

For 3D printers, thermistors are the best choice. They balance cost and performance well. They can handle up to 200°C, which works for most filaments like PLA and ABS.

Troubleshooting and Maintaining Thermistors

Finding Broken Thermistors (e.g., wrong readings, broken wires)

A broken thermistor can mess up your 3D printer. You might see wrong temperature numbers, heating problems, or error messages on the screen. These signs often mean the thermistor or its wires have issues.

To check for problems, look at the wires and plugs first. Broken wires or loose plugs can give wrong readings. Check them often to make sure they are okay. Another problem could be wrong firmware settings. The firmware must match the thermistor type to show correct temperatures. If the settings are wrong, the printer might not read the thermistor properly.

Tip: Use a multimeter to check the thermistor's resistance. If the number is off for the temperature, there’s an issue.

Fixing Heat Problems in Prints

Heat problems can ruin prints or make them fail. Warping, weak layers, or nozzle jams often happen because of bad temperature control. Start by checking the thermistor's readings. If the hotend or bed heat changes too much, the thermistor might be broken.

Make sure the firmware settings match the thermistor's specs. Wrong settings can make the printer too hot or too cold. Also, check where the thermistor is placed. If it’s in the wrong spot, it might not measure heat correctly, causing uneven heating.

Note: If you think the thermistor is broken, replace it quickly to avoid more problems.

Changing Thermistors: What to Check

When changing a thermistor, check a few things to make sure it works well. First, look at the temperature range. Most thermistors for 3D printers work between -50°C and 250°C. They are most accurate up to 150°C. For very high heat, glass-covered thermistors are better.

Check the resistance value and how it changes with heat. These details show how the thermistor reacts to temperature. Make sure the new thermistor matches your printer’s firmware to avoid mistakes. Also, think about the material covering the thermistor. Options like epoxy or glass give different levels of strength and protection.

Tip: Pick a thermistor with good noise resistance and quick cooling for better results.

Making Sure Your Thermistor Fits Your 3D Printer (e.g., Sovol-specific examples)

Picking the right thermistor helps your printer work well. Not all thermistors fit every printer, so check a few things first.

1. Match the Thermistor to Your Printer's Firmware

Your printer's firmware must support the thermistor you choose. Many printers, like Sovol models such as the SV06 ACE, use NTC thermistors like the 100K type. These are often pre-set in firmware, making setup simple. Before installing, check your firmware settings for the correct thermistor type. Sovol printers often use "Marlin" firmware, which includes common thermistor settings.

Tip: Look at your printer manual or firmware guide to find the right thermistor.

2. Check the Connector and Cable Length

Thermistors have different connectors and cable lengths. Make sure the connector fits your printer's control board. For example, Sovol thermistors usually have a 2-pin connector that works with most boards. Measure the distance from the thermistor to the control board. A short cable won’t reach, and a long one can make a mess.

3. Check the Temperature Range

Each thermistor works within certain heat limits. Most 3D printer thermistors handle up to 250°C, good for materials like PLA and ABS. If you use high-heat filaments like nylon, make sure the thermistor can handle it. Sovol thermistors are built for these ranges, ensuring they work well.

|

Feature |

Sovol Thermistor Example |

Why It Matters |

|---|---|---|

|

Type |

100K NTC |

Accurate heat readings |

|

Connector Type |

2-pin |

Easy to install |

|

Temperature Range |

-50°C to 250°C |

Works with most materials |

4. Test After Installing

After installing, test the thermistor by heating the hotend or bed. Watch the temperature on the printer’s screen. If it seems wrong, check the firmware and wiring. Sovol printers, like the SV08, have easy-to-use screens to help fix problems.

Note: Turn off your printer before testing or replacing a thermistor to stay safe.

By following these steps, you can make sure your thermistor works perfectly with your printer. Sovol thermistors are simple to install and reliable, helping you get great prints every time.

Thermistors are important for keeping the right temperature in 3D printers. They help make prints accurate and reliable by managing heat well. Knowing how thermistors work and where they are used improves printing. Checking and replacing broken thermistors keeps your printer working properly. Taking care of this small part stops problems and helps you make great prints every time.

FAQ

1. What happens if a thermistor stops working during printing?

A broken thermistor can give wrong temperature readings. This might cause the printer to overheat, underheat, or fail to print. Stop the printer right away and check the thermistor for damage or loose wires. Replace it if needed to fix the temperature control.

2. How do you pick the right thermistor for your printer?

Make sure the thermistor works with your printer’s firmware. Check its temperature range and that the connector fits your printer’s board. For Sovol printers, the 100K NTC thermistor is a good option for materials like PLA and ABS.

3. Can thermistors handle high-heat filaments like nylon?

Yes, but the thermistor must work above 250°C. Glass-covered thermistors are better for high-temperature printing. Always check the thermistor’s details before using it with heat-sensitive materials.

4. How often should you check your thermistor?

Check your thermistor often, especially before long prints. Look for worn parts, loose wires, or wrong temperature readings. Regular checks help avoid print problems and keep your printer working well.

5. What tools can you use to test a thermistor?

A multimeter is great for testing thermistors. Use it to measure resistance at room temperature and compare it to the correct value. If the number is far off, the thermistor might need to be replaced.

Yorum yazın

Tüm yorumlar yayınlanmadan önce incelenir.

Bu site hCaptcha ile korunuyor. Ayrıca bu site için hCaptcha Gizlilik Politikası ve Hizmet Şartları geçerlidir.