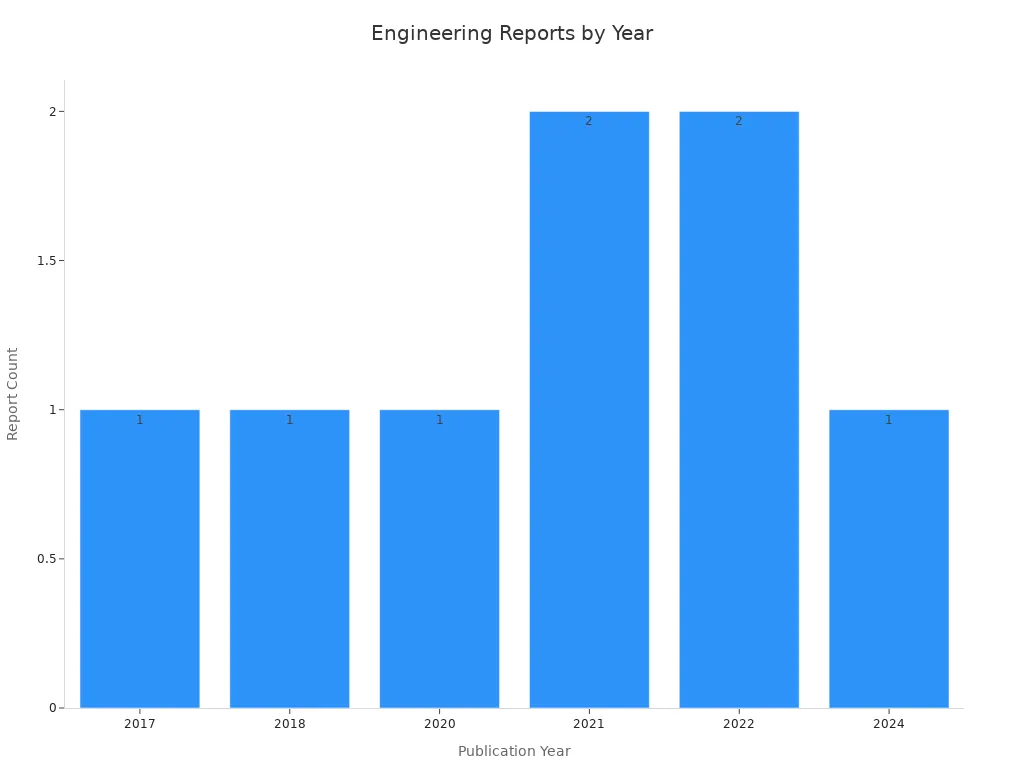

When thinking about 3D printing, 3D printing resolution is very important. It determines the smallest details your printer can create. The resolution affects the overall appearance of the print, including smooth surfaces and intricate features. High 3D printing resolution is crucial for applications like medical models, where precision is essential. Research indicates that stepper motors, which control the movement of the print head, significantly impact 3D printing resolution. Smaller motor steps lead to better movements, enhancing print quality. Understanding 3D printing resolution helps you maximize the performance of your 3D printer.

Key Takeaways

- 3D printing resolution shows how small details your printer can make. Higher resolution gives smoother surfaces and better details, great for things like medical models.

- Changing layer height and nozzle size helps improve print quality. Smaller layers, like 0.1mm, add more detail. Nozzle size changes how sharp edges look.

- Taking care of your printer keeps it working well. Clean the nozzle and print bed often. Check for parts that might be out of place to keep prints looking good.

- Picking the right material affects how good prints look. Materials like PLA are easy to use and make smooth prints. Resin is best for tiny, detailed designs.

- Trying advanced slicer settings can make prints much better. Test different layer heights and speeds to find what works best for your projects.

What is 3D Printing Resolution?

What 3D printing resolution means and why it matters

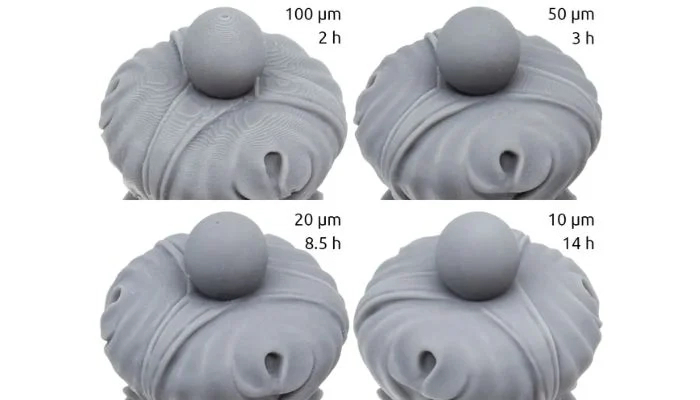

3D printing resolution shows the smallest detail your printer can make. It is key to how good and accurate your prints look. Resolution is measured in microns (µm). Smaller numbers mean better precision. For example, home SLA printers can print at 50µm, but industrial ones can go down to 30µm. This shows how technology has made printers more precise over time.

Resolution is important for more than just looks. It affects accuracy, precision, and repeatability. Accuracy makes sure printed parts match the design, which is vital for things like medical tools. Precision ensures prints are consistent every time. Repeatability lets you make identical parts with little difference. These features make resolution essential for high-quality printing.

|

Feature |

Importance |

|---|---|

|

Accuracy |

Makes sure parts match the design, needed for medical tools. |

|

Precision |

Ensures prints are consistent, important for uniform results. |

|

Repeatability |

Helps printers make identical parts with little variation. |

|

Resolution |

Shows the smallest detail a printer can make, based on its hardware. |

How resolution changes print quality and details

Your printer's resolution affects how smooth and detailed your prints are. Higher resolution gives smoother surfaces and finer details, great for complex designs. For example, a high-resolution printer can show tiny textures and sharp edges on small models that low-resolution printers miss.

But high resolution has downsides. Printing at finer resolution takes longer because the printer uses thinner layers. Even though it takes more time, the better quality is worth it for detailed projects.

|

Feature |

Improvement |

|---|---|

|

Thinner layers make smoother surfaces by reducing visible steps. |

|

|

Beam Diameter |

Smaller beam sizes allow for finer details and higher resolution. |

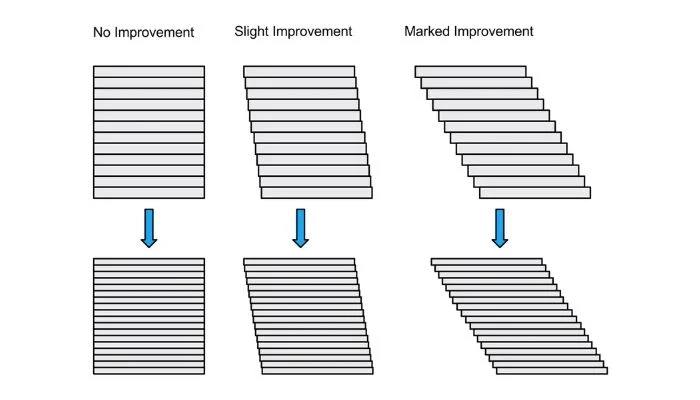

How layer height helps achieve better resolution

Layer height is very important for 3D printing resolution. It means how thick each layer is during printing. Smaller layer heights make smoother surfaces and better details by reducing visible steps between layers. Tests show that a 0.15mm layer height gives the best strength and stickiness, better than thicker layers like 0.3mm or 0.4mm.

Smaller layer heights also improve accuracy. Studies show that 0.1mm layer height reduces errors, making printed parts closer to the design. But smaller layers take longer to print because more layers are needed to finish the model.

- Tests show 0.15mm layer height gives the best strength and stickiness.

- Thicker layers, like 0.3mm, are weaker, showing layer height matters for resolution.

- Data shows 0.1mm layer height improves accuracy, reducing errors from material flow.

Choosing the right layer height balances print quality, detail, and time. This is especially useful for projects needing fine details and high accuracy.

Factors Influencing 3D Printing Resolution

How layer height changes resolution

Layer height means how thick each printed layer is. Smaller layers make smoother prints and show tiny details. Bigger layers print faster but look rougher. For example, 0.1mm layers look polished, while 0.3mm layers may show ridges.

Layer height also affects strength. Research shows thicker ABS layers, like 0.28mm, are weaker than thinner ones, like 0.16mm. PLA layers lose even more strength when thicker. Picking the right layer height balances smoothness, detail, and durability.

How nozzle size affects print details

Nozzle size controls how much material comes out. Small nozzles make sharp edges and detailed designs. Big nozzles print faster but lose detail and smoothness.

Studies say small nozzles push material faster, making finer prints. Big nozzles work better for quick, simple projects.

Choose nozzle size based on your design. Use small nozzles for detailed models. Use big nozzles for larger, less detailed prints.

Printer type and technology (e.g., FDM, SLA, DLP)

Different printers use different methods to print. Each type has its own strengths.

- FDM printers are cheap but struggle with tiny details.

- SLA printers use lasers and resin for high detail.

- DLP printers use light to cure resin, making smooth prints.

Tests show SLA and DLP printers are better for detailed work, like dental models. Knowing your printer's abilities helps you pick the best one for your needs.

Material choice and its role in achieving high resolution

The material you pick affects how good your prints look. Different materials have special traits that change the details and quality. Knowing how materials affect resolution helps you choose better for your projects.

Some materials, like PLA, are simple to use and make smooth prints. PLA is perfect for beginners or when you want easy, detailed results. ABS is stronger but might shrink, making prints less precise. For flexible prints, TPU works well but needs careful settings to keep details.

Resin materials, used in SLA and DLP printers, give the best details. These materials harden with light, creating very fine designs. But they cost more and need extra steps, like cleaning and curing, for top results.

Think about your printer and project needs when picking a material. For strong parts, durability may matter more than details. For artistic models, choose a material that shows tiny features well.

Try different materials to find what works best for you. Always follow the maker’s tips for the right settings, as these differ by material. Picking the right material can greatly improve your print’s details and quality.

How to Improve 3D Printing Resolution

Adjusting layer height and nozzle size for better prints

To get better 3D printing resolution, adjust layer height and nozzle size. Layer height is how thick each printed layer is. Nozzle size controls how much material comes out. Both affect the details and quality of your prints.

Smaller layer heights, like 0.1mm, make smoother surfaces and finer details. But if the layer height is too small, it can cause pressure problems and surface flaws. Larger layer heights, like 0.3mm, print faster but lose detail and accuracy. Finding the right balance is key.

Nozzle size is also important. Small nozzles, like 0.2mm, create sharp edges and detailed designs. Bigger nozzles, like 0.6mm, print faster but lose detail. Keep layer heights between 25% and 80% of the nozzle size for the best results.

|

Aspect |

Detail |

|---|---|

|

Nozzle Size Impact |

Nozzle size affects the layer heights you can use. |

|

Layer Height Recommendations |

Layer heights should be at least 25% of nozzle size. |

|

Minimum Layer Height Issues |

Very small layer heights can cause pressure and flaws. |

|

Maximum Layer Height Limit |

Heights over 80% of nozzle size weaken layer bonding. |

|

Optimal Width-to-Height Ratio |

A 3:2 width-to-height ratio works well for quality. |

By adjusting these settings, you can improve print details and quality. Sovol 3D printers are great for controlling layer height and nozzle size, making them a good choice for high-resolution projects.

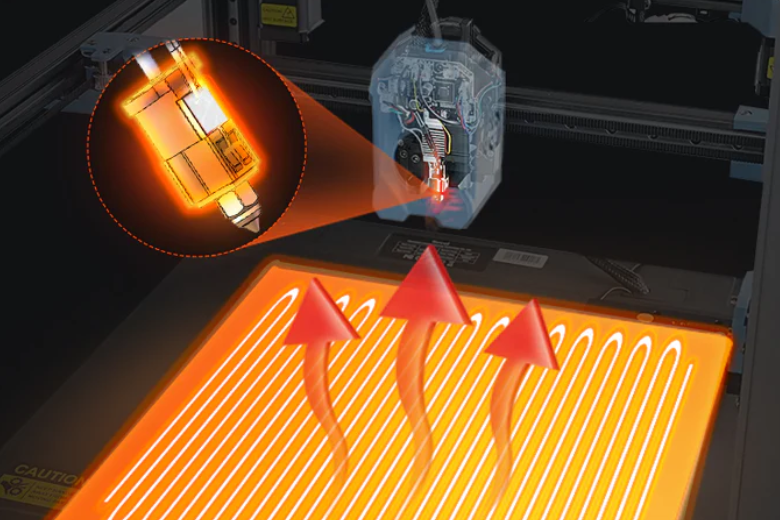

Changing print speed and temperature for better quality

Print speed and temperature affect how good your prints look. Faster speeds save time but can cause problems like rough surfaces or weak layers. Slower speeds take longer but give better details and accuracy.

Higher temperatures help with faster speeds by keeping material flowing. But too much heat can cause extra material to stick out, ruining the surface. Lower temperatures work better with slower speeds, reducing mistakes and improving quality.

Things to watch when changing speed and temperature:

- Ringing or ghosting: Fast speeds can cause vibrations, making surfaces uneven.

- Poor layer adhesion: Fast printing can weaken the bond between layers.

- Under-extrusion: Happens when material flow can't keep up with speed, causing gaps.

- Lower dimensional accuracy: Fast speeds can make the final size less accurate.

- Part strength reduction: High speeds may make the object weaker.

Different materials need different settings. For example, PLA works best with slow speeds and low temperatures for small prints. PETG needs higher settings for bigger models. Testing these settings helps you find the best balance for high resolution.

Picking good materials for better prints

The material you use affects how detailed and smooth your prints are. High-quality materials give better results with fewer problems. PLA is easy to use and makes smooth, detailed prints. ABS is stronger but might shrink, which can affect accuracy. TPU is flexible but needs careful settings to keep details.

Resin materials, used in SLA and DLP printers, give the best details. They harden with light, making very fine designs. But resin costs more and needs extra steps, like cleaning and curing, for the best results.

When choosing materials:

-

Use PLA for smooth and easy prints.

-

Pick ABS for strong parts but plan for shrinkage.

-

Choose TPU for flexible designs but adjust settings carefully.

-

Go with resin for projects needing very fine details.

Sovol 3D printers work with many materials, making them a good choice for high-resolution printing. Always follow the material maker's instructions for the best results.

Regular maintenance and calibration of the printer

Taking care of your printer is key to better 3D printing resolution. A clean and calibrated printer works more accurately and consistently. Skipping maintenance can cause problems like misalignment and bad print quality.

Start by cleaning your printer often. Dust and dirt can build up on the nozzle, print bed, and other parts. This can hurt how well layers stick together and lower resolution. Use a soft brush or compressed air to clean hard-to-reach spots. For the nozzle, heat it up and use a cleaning filament or needle to clear clogs.

Calibration is just as important. First, check the print bed. If it’s uneven, layers can shift and ruin details. Use the leveling tool on your printer or adjust the screws to make the bed flat. Then, calibrate the extruder. Wrong extrusion rates can cause too much or too little material, affecting print quality. Measure the filament flow and adjust slicer settings to fix this.

Look at the belts and pulleys. Loose belts can cause shaking, making prints less precise. Tighten them if needed, but don’t overtighten to avoid motor strain. Lubricate moving parts like rods and bearings to keep them running smoothly.

After calibrating, do a test print. This helps you check if the adjustments worked and spot any other issues. Sovol 3D printers are easy to calibrate and help you get high-resolution prints.

Tip: Make a schedule for regular maintenance. Checking and fixing your printer often saves time and improves print quality.

Upgrading to a high-resolution printer for advanced precision

If you need very detailed prints, think about getting a high-resolution printer. While cleaning and calibrating help, some projects need a more advanced machine.

High-resolution printers, like SLA or DLP models, are great for fine details and smooth surfaces. These printers use resin and light to make thinner layers than FDM printers. For example, SLA printers can create layers as thin as 25 microns, perfect for jewelry or dental models.

Before buying, think about your needs. If you often work on detailed projects, a high-resolution printer is worth it. Sovol 3D printers offer great options for precision and quality without being too expensive. They are good for both beginners and professionals.

Upgrading also gives you new features. Many high-resolution printers have better software, work with more materials, and are more stable. These features improve resolution and save time on troubleshooting.

Note: Check your current printer’s limits before upgrading. If it can’t meet your needs for detail and precision, a high-resolution printer will make a big difference.

Tips for Achieving High Resolution in 3D Printing

Trying advanced slicer settings

Advanced slicer settings can make your prints look better. Adjusting these settings helps create smoother surfaces and finer details. Start with layer height. Thin layers, like 0.1mm, show small details clearly. For even better resolution, use 0.05mm layer height, as slicers like Cura suggest. Thin layers take longer to print, so use them for detailed projects.

Other settings, like print speed and wall thickness, also matter. Slower speeds let the printer place material more accurately, reducing mistakes. Thicker walls make prints stronger and look nicer. If you have a Sovol printer, like the Sovol SV07 Plus, changing these settings can improve resolution and print quality.

Tip: Test different slicer settings on small prints first. This helps you find the best setup for your printer and material.

Adding supports and brims for stability

Supports and brims help keep prints steady, especially for tricky designs. Supports hold up overhanging parts, stopping them from sagging or bending. Brims make the base wider, helping the model stick to the bed better. This prevents warping and keeps the print stable.

Pick the right support type for your design. Tree supports work for detailed models, while grid supports fit simpler shapes. Adjust brim width in slicer settings to match your print size. Carefully remove supports and brims after printing to avoid damaging your model.

Note: Use supports only where needed to save time on cleanup.

Reducing vibrations and keeping the printer steady

Vibrations can mess up layers and lower resolution. To fix this, place your printer on a strong, flat surface. Keep it away from moving things like fans or machines. A steady spot helps the printer make better layers and improves print quality.

Check belts and screws often. Loose belts can cause shaking, and loose screws may misalign parts. Tighten them to keep the printer stable. Adding vibration pads under the printer can also help reduce movement.

Tip: Keep your workspace tidy. A clean area helps you focus on making great prints.

Tips for Optimizing Sovol Printers

- Calibrate Often: Make sure the print bed is level and the extruder works well. Sovol printers have tools to help with easy calibration.

- Use Slicer Settings: Change wall thickness, infill, and supports in slicer software. Sovol printers work well with slicers like Cura.

- Keep It Steady: Put your printer on a strong surface to stop vibrations. This helps align layers and improves print quality.

- Try Different Settings: Test layer height, speed, and temperature combinations. Sovol printers are consistent, making it easy to find the best setup.

Tip: Beginners should use Sovol’s manual settings first. Adjust them slowly as you learn more.

Sovol 3D printers are easy to use and powerful. They are great for hobbyists and professionals who want high-quality prints. With the right settings, these printers can deliver amazing results.

Getting better 3D printing resolution helps make detailed and precise prints. It improves how your designs look and makes your projects unique. Important things like layer height, nozzle size, and calibration affect resolution. Using thinner layers and smaller nozzles shows more details. Calibrating your printer keeps prints consistent and accurate.

Changing printer settings can improve resolution. Try higher DPI for detailed designs or adjust layer height for smoother prints. Regular calibration keeps your printer working well and improves quality. These simple tweaks can make a big difference in your prints.

Tip: Use small test prints to find the best settings for your printer and material.

FAQ

What is the best layer height for detailed prints?

The best layer height depends on your printer and project. For more detail, use a layer height of 0.1mm or less. This makes smoother surfaces and clearer details. But smaller heights take longer to print. Try different heights to find what works best for you.

How does nozzle size change print quality?

Nozzle size affects how detailed your prints can be. Small nozzles, like 0.2mm, make sharper details and smoother prints. Big nozzles, like 0.6mm, print faster but lose detail. Pick a nozzle size based on how complex your design is.

Can I make prints better without buying a new printer?

Yes, you can improve prints by changing settings. Adjust layer height, speed, and temperature. Use good materials and keep your printer clean and calibrated. These steps help make better prints without needing a new machine.

Why do my prints show lines between layers?

Lines between layers happen when layers are too thick or the printer isn’t set up right. Use a smaller layer height to hide the lines. Check if the print bed is level and the material flow is correct. Good calibration makes prints smoother.

Are resin printers better for detailed prints?

Resin printers, like SLA or DLP types, are great for detailed work. They make thinner layers and finer details than FDM printers. If you need smooth finishes or tiny designs, resin printers are a good choice.

Legg igjen en kommentar

Alle kommentarer blir moderert før de blir publisert.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.