When you want great 3D prints, understanding 3D printing tolerance is very important. It helps parts fit well and match the design correctly. Studies show some 3D printers have only 0.14% error, which means they can be very accurate and precise. Bigger parts often have no noticeable errors. Setting the right 3D printing tolerance significantly improves print quality. By learning this, you waste less, make better models, and create dependable designs.

Key Takeaways

- Knowing 3D printing tolerance helps make parts that fit well.

- Keeping your 3D printer clean and adjusted improves accuracy and saves material.

- Picking the right material, like PLA, helps with precise prints.

- Simple designs and planning for tolerances make parts fit better.

- Testing and improving prints step by step gives great results.

Understanding 3D Printing Tolerance

What is 3D printing tolerance?

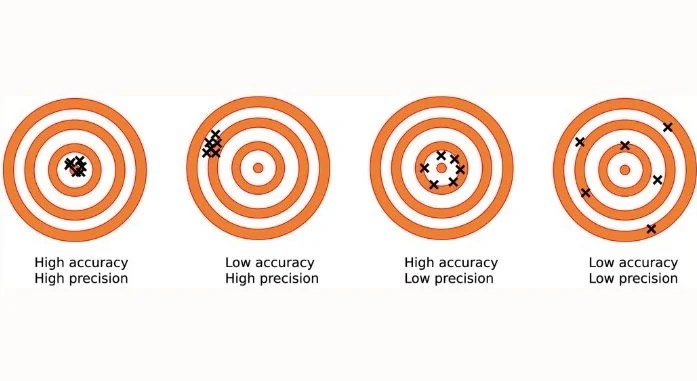

3D printing tolerance means how much a printed part can differ from its design. It shows how close the printed object is to the planned size. Tolerances are written as ranges, like ±0.1 mm, which tells the allowed difference from the design.

Different 3D printers have different levels of accuracy. For example, metal 3D printing (DMLS) can be very precise, with tolerances as small as ±0.003 inches for the first inch. SLS printers are less precise, with tolerances of ±0.010 inches. Below is a table showing tolerances for common 3D printing methods:

|

3D Printing Type |

X/Y Tolerances |

Z Tolerances |

|---|---|---|

|

Metal 3D Printing (DMLS) |

±0.003 in. (±0.0762mm) |

±0.006 in. (±0.1524mm) |

|

SLA |

±0.002 in. (±0.0508mm) |

±0.005 in. (±0.127mm) |

|

MJF |

±0.012 in. (±0.3048mm) |

±0.012 in. (±0.3048mm) |

|

SLS |

±0.010 in. (±0.254mm) |

±0.010 in. (±0.254mm) |

|

PolyJet |

±0.005 in. (±0.127mm) |

±0.005 in. (±0.127mm) |

Knowing these tolerances helps you pick the best printer for your project. It also ensures your parts are accurate enough for their purpose.

Why is 3D printing tolerance important?

Tolerances are key to making sure your 3D printed parts work well. They decide if parts fit together and function properly. For example, interlocking pieces need precise tolerances to avoid misalignment or failure.

Good tolerances save time and reduce waste. Accurate prints mean fewer mistakes and less material loss. This is especially important in industries like aerospace, cars, and healthcare, where precision matters a lot.

A study on printed versus machined holes in PEI Ultem 9085 FDM parts shows why tolerances matter. It found that adjusting settings like layer height and print speed improves accuracy. By focusing on tolerances, you can make better designs and reliable parts.

Common tolerance issues in 3D printing

Even with advanced printers, tolerance problems still happen. These issues can come from poor calibration, material behavior, or environmental changes. Here are some examples:

|

Example |

Problem |

Details |

|---|---|---|

|

Luxury Car Company |

Calibration |

Bad calibration caused uneven parts and waste. |

|

Electronics Manufacturer |

Material Issues |

Heat made new materials expand, causing errors. |

|

Sports Gear Startup |

Environment |

UV light and heat damaged materials, lowering safety. |

To prevent these problems, maintain your printer regularly. Pick materials that stay stable under heat and stress. Control the environment where you print to avoid damage.

Ignoring tolerances can lead to parts that don’t fit or work right. This affects how things are put together and their overall performance. Fixing these problems helps you make accurate and dependable 3D printed parts.

Factors Affecting 3D Printing Tolerances

Printer type and hardware capabilities

The kind of 3D printer you use matters a lot. Different printers have different precision levels. For example, SLA printers can handle tolerances of ± 100 µm. PµSL printers are more precise, with tolerances of ± 10 µm to ± 25 µm. Below is a table comparing tolerances for popular printers:

|

3D Printer Category |

Achievable Tolerance |

|---|---|

|

Standard Stereolithography (SLA) |

± 100 µm (0.1 mm) |

|

Material Jetting (MJ) |

± 300 µm (0.3 mm) |

|

Digital Light Processing (DLP) |

± 300 µm (0.3 mm) |

|

Projection Micro Stereolithography (PµSL) |

± 10 µm (0.01 mm) to ± 25 µm (0.025 mm) |

If you need accurate parts, pick a precise printer. Regular cleaning and calibration also keep your printer working well.

Material properties and their influence on tolerances

The material you use affects how accurate your prints are. PLA has low shrinkage, so it’s good for tight tolerances. ABS and nylon shrink more, which can cause warping or errors. Here’s a table showing how materials affect tolerances:

|

Material |

Shrinkage Rate |

Impact on Tolerances |

|---|---|---|

|

PLA |

Low shrinkage, easy to keep accurate |

|

|

ABS |

0.4 - 0.7% |

More shrinkage, may warp |

|

Nylon (SLS) |

1.5 - 2% |

High shrinkage, needs adjustments |

|

Metals (DMLS) |

0.1 - 0.3% |

Shrinks when cooling, needs design changes |

To get better tolerances, choose the right material. Adjust your design or printer settings to match the material.

Design complexity and dimensional accuracy

Complicated designs can make it harder to stay accurate. Thin walls or tricky shapes may not print as planned. Overhangs or unsupported parts might sag, causing errors. Simplify your design or add supports to improve accuracy. Using SLA or PµSL printers can help with detailed designs. Always think about tolerances when designing to ensure parts fit and work properly.

Calibration and maintenance of 3D printers

Taking care of your 3D printer is very important. Regular checks help it make accurate parts. If you skip maintenance, prints may turn out wrong. This wastes both time and materials. Follow simple steps to keep your printer working well.

First, do regular calibration tests. A Dimensional Accuracy Test checks if parts are the right size. This is needed for pieces that must fit together perfectly. A Full Bed Dimensional Accuracy Test ensures the whole print bed stays accurate. This is helpful for big or multi-piece prints.

Next, look for mechanical problems that can hurt print quality. Use a Z Wobble Test to find loose screws or misaligned parts. Fixing these makes your printer more stable and reduces mistakes.

Adjusting print settings is also important. Run a Retraction Performance Test to fix stringing issues. This improves how smooth your prints look. Use a Support Material Test to set up supports correctly. Good supports are easy to remove and leave clean parts.

Keep your printer clean to avoid problems. Wipe dust off the print bed and extruder. Lubricate moving parts to stop them from wearing out. Write down your maintenance tasks to know when repairs are needed.

Tip: Check your printer every month to find problems early. Regular care makes your printer last longer and gives better results.

By focusing on calibration and maintenance, you’ll get accurate prints and save time.

Optimizing 3D Printing for Perfect Fit

Regular maintenance and calibration practices

To make sure your 3D printed parts fit well, keep your printer in good shape. Regular maintenance and calibration are very important. A clean and well-maintained printer works better and makes fewer mistakes. Calibration helps your printer create parts that match the design, so you don’t have to reprint them.

Check your printer often. Clean the print bed to help parts stick properly. Remove dust or dirt from the extruder. Lubricate moving parts to stop them from wearing out. Tighten belts and screws because loose parts can cause errors.

Calibration is also key. Use a dimensional accuracy test to check if your printer makes parts the right size. For bigger projects, do a full bed accuracy test to ensure the whole print area is correct. These steps improve your printer’s accuracy and make it last longer.

|

Evidence Type |

Description |

|---|---|

|

Optimizing Printer Calibration |

Regular calibration keeps print quality steady for all projects. |

|

Batch Testing |

Testing groups of prints helps find and fix tolerance problems early. |

|

Standardizing Material Handling |

Managing materials well ensures high-quality 3D printing results. |

By following these maintenance and calibration tips, your printer will work better, and your 3D prints will turn out great.

Adjusting slicing settings for better tolerances

Slicing settings are very important for improving 3D printing accuracy. Changing these settings can make your prints more precise. For example, turning on exact flow lets you control how much filament comes out, making parts more accurate. Coasting stops filament flow a little early, which reduces errors and helps parts fit better.

Another helpful setting is adaptive layers. This changes the layer thickness based on your model’s surface. It makes surfaces smoother and saves time. These changes help you get better results and avoid mistakes.

|

Slicing Setting |

Effect on Precision |

|---|---|

|

Controls filament flow for better accuracy and quality. |

|

|

Enable Coasting |

Stops filament early to reduce errors and improve fit. |

|

Adaptive Layers |

Adjusts layer thickness for smoother surfaces and faster printing. |

You can also change the extrusion width. Setting it to 120% of the nozzle size improves strength and detail. This is great for parts like snap-fit pieces or screws where accuracy is very important.

Tip: Try different slicing settings to see what works best for your printer and material. Small changes can make a big difference in how well your parts fit.

Selecting the right material for precision

Picking the right material is very important for accurate 3D printing. Different materials shrink differently, which affects how precise your prints are. PLA doesn’t shrink much, so it’s good for tight tolerances. ABS and nylon shrink more, which can cause warping or errors.

Advanced methods like Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) are very precise. MJF has tolerances of about ± 0.2% or ± 0.2 mm, making it great for detailed parts. SLS offers tolerances of ± 0.3% or ± 0.3 mm, which is also very reliable.

- Multi Jet Fusion (MJF): Very precise with tolerances of ± 0.2% or ± 0.2 mm.

- Selective Laser Sintering (SLS): Reliable with tolerances of ± 0.3% or ± 0.3 mm.

- Both methods use strong thermoplastic powders like polyamide (PA), which makes parts tougher and more durable.

When choosing a material, think about what your project needs. For parts that need to be strong and accurate, pick materials that match those requirements. By understanding how materials behave and adjusting your design, you can make better, more reliable 3D prints.

Designing with tolerance considerations in mind

When creating designs for 3D printing, think about tolerances early. This helps parts fit well and work as planned. Skipping this step can cause misaligned parts, wasted material, and extra work.

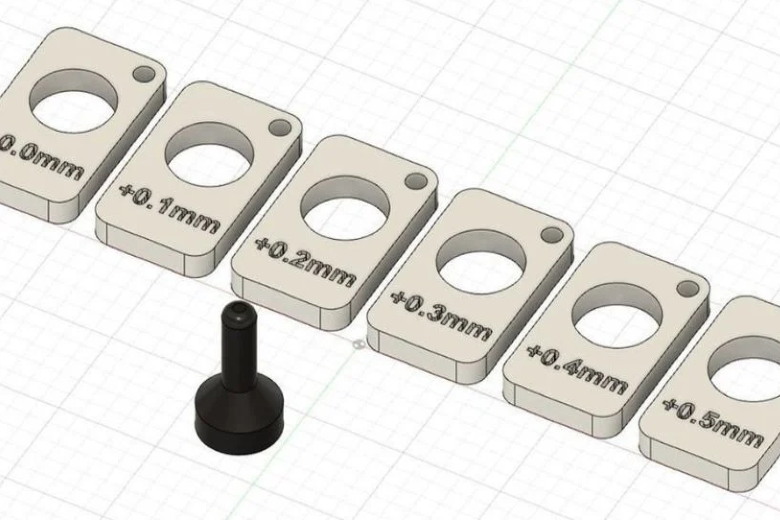

First, know your printer’s and material’s tolerances. For example, if your printer has a ±0.1 mm tolerance, design with that in mind. Leave space between parts that connect to avoid tight fits. For snap-fit designs, test different tolerances to find the right mix of strength and flexibility.

Keep designs simple to improve accuracy. Avoid thin walls or tricky overhangs that might warp during printing. For moving parts like gears or hinges, add extra space for material changes like shrinking or expanding. Use CAD software to test and adjust tolerances before printing.

Here are examples showing how good tolerance design helps:

|

Industry |

Case Study Description |

Benefits Achieved |

|---|---|---|

|

Automotive |

Used tolerance analysis for engine parts. |

Better fuel use, fewer emissions, more reliable engines. |

|

Aerospace |

Checked tolerances for aircraft parts. |

Safer flights and better performance. |

|

Electronics |

Improved tolerances in circuit boards. |

Stronger signals, less rework, and better product function. |

One example is the Cummins Engine Case Study. Engineers fixed assembly issues in a Linear Belt Tensioner using tolerance analysis. They found a 16% problem rate and improved it with feedback and data. This shows why thinking about tolerances during design is so important.

By focusing on tolerances, you’ll make fewer mistakes, save time, and create reliable parts.

Using Sovol 3D printers for high-precision results

Sovol 3D printers are great for making accurate prints. They are easy to use and work well for beginners and experts. If you want better results, Sovol printers have many helpful features.

The Sovol SV08 is very precise. It prints small, detailed parts that fit perfectly. Its Core XY design and Klipper firmware improve stability and accuracy. The Z-axis motors keep layers aligned, making it great for tight tolerances.

Here’s what makes the Sovol SV08 stand out:

|

Evidence Description |

Details |

|---|---|

|

High Accuracy in Printing |

Made small, detailed parts that fit perfectly. |

|

Advanced Design Features |

Core XY design, Klipper firmware, and stable Z-axis motors. |

|

Effective Support Handling |

Managed tricky supports without problems. |

|

Dual-Color Filament Capability |

Printed two-color designs with great detail and quality. |

Sovol printers are also easy to use. Their strong build and simple controls mean fewer adjustments. Whether you’re making a prototype or a working part, these printers give steady, high-quality results.

If you need precise tolerances, Sovol 3D printers are a smart choice. Their advanced features and reliable performance make them a great tool for any project.

Testing and Measuring Printing Tolerances

Tools for measuring tolerances (e.g., calipers, micrometers)

To check tolerances, you need proper tools. Calipers and micrometers are great for measuring 3D-printed parts. Calipers can measure inside, outside, and depth sizes. Digital calipers are very accurate, often showing results to 0.01 mm. This makes them useful for checking tight tolerances. Micrometers are even more precise, measuring small details up to 0.001 mm.

For advanced checks, use tools like surface scanners or CT scans. These create detailed 3D models of your parts. You can compare these models directly to your design.

A study looked at ways to measure 3D-printed heart models. It found that CT scanning solves many problems other methods face. CT scans allow direct comparison of the printed model to the patient’s anatomy.

Techniques for testing dimensional accuracy

Testing accuracy ensures parts match the design. Start by printing a test object, like a calibration cube. Use calipers or micrometers to measure it. Check for size differences and adjust your printer settings if needed.

A study compared SLA and FDM printers using jaw models. It showed both methods work well in dental practice. FDM prints were as accurate as SLA prints.

FDM prints may need extra steps like sanding to meet strict tolerances. Advanced control methods in 3D printing also improve accuracy.

- FDM parts often need extra work to meet standards.

- Advanced control methods help improve FDM accuracy.

Iterative testing and refining for a perfect fit

Getting a perfect fit takes testing and improving. Print a prototype, measure it, and find areas to fix. Change your design or printer settings and try again until it fits right.

Some methods make this process easier. Techniques like Simulated Annealing and Genetic Algorithms improve designs by testing and refining them. These are helpful for complex projects needing high precision.

|

Methodology |

Description |

|---|---|

|

Simulated Annealing |

Finds the best solution by testing many options. |

|

Particle Swarm Optimization (PSO) |

Uses group behavior to explore and find good solutions. |

|

JAYA Algorithm |

A simple method that improves solutions without extra settings. |

|

Teaching Learning Based Optimization |

Mimics teaching to improve solutions through learning and sharing. |

|

Cohort Intelligence |

Uses group intelligence to solve hard problems. |

|

Genetic Algorithms |

Copies evolution to improve designs over time. |

By using these methods with careful testing, you can improve your 3D printing process and get great results.

Learning about 3D printing tolerance is key to making accurate parts. Knowing about printer types, materials, and design can help improve prints. The table below shows important factors that affect tolerances and tips to make them better:

|

Factor |

What It Means |

|---|---|

|

Printing Technology |

FDM, SLA, and SLS printers have different accuracy levels. |

|

Material Properties |

Materials can shrink, warp, or expand, changing tolerances. |

|

Design Considerations |

Shapes, features, and how parts are placed affect accuracy. |

|

Post-Processing |

Sanding and polishing can improve fit and surface quality. |

|

Tips for Optimization |

Learn your printer’s limits, design carefully, test often, and adjust settings for better results. |

To get the best prints, keep your printer calibrated, pick the right materials, and plan designs with tolerances in mind. Sovol 3D printers are a great choice for precise and reliable printing. Use these tips now to make your 3D printing projects even better!

FAQ

How can I measure 3D printing tolerances?

Use tools like calipers or micrometers to check sizes. Calipers are good for basic measurements. Micrometers work better for tiny details. For tricky parts, try a 3D scanner to compare the print to the design.

How do I stop warping in 3D prints?

Pick materials like PLA that shrink less. Make sure the print bed is heated and parts stick well. Keep the room temperature steady while printing. Adding brims or rafts can help keep the print stable.

Why don’t my 3D printed parts fit together?

Parts may not fit because of wrong tolerances or bad settings. Check your printer’s flow rate and layer height. Change your design to leave space for moving parts. Regular printer care keeps prints accurate.

What materials are best for precise 3D printing?

PLA is great for accuracy because it doesn’t shrink much. PETG and ABS are stronger but shrink more, so plan for that. Materials like polyamide (SLS) or metal powders (DMLS) are very precise for big projects.

How often should I calibrate my 3D printer?

Calibrate your printer every month or after heavy use. Run tests like size checks and Z wobble tests to keep it working well. Regular calibration stops mistakes and makes prints better, especially for tight fits.

Hagyj egy megjegyzést

Az összes megjegyzés moderálódik, mielőtt közzéteszik.

Ezt a webhelyet a hCaptcha rendszer védi, és a hCaptcha adatvédelmi szabályzata, valamint szolgáltatási feltételei vonatkoznak rá.